You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Motor Mounts

- Thread starter cuda620

- Start date

-

Professor Fate

Push the button, Max...

Professor Fate

Push the button, Max...

So, are you looking for just the poly mounts (isolators) or the engine brackets also to do the swap? If looking for the brackets, do you have a slant six or smallblock k frame?They’re not for swapping the bigblock into an A body. Thanks

Professor Fate

Push the button, Max...

Then this:Smallblock

Engine Performance & Vehicle Customizing Products From Hedman | Hedman Performance Group

These come with rubber isolators. If you MUST have polys, use the ones I referenced above with this kit (post #2).

Last edited:

Professor Fate

Push the button, Max...

???

MOPAR B/RB into1967-72 A-BODY (with SB V8 K-member) Motor Mount Kit

Engine Mount Kit With Pads For Installing a MOPAR B/RB Engine into a 1967-72 MOPAR A-BODY (with SB V8 K-member)

Part#4698

$66.91

Find Local Dealer

MOPAR B/RB into1967-72 A-BODY (with SB V8 K-member) Motor Mount Kit

Engine Mount Kit With Pads For Installing a MOPAR B/RB Engine into a 1967-72 MOPAR A-BODY (with SB V8 K-member)

Part#4698

$66.91

Find Local Dealer

Professor Fate

Push the button, Max...

From the TransDapt specs:

USES MOUNT PAD #TD 4221; OE pads for 69-71 Dodge D/W-Series truck (225/3.7L) (ie: 2266, 602266)

From the Polybushings.com site:

If your normal auto parts store says

your mount is number #2265, #2266

or #2469 then this mount will fit your car

or truck.

USES MOUNT PAD #TD 4221; OE pads for 69-71 Dodge D/W-Series truck (225/3.7L) (ie: 2266, 602266)

From the Polybushings.com site:

If your normal auto parts store says

your mount is number #2265, #2266

or #2469 then this mount will fit your car

or truck.

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

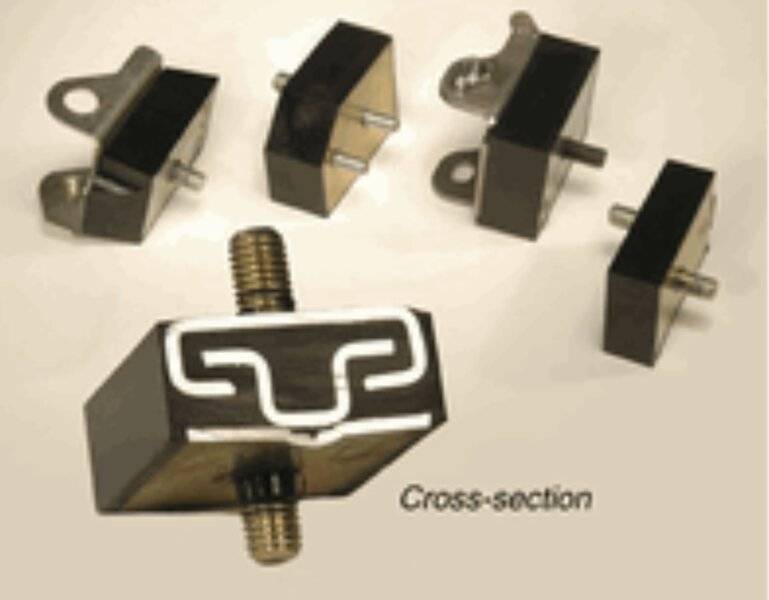

Imo, do not use poly-loc engine mounts.

I've stated it many times, poor design, each side within the poly can easily slide past each other, that's why some versions have external braces built into each side.

Braces or not, torque strap or not, the poly gets pummeled, destroyed inside and actually reduces the width of the mount lowering the engine. It also can be seen blowing out the top and bottom, looks like a smore of poly.

I've stated it many times, poor design, each side within the poly can easily slide past each other, that's why some versions have external braces built into each side.

Braces or not, torque strap or not, the poly gets pummeled, destroyed inside and actually reduces the width of the mount lowering the engine. It also can be seen blowing out the top and bottom, looks like a smore of poly.

Professor Fate

Push the button, Max...

No prob.It appears that I am Wrong. I stand Corrected. Thank you very very much for ur help. As u have put a lot of research into this and it helps me a lot. So many others wouldn’t have.

Hope it all works out for you.

Ur suggestions?Imo, do not use poly-loc engine mounts.

I've stated it many times, poor design, each side within the poly can easily slide past each other, that's why some versions have external braces built into each side.

Braces or not, torque strap or not, the poly gets pummeled, destroyed inside and actually reduces the width of the mount lowering the engine. It also can be seen blowing out the top and bottom, looks like a smore of poly.

View attachment 1715624799

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

Buy standard rubber, drill a hole through it and the steel mounts, stick a bolt through it, screw a lock nut down right before it's tight, done.

A number of members have done this, some use a flat head countersunk bolt.

A number of members have done this, some use a flat head countersunk bolt.

Is there room to do this? I’ve not seen the mounts.Buy standard rubber, drill a hole through it and the steel mounts, stick a bolt through it, screw a lock nut down right before it's tight, done.

A number of members have done this, some use a flat head countersunk bolt.

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

I have bolts through both my mounts.

Driver's side has plenty of room, original bb car, here is a reference: Best Place to Buy Motor Mounts For my 383 Formula S.

I'm sure the countersunk bolt head helps.

I used the same method for the passenger side, iirc the only issue was I had to shave off one side of the bolt head on the top for clearance, which also helped to hold the bolt in place.

I found only 'controlling' the driver's side mount wasn't enough, as once I did the passenger side failed.

I have a tunnel ram so it was quite obvious when the mounts would fail. Once my driver's side was secure, the passenger side failed and the carbs were in contact with the hood.

Imo, the engine isn't technically lifting on the driver's side, it's twisting.

Driver's side has plenty of room, original bb car, here is a reference: Best Place to Buy Motor Mounts For my 383 Formula S.

I'm sure the countersunk bolt head helps.

I used the same method for the passenger side, iirc the only issue was I had to shave off one side of the bolt head on the top for clearance, which also helped to hold the bolt in place.

I found only 'controlling' the driver's side mount wasn't enough, as once I did the passenger side failed.

I have a tunnel ram so it was quite obvious when the mounts would fail. Once my driver's side was secure, the passenger side failed and the carbs were in contact with the hood.

Imo, the engine isn't technically lifting on the driver's side, it's twisting.

have to agree after blowing 3 sets of poly mountsImo, do not use poly-loc engine mounts.

I've stated it many times, poor design, each side within the poly can easily slide past each other, that's why some versions have external braces built into each side.

Braces or not, torque strap or not, the poly gets pummeled, destroyed inside and actually reduces the width of the mount lowering the engine. It also can be seen blowing out the top and bottom, looks like a smore of poly.

View attachment 1715624799

GunslingerFIN

Well-Known Member

This is tad old thread, but seems appropriate place to ask: do 2265 and 2469 motor mounts interchange? I have -65 Valiant with blown 360 and the motor mounts are just completely shot. Long term plan is to move into solid mounts, but I need to replace the mounts before spring just to get the car running and driving again. I think that having 2469 mount at least on drivers side could limit the twist. Polybushings.com states that their poly-mount would be replacement for both 2265 and 2469 so that makes me think that I could replace the 2265 mount with 2469 for now? For the record, the car is "old school" race car and does have chain bolted to engine on drivers side mount, but that seems not to be enough to stop the engine twisting (at least with the shot mounts).

EDIT:

For the solid mounts I'm looking for example these PLYMOUTH Moroso 62540 Moroso Solid Steel Motor Mounts | Summit Racing

With that price I could order and swap those in right away, if I could be sure that they in fact fit the Valiant with 360 and will be direct replacement for current mounts.

EDIT:

For the solid mounts I'm looking for example these PLYMOUTH Moroso 62540 Moroso Solid Steel Motor Mounts | Summit Racing

With that price I could order and swap those in right away, if I could be sure that they in fact fit the Valiant with 360 and will be direct replacement for current mounts.

Last edited:

-