Alecb

Well-Known Member

The old plastic rollers that were on the passenger side window of my 73 Duster were broken and no longer held my glass in place. The window would bounce around when you closed the door, and I had to tell people not to slam the passenger door because I was afraid of the window shattering. Thankfully that did not happen and I was able to get new rollers installed, here is how I did it.

First I had to remove the door panel, door glass, and window mechanism. These original rollers were found at the bottom of the door and in the roller tracks.

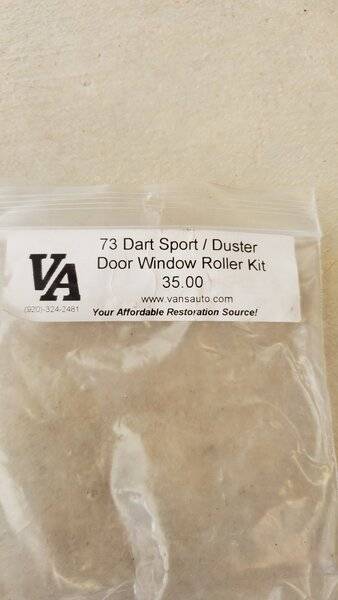

This was the kit that I bought from eBay.

Once I had new rollers I pulled out the window mechanism and removed the old roller posts. I did this using a hammer to push the cone part up just enough to get a hacksaw blade in and sawed away the old posts.

Once all of those were out, I installed the new ones by inserting them into their holes, DONT FORGET WHICH WAY THEY FACE! Then I used a hammer to smash the ends into mushrooms and put some epoxy over that just as extra security. This may not be the correct way to do this, but I'll let future me deal with that in 50 years.

While the window is out, it's a good opportunity to clean the whole thing. Mine was filthy!

First I had to remove the door panel, door glass, and window mechanism. These original rollers were found at the bottom of the door and in the roller tracks.

This was the kit that I bought from eBay.

Once I had new rollers I pulled out the window mechanism and removed the old roller posts. I did this using a hammer to push the cone part up just enough to get a hacksaw blade in and sawed away the old posts.

Once all of those were out, I installed the new ones by inserting them into their holes, DONT FORGET WHICH WAY THEY FACE! Then I used a hammer to smash the ends into mushrooms and put some epoxy over that just as extra security. This may not be the correct way to do this, but I'll let future me deal with that in 50 years.

While the window is out, it's a good opportunity to clean the whole thing. Mine was filthy!