833 Transmission won't disengage at stop after 100 miles.

Just got the car back on the ground yesterday and did a test lap around the hood. 3-4 feels really smooth. 1-2 feels like it needs a linkage adjustment. It feels bumpy in the shift knob. It takes 10 X longer to jack the car up to set it on the wheel cribs so I can get under it than it does to turn the shift linkage one turn longer. :BangHead: I bought the wrong 100 year old house, I guess. Back when I was a kid, most all the garages had grease pits in the garage floor that you just parked over the top of.

My old input shaft pilot bushing was adhered to the crankshaft like nobodies' business. I filled the opening with grease and used a 3/4" brass drift to try to remove the old bushing. The vibration on the drift and hammer was like I was pounding on the end of the crankshaft instead of the compressed grease. Not finding a puller that was not a slide hammer, I cut two grooves in the bushing and taped it between the grooves with a cold chisel. That broke a tab out of the bushing about 1/4" wide x 3/8" deep. That was enough to allow the bushing to easily come out with grease and the brass drift. No vibration at all, it just pushed out.

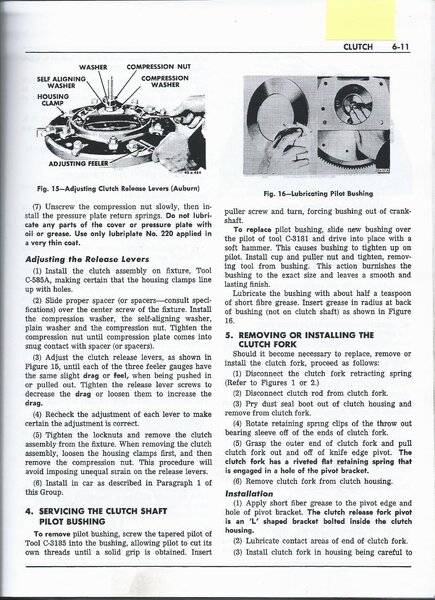

I found two references in the Dodge Technical Service Manual concerning grease at the pilot bushing. One in the CLUTCH chapter, last paragraph of section 4;

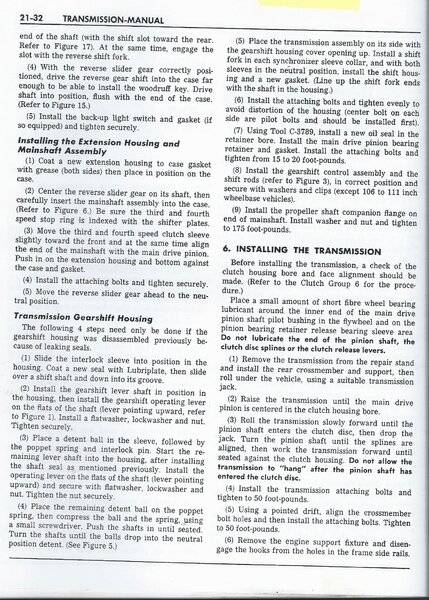

and the other in the TRANSMISSION chapter, second paragraph of section 6;

Hopefully I don't go to Hell for scanning a full page from a copy righted manual.

:mob:

Two of the coolest tricks I used to install the transmission besides borrowing a buddies' transmission jack, was 1) Make two housing alignment pins out of bolts with the heads cut off and a screwdriver slot cut into the ends to put in the bottom of the bell housing, and 2) Ask the little woman to step on the clutch pedal after the transmission was sitting on the alignment pins. Even with the friction plate alignment tool, pressing on the clutch pedal made it sooo much easier!:D

I've finally given up on cleaning and crimping the old fuse box. Once I figure out the replacement fuse box, and have brake lights again, I'll get to finish adjusting the shift linkage.

:steering:

Just got the car back on the ground yesterday and did a test lap around the hood. 3-4 feels really smooth. 1-2 feels like it needs a linkage adjustment. It feels bumpy in the shift knob. It takes 10 X longer to jack the car up to set it on the wheel cribs so I can get under it than it does to turn the shift linkage one turn longer. :BangHead: I bought the wrong 100 year old house, I guess. Back when I was a kid, most all the garages had grease pits in the garage floor that you just parked over the top of.

My old input shaft pilot bushing was adhered to the crankshaft like nobodies' business. I filled the opening with grease and used a 3/4" brass drift to try to remove the old bushing. The vibration on the drift and hammer was like I was pounding on the end of the crankshaft instead of the compressed grease. Not finding a puller that was not a slide hammer, I cut two grooves in the bushing and taped it between the grooves with a cold chisel. That broke a tab out of the bushing about 1/4" wide x 3/8" deep. That was enough to allow the bushing to easily come out with grease and the brass drift. No vibration at all, it just pushed out.

I found two references in the Dodge Technical Service Manual concerning grease at the pilot bushing. One in the CLUTCH chapter, last paragraph of section 4;

and the other in the TRANSMISSION chapter, second paragraph of section 6;

Hopefully I don't go to Hell for scanning a full page from a copy righted manual.

:mob:

Two of the coolest tricks I used to install the transmission besides borrowing a buddies' transmission jack, was 1) Make two housing alignment pins out of bolts with the heads cut off and a screwdriver slot cut into the ends to put in the bottom of the bell housing, and 2) Ask the little woman to step on the clutch pedal after the transmission was sitting on the alignment pins. Even with the friction plate alignment tool, pressing on the clutch pedal made it sooo much easier!:D

I've finally given up on cleaning and crimping the old fuse box. Once I figure out the replacement fuse box, and have brake lights again, I'll get to finish adjusting the shift linkage.

:steering: