Hello everyone , hope your all safe. I have clutch fork ratio problem. 73 duster was a slant car now has 73 340 4 speed. Got it as unfinished project. Clutch issue, pedal almost to floor to dissengage. All adjustments tried new linkage clips and washers . Bell housing is an oddball lakewood dyno bellhousing. Has multiple bolt patterns for small block, big block And hemi. I checked fork 12-1/2” ok. Has light duty clutch pedal with small over center spring 10-1/2 diaphragm clutch . Called lakewood. Dyno bell built just like regualr bell dimensions except for extra bolt patterns and extra dyno mount holes. I changed pivot because looked like big block pivot. Got brewers pivot A body to 1975. It was hard to take fork out of pivot had tp pry it. Put in new pivot fork hits too low on throwout bearing ears to clip in. Any ideas ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Got forked

- Thread starter mikec

- Start date

-

There are different size clutch rods, long and short, that go from Z bar to clutch fork. There is one for A Body A engine and E bodies 1 for A engine and 1 for B engine. Maybe look up Year one to see if they list sizes. Never had a problem with fork clip always used what came in bell housing and have done B engine and a Hemi in an E body .

common issue. You may need to make a spacer for the mounting pad where the fork pivot bolts to the bellhousing. My lakewood needed one to put the pivot closer to the flywheel for the swing to work properly.

If you had a working set up with a stock bell, measure from the face of flywheel to the pivot point. Make sure the lakewood is the same distance.

If you had a working set up with a stock bell, measure from the face of flywheel to the pivot point. Make sure the lakewood is the same distance.

Thanks Tonysrt, crackedback, Outsider, for some insight into this problem . It is hard to tell from pics, but my clutch fork bottoms to housing now without linkage on and End of fork hitting bearing ears too low. Ithink Z bar is correct its the shorter width one, the pivot that was in the bell is the smaller of the two, i'm going to see if i can get a measurement for flywheel to pivot , has to be some specs out there in a manual . Think i have some steel to make a spacer put it with smaller pivot . Going to see if i can get better easurements too Thanks

Daves69

Well-Known Member

Are you saying the new pivot is too high or the pivot is too far away for the fork to rest on the release bearing pads?

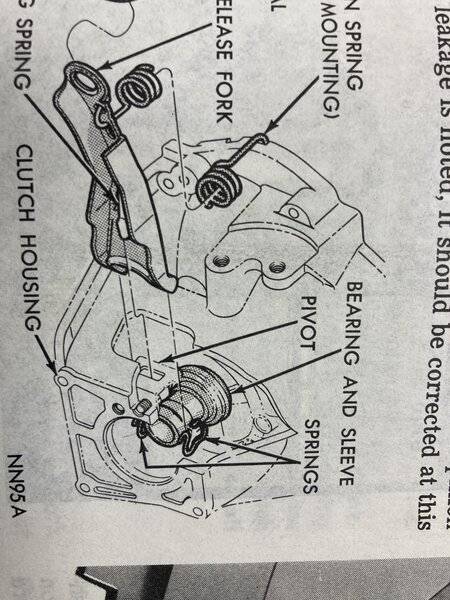

Not sure it helps ya'. I have these pictures of the pivot came in MP's SB fork kit..........

Not sure it helps ya'. I have these pictures of the pivot came in MP's SB fork kit..........

Hey Daves69 saw the pics and forgot about fork lol I think the pivot is too high and maybe to far away from input shaft , the other pivot I think is a big block pivot B body its a little lower and the base shallower , . not sure if it would need to be set up for a block saver. Because its for a dyno, no clutch, I don't think they use a block saver

Your missing the front of the bell housing. Look how far the fork is front. It actually looks like its worn into the bell. You would never get the boot on there . Right there is your geometry problem.

Daves69

Well-Known Member

Mike,

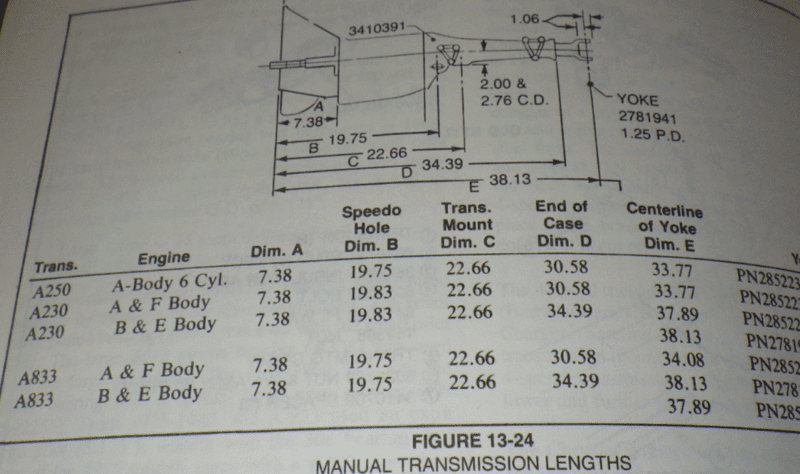

The bell O/A length for a stock bell housing is 7.380" per MP Chassis book I do believe. If the bell you have is shorter, it can be an issue for pivot height if the pivot mounting boss/pad does not compensate for the difference. On my old LW housing, I needed to add a 1/8" to adjust for the block saver plate. An old Ansen plate I have is even thicker.

BTW, It appears to me your new pivot is like the one in the pictures I posted.

The bell O/A length for a stock bell housing is 7.380" per MP Chassis book I do believe. If the bell you have is shorter, it can be an issue for pivot height if the pivot mounting boss/pad does not compensate for the difference. On my old LW housing, I needed to add a 1/8" to adjust for the block saver plate. An old Ansen plate I have is even thicker.

BTW, It appears to me your new pivot is like the one in the pictures I posted.

Oldmanmaopar ,Thanks I beleive your right the fork and pivot is the problem like you can see in the pics , the pivot i took out allowed fork to travel but it must have been put in before trans, because it was really pressing against trans opening to get it out. the new pivot make s fork right up to the bell and can't angle anymore to get on bearing ears. there's no wear on bell but fork is against housing .Thanks again

Last edited:

Daves69 , THanks for the measurement , I will check my overall bell measurement today, I will see if i can get a flywheel to pivot base measurement also. wonder if there is a spec or measurement to check that as well. the pivot i put in is the one from brewers fp845 for A body small block for 1968-75 .It made pivot too high . and it moves pivot point away from input shaft a little too maybe 3/8". Brewers shows all the different pivots , maybe i can get some measurements and discuss pivot differences with Brewers as well. I have heard they are very helpful .

Daves69

Well-Known Member

That is probably your best bet. I don't have any dimensions on that pivot that was in the kit....maybe i can get some measurements and discuss pivot differences with Brewers as well....

How does your fork pivot point compare to my picture? Kinda' looks like 4-5/16" from the tip on my picture.

Online I see pictures of SB bells using different pivots on stock SB bells. ....

daves69 my pivot is just like the picture of yours two dimples in angle of pivot the two pics of bells have the same looking pivots as i have have . the right one is in now and too high, the one on left was the one in it but ratio is wrong with that one. maybe height is too low aybe a shim , going to do some measuring . thanks

Daves69

Well-Known Member

The bell picture I posted looks like the pivots are bolted to the housing thickness and not on a raised "pad or boss" as yours is.

Possibly the difference of a block saver plate? BTW, pushing that fork under all three springs at the same time can be a real PITA.

Possibly the difference of a block saver plate? BTW, pushing that fork under all three springs at the same time can be a real PITA.

THanks I saw a similar pic last night as well, think going to try a shim under the the shallower base pivot, the fork is hitting the bearing ears just below the clips, need to get fork a little higher to land on top of ears .It might be pivot a little off center as well bolt pattern on pivot favors one side. It is going to be a pia but its got to be done lol .

Haven't seen it mentioned, the pivot in the first picture, on the right, is for a 10 7/8" fork. I have tried both forks in my old Lakewood with a Centerforce II diaphragm clutch, not really acceptable. Too damn hard to push in.

cruze418 thanks for info on clutch fork , I am in process of using an 1/8 " shim just made one , under pivot . I have the 12-1/2" arm and without pivot , clips right in, so some measuring and guessing at pivot angle and i came up with shim. will post results after i get it in.

Don't know that a shim would do it, seems like I have a picture of both forks and pivots, going to look. Looked at your pictures again, the shiny one is your 12 1/2 pivot. I could not get the 12 1/2" to work in my Dart, '69, SB. Went back to the 10 7/8". Still have to modify the bellcrank like tti's.

No free lunch!

No free lunch!

A little off topic, but all of these interference issues. I had Hooker headers on my '69 Dart back in the day. No clutch interference issues, ran my stock gear reduction mopar starter ( I miss the sound, you know what I mean). The tti headers on my current Dart get in the way of everything, oil pan, scattershield, frame, clutch linkage, starter, and clocking the oil filter. It's like, what the hell is going on with my country?

Just saying

Just saying

All fixed. Had to pull trans because of lakewood bell no access to get fork and release bearing together. Good thing I did , found flywheel had lots of cracks , clutch disc was ok but had a weird wear pattern as well. Biggest issue I found was crank bushing was all chewed up, I cut out old one and found a second bushing that was so worn looked like part of crank. Got it out and put new bushing, flywheel,clutch assembly and bearing. I put the A body pivot in , everything went together nice. Clutch pedal is perfect and action is good .

That's kinda amazing, good thing you had to go in there . You can get the fork in and out, but it's very difficult, and patience is your friend. Good that you went in!

Update on mine, when I did all of the mods for the 10 7/8" fork, I neglected to have my starter in, in a hurry I guess. It's got the stock z bar in with the 12 1/2" fork now, but I believe that a hyd throw out bearing in my future.

Glad that you are good to go!

Update on mine, when I did all of the mods for the 10 7/8" fork, I neglected to have my starter in, in a hurry I guess. It's got the stock z bar in with the 12 1/2" fork now, but I believe that a hyd throw out bearing in my future.

Glad that you are good to go!

-