Instrument cluster refresh

Some other ramblings. Test the gauges when you are about done and make sure they work and are as accurate as you "think." You do this with a test resistor to simulate the sender

1....For sure go with a solid state IVR. Solder jumpers across the IVR contacts to the board traces. They lose contact

2...When installing gauges, loosen/ tighten the stud nuts several times to "scrub" the nut and board clean. They can lose contact there

3....Check carefully the harness connector pins for loose. Clean and solder around them if any question at all

4....Clean the board traces around the socket contacts, as well as the socket contacts themselves, and bend them for better spring action.

5....Install a long grounding pigtail onto one of the board grounding points and bolt the other end to the dash frame or column support. Grounding originally was "luck" through the mounting screws.

6...Ammeter. If you have done the ammeter bypass, fine. If not, inspect the guts of the ammeter carefully, and consider soldering the studs to the brass cross piece (shunt) in the ammeter. Inspect mounting hardware for heat damage, as well as the wire ends, if factory. And inspect and repair the bulkhead connector if you have not done so.

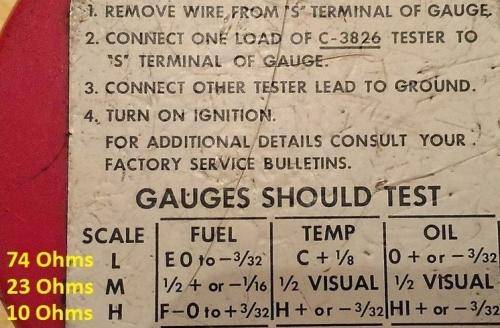

Gauge testing: Scare up some resistors or a rheostat or even fuel tank sender so you can adjust the resistance to the 3 set points for the test device. Provide power to the cluster and put the test resistors from the gauge sender connection to ground, one at a time. All two or three (Ralleye) gauges should read the same with each resistor

Some other ramblings. Test the gauges when you are about done and make sure they work and are as accurate as you "think." You do this with a test resistor to simulate the sender

1....For sure go with a solid state IVR. Solder jumpers across the IVR contacts to the board traces. They lose contact

2...When installing gauges, loosen/ tighten the stud nuts several times to "scrub" the nut and board clean. They can lose contact there

3....Check carefully the harness connector pins for loose. Clean and solder around them if any question at all

4....Clean the board traces around the socket contacts, as well as the socket contacts themselves, and bend them for better spring action.

5....Install a long grounding pigtail onto one of the board grounding points and bolt the other end to the dash frame or column support. Grounding originally was "luck" through the mounting screws.

6...Ammeter. If you have done the ammeter bypass, fine. If not, inspect the guts of the ammeter carefully, and consider soldering the studs to the brass cross piece (shunt) in the ammeter. Inspect mounting hardware for heat damage, as well as the wire ends, if factory. And inspect and repair the bulkhead connector if you have not done so.

Gauge testing: Scare up some resistors or a rheostat or even fuel tank sender so you can adjust the resistance to the 3 set points for the test device. Provide power to the cluster and put the test resistors from the gauge sender connection to ground, one at a time. All two or three (Ralleye) gauges should read the same with each resistor