PRH

Well-Known Member

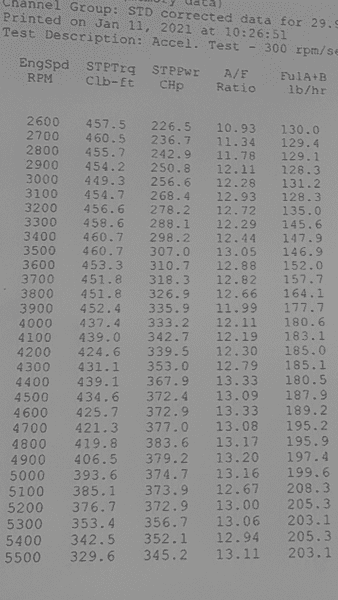

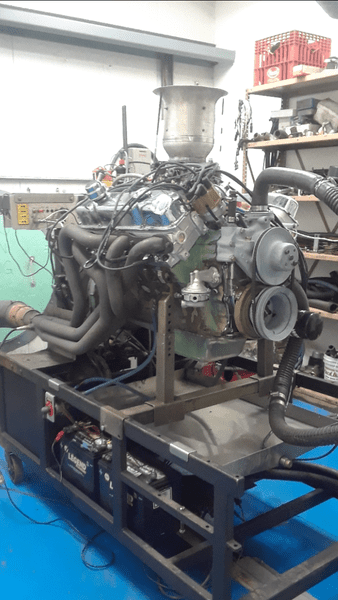

Along the same lines as the 7.5:1 build Jim LaRoy tested several years ago...... but this one steps up the CR a bit, and gets ootb Stealth heads instead of the factory pieces.

It’s a .030 440 with cast pistons down the hole .110”.

Small Summit cam(214/224-112), stock rockers and pushrods.

Stealth heads that have had the guides checked and the seats bumped with a stone. Zero porting.

Using all the hardware that came on the heads.

Stock 440 intake(casting number 3512501), 1” open carb spacer and an old 3310(750vs)carb, Hooker 1-7/8” headers.

Mopar ignition kit, timing 10* at idle/38* total.

CR works out to 8.7:1.

I’d say it would easily make solidly over 400hp with a little more cam and an intake manifold upgrade.

Although....... none of that will be happening on this motor.

In the car, it won’t have the headers either.

It’s a .030 440 with cast pistons down the hole .110”.

Small Summit cam(214/224-112), stock rockers and pushrods.

Stealth heads that have had the guides checked and the seats bumped with a stone. Zero porting.

Using all the hardware that came on the heads.

Stock 440 intake(casting number 3512501), 1” open carb spacer and an old 3310(750vs)carb, Hooker 1-7/8” headers.

Mopar ignition kit, timing 10* at idle/38* total.

CR works out to 8.7:1.

I’d say it would easily make solidly over 400hp with a little more cam and an intake manifold upgrade.

Although....... none of that will be happening on this motor.

In the car, it won’t have the headers either.

Last edited: