There’s a big factor!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2.76 open to 3.55 Sure Grip...expectations too high?

- Thread starter Righty Tighty

- Start date

-

Boy do I wish I knew all this when I had the engine out!! I’d love to swap converters now, but I’m not sure it’s worth the trouble at this point in time. That’s great information, it’s helping me understand the concept behind torque multiplication.The 1973 318s were advertised at 8.0 Scr, but generally. come in around 7.8 after a reman. The closed-chambers will bump that up, but I think 8.3 is about where yours might be. At 2700ft elevation, that's gonna hurt the bottom end power. The Wallace calculator predicts about 124 psi cranking cylinder pressure.

I had a freshened 1973 smogger , that I used to use as my winter engine, stock long-block, with a small-port intake, a 4bbl,fresh-air,and headers. I put that engine in every winter 5 or 6 years running, and it never had the same trans or gears in it. But when it had a a 904, then it also had a 2800TC. and when it had the 2800, then it usually had 3.23s. And in that combo, she was a ripper. and here's why; Below is a 5.2 Magnum graph, so much more powerful than either of our engines. But look at the shape of the curve. At 1800, it shows about 270 ftlbs. Let's arbitrarily drop that to 70% for your combo; so 189. And your TC is gonna multiply that by say 1.6 at Zero mph, so 302. Now the trans has a first gear multiplier of 2.45, so now 741. With the rear at 2.76, then 2045 into the rear axles.

But with 3.55s then 2630. Checkmark that.

Lets up the TC to 2800

On the graph, that looks like 295 ftlbs. Again at 70%=207ftlbs. But this time I'll estimate 1.7 in the TC@zero mph, and still 2.45 low and back to the 2.76s; I get 2374 ftlbs. So now with the TC alone, you are half way between 2.76 and 3.55, as compared to the 1700 stall. With 3.55s, this combos to 3054! and now 49% greater than where we started.

Ok but I know you're thinking, that don't sound like all that much,right? Well hang on; 189ftlbs at 1700rpm is 61hp. Whereas 207 at 2800 is 110hp, using the estimated numbers, this is an increase of 80% in horsepower.

Ok now I'm not saying the 2800TC will increase your delivered power to 110hp@2800. I'm saying you could be looking at a power increase of 80%@zero mph, over an 1800TC. And that is a really big deal. You understand the difference?

This is the bandaid for the low cylinder pressure.

View attachment 1715673960

I know elevation plays a critical role, but I guess I didn’t think that 2700 ft was that big of a deal!

what is your tire size?

My rears are 265 I wanna say?? So about 30 inches. I’ll double check tomorrow.

ir3333

Well-Known Member

There's your problem.Get a pair of 26" tires for the back.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,851

- Reaction score

- 12,201

The tallest tires you can put in an A-body are about 28

265s are NOT 30 inches, unless you are talking 265/75-15 truck tires

265s are NOT 30 inches, unless you are talking 265/75-15 truck tires

My mistake. I’ll check tomorrow when I’m home.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,851

- Reaction score

- 12,201

IMO: It absolutely will be worth it.but I’m not sure it’s worth the trouble at this point in time.

Another thing that will perk your combo up is more cylinder pressure. But to do some math, we kindof need to know what your current pressure is, so we can know how much room is in the combo.

But we can fool around with the math.

IIRC you said your cam is 256/262/112. For my calcs I will assume it is in at +4 or 4* advanced, so in at 108*.

And it's a reman 318LA, so say 3.93x3.315

And I;m gonna estimate an Scr of 8.3

And Wiki says you are at 2700ft. That is a big deal because compared to sealevel, your pressure will be down about 14psi

Ok so plugging all those numbers in to the Wallace Calculator I get;

Ica of 56*,and 2700ft

Static compression ratio of 8.3:1.

Effective stroke is 2.74 inches.

Your dynamic compression ratio is 7.03:1 .

Your dynamic cranking pressure is 123.98 PSI.

V/P (Volume to Pressure Index) is 99 .

The numbers of importance are;

Dcr of 7.03, and V/P of 99

The Dcr number for iron heads needs to be closer to 8.0 for maximum low rpm torque.

Read about VP here V/P Index Calculation

The VP number needs to be about 114, just to match a regular low-compression 318 at say 800ft elevation. But the fun don't start until over 130.

Now;

on the street, power don't mean a whole lot

Having the right power at the right time is what it IS about. I like the power to be right healthy at 30/35 mph, so that when I floor it, the dang thing takes off hard.

The 904 comes with ratios of 2.45-1.45-1.00

And your rear is a 3.55,

and your tires in a Valiant, like your Avatar, have to be more like 265/55-15s max, which come in around 26.5.. which times pi (3.1416) = a roll-out of 83.25. So then, the math is ;

rpm= (mph x1056x all the gears) / tire roll-out, and thus

rpm for 32mph, is 32 x1056x2.45x3.55/ 83.25=3530 at zero slip.

The 1-2 split is 1.45/2.45=.592 so in second gear, 32 mph will be 3530 x.592=2090. Assuming 8% slip cruising in Second, your tach might br reading 2260, that sounds pretty good so far.

At 32 mph; when the trans downshifts into First the slip might be 30%,I'm guessing, so the tach might read 3530 x1.3=4590. Now that's a lil high for your 262advertized cam, which doesn't have a lot of headroom there. But at 4590 it should move out real hard.

I'm gonna guess that 262 cam might be about 216@.050, and the power-peak on that might be 4900. With your heads, it might carry that out say 200rpm, and say 500 out, the power is crashing, so let's call the shift point to be 5400. In first gear, that is ~37.7mph. So as you can see, your 3.55s are a lil steep, for a downshift at 32 mph, because in the blink of an eye, just 6 mph higher, it will be time to shift.

So let's start over and work the numbers backwards.

For a power peak of 4900, the torque peak will be about 3400, so at what mph does this occur in first gear? At 30% slip again, my math says ~24mph. So 24mph is on the torque peak, so about the minimum roadspeed to floor it at, for good acceleration. Now we have 3 data points; 24 the minimum, 37.7 is time to shift, and 32 mph is a lil high. Lets try 26mph, and I get 3730 still at 30% slip. Ok so there you go; for your combo, slamming the pedal down at 26mph, should get you RapidTransit in First gear@3730rpm; and you won't have to shift until 5400/37.7mph.

So what happens at the shift into Second at 37.7 mph? Well the rpm drops to 59% or~3190. Now yur in trouble. Your low-pressure engine, with no help from the TC, is quite a bit off the cam, so it will struggle to get back up on it. 3400 in Second doesn't come until 44.3mph, so you will have a hole in performance between 37.7 and 44.3 mph, before the engine starts waking yo again. But, in second gear, the power peak of 4900 doesn't come around again until 62mph, and 5200 is 66.4

So, actually that cam is finishing well. I mean you could go down one size and not miss it, cuz now the cam would be done at 60ish.

How about passing gear?

Say you are motoring along at 60= ~2800, and you need to pass someone doing 55. So from 55=2570 you hit it. The trans downshifts into second, and the Rs climb to 55=4300 and you are away. Second will get you up to 69 mph/5400. He that's pretty good...

So as can be seen, the combo of the 256/262 cam and 3.55s are doing pretty good for you. The only problems are the lack of giddy-up off the starting pad, and the hole from 37.7 to 44.3 . The starting pad you can solve with stall, but stall cannot help with the hole. The hole can only be solved with more cylinder pressure.

In a given engine, there are about three ways to get more pressure;

1) taller pistons, or

2) machining the heads or decks, or installing a thinner head gasket.or

3) an earlier closing intake valve.

Of the three, a new cam is probably the cheapest.

The numbers above say that you can drop one size at .050. But the you really need a bigger change than that. So a swap to a solid lifter is the way to go. In your case; swapping the 216@.050 to say 208, while simultaneousy swapping to a solid, could get your advertised down 2 sizes, now yur talking.

Lets say you found a 208*@.050 after lashing cam, and say after lashing the advertised was 248, Lets say 248/256/108+2,SFT , that will set up with an Ica of 50*

and I get;

Ica of 50*/2700ft

Static compression ratio of 8.3:1.

Effective stroke is 2.86 inches.

Your dynamic compression ratio is 7.30:1 .

Your dynamic cranking pressure is 130.93 PSI.

V/P (Volume to Pressure Index) is 109

Well it's better but not really what I'm after. And not a big enough difference to spend all that money on.

Lets put some hi-compression pistons in there and get them up to Zero-deck, whatever it takes.

So we're gonna go from an estimated 90cc total chambers to an estimated 77cc, which will give you an Scr of 9.6.. And we'll leave your current cam in there.

Ica of 56*/2700 ft

Static compression ratio of 9.6:1.

Effective stroke is 2.74 inches.

Your dynamic compression ratio is 8.11:1 .

Your dynamic cranking pressure is 152.11 PSI.

V/P (Volume to Pressure Index) is 121

BadaBoom!, your Dcr is now up, your Pressure is up, and your Vp is approaching 5.2M status(124)

With "closed" chamber 302s your Quench is now whatever your gasket is, so yo actually have room for a lil more pressure. But 152psi will still burn 87 gas. This is what I was looking for.

It ain't great, but at 2700 ft, it can't get much better.

Since the engine would have to be out for this, I would combine this with a 2800TC..

Now I suppose it is possible that the pistons currently in the engine are already closer to the decks, then the mediocre heights of the stockers, so that would open up other possibilities of pumping up the pressure. The key in my calcs was the 77CC total chamber volume;there are lots of ways to get to there; It doesn't have to be pistons. But I just like to spend my money on things I can touch,lol. I am not fond of machining everything in sight. Too often it ends up screwing with the intake fitment. And it always leads to new pushrods.

Remember I am just fooling around with the math here, killing time until we see more of your combo.

Happy hotRoddingi

Thanks AJ, that's all very good info. It's fascinating to look at the numbers and how they affect engine performance, not just arbitrarily bolting on fancy looking parts and hoping for the best. Lemme tell you how much those numbers make me want to pull the engine and do some work, but man, after having it out for so long, it's nice just to be able to turn the key and drive it. Even if it's NOT a race car! Plus I'm catching up on projects around the house that were put on hold while the engine was being rebuilt.

I should've mentioned also that my cylinders are .040 over, and the pistons I have are the Sealed Power H814CP. I've never checked engine compression and I don't have a tester, so it might be a day or two until I can get that done and report back.

My tires are another story, I'm shamefully ignorant with the metric tire sizes, mostly because I'm too lazy to learn about what means what. I do know that I went with a 15" wheel in the back, and a slightly taller tire. I'm working today and won't be home until tomorrow, so again that's something that will have to wait until I can get outside and look.

I should've mentioned also that my cylinders are .040 over, and the pistons I have are the Sealed Power H814CP. I've never checked engine compression and I don't have a tester, so it might be a day or two until I can get that done and report back.

My tires are another story, I'm shamefully ignorant with the metric tire sizes, mostly because I'm too lazy to learn about what means what. I do know that I went with a 15" wheel in the back, and a slightly taller tire. I'm working today and won't be home until tomorrow, so again that's something that will have to wait until I can get outside and look.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,851

- Reaction score

- 12,201

Also, when you get home, See if you can get the exact cam specs, cuz 256@.050 is seriously radical, and not what's in your engine. I mean I doubt that your builder would stick you with something like that. And you wouldda said something as to how radical it was.

But 256 advertized is entirely doable

But 256 advertized is entirely doable

Well, my builder is yours truly haha, but I did get all (okay most) of my advice on the specifics from FABO. I'll pull out the cam card and see what it says, and I think maybe I assumed all the specs for cams mean @ .050.

Actually, I just looked up the specs on the Lunati site and here they are:

It's the Voodoo 701

Advertised Duration (Int/Exh): 256/262; Duration @ .050 (Int/Exh): 213/220; Gross Valve Lift (Int/Exh): .454/.475; LSA/ICL: 112/108; Valve Lash (Int/Exh): Hyd/Hyd; RPM Range: 1000-5500

As you can see, I was mistaken. 256 advertised and 213 @ .050.

Actually, I just looked up the specs on the Lunati site and here they are:

It's the Voodoo 701

Advertised Duration (Int/Exh): 256/262; Duration @ .050 (Int/Exh): 213/220; Gross Valve Lift (Int/Exh): .454/.475; LSA/ICL: 112/108; Valve Lash (Int/Exh): Hyd/Hyd; RPM Range: 1000-5500

As you can see, I was mistaken. 256 advertised and 213 @ .050.

thesiren74

Well-Known Member

Go from a stock stall to 3,500 stall and you'll feel and see the difference.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,851

- Reaction score

- 12,201

Those pistons are listed as flat-top hypers with no valve reliefs and a compression distance of 1.755. In a 9.600 318, that maths to being down in the hole .064, which at 3.950 bore is 12.95cc. the gasket is gonna be between 6.3 and 8.6cc. And unmilled 302 heads might be 65cc, so that totals 86.75cc, hey that ain't so bad.... with a 9.95 bore your swept is 665.68, making your Scr to be ~8.67.... but this assumes a 9.600 deck.

With the new numbers, The Wallace predicts ~132 psi, and the new V/P is 106, better than 99, but still pretty weak. We'll see how your Compression test compares.

With the new numbers, The Wallace predicts ~132 psi, and the new V/P is 106, better than 99, but still pretty weak. We'll see how your Compression test compares.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,851

- Reaction score

- 12,201

That Lunati 701 is a nice cam, slightly faster than I estimated.

You couldda done a lot worse,lol.

You couldda done a lot worse,lol.

Okay, my rear tires are 245/60R15, which works out to 26.6". I'm gonna get after doing a compression test later today and will report back the results.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,851

- Reaction score

- 12,201

So far I'm doing pretty good; I got the tires right on, but overstated the intake duration @.050 by 3 degrees, which will not affect the Ica; So all my calcs are spot on. I even called the shift rpm within 100rpm. So, on a roll;Okay, my rear tires are 245/60R15, which works out to 26.6". I'm gonna get after doing a compression test later today and will report back the results.

you wanna hear about my Theory of the Enclosed Earth System? Go to; AJ's Opinion; the shape of the Earth in the Search bar..

https://www.forabodiesonly.com/mopa...he-shape-of-the-earth.480916/#post-1973272310

ir3333

Well-Known Member

OK...it's not your 30" tires!Okay, my rear tires are 245/60R15, which works out to 26.6". I'm gonna get after doing a compression test later today and will report back the results.

So far I'm doing pretty good; I got the tires right on, but overstated the intake duration @.050 by 3 degrees, which will not affect the Ica; So all my calcs are spot on. I even called the shift rpm within 100rpm. So, on a roll;

you wanna hear about my Theory of the Enclosed Earth System? Go to; AJ's Opinion; the shape of the Earth in the Search bar..

https://www.forabodiesonly.com/mopa...he-shape-of-the-earth.480916/#post-1973272310

I was going to comment on how closely you nailed the shifting in post #31, because punching it in 1st around 25mph gets some good response, then mediocre performance until I hit higher speeds.

I also think I'm not allowed to visit whatever forum you've posted that in.

OK...it's not your 30" tires!

Yeah! 30 inches seemed pretty tall since I have 33s on my truck, but my ignorance in knowing metric tire sizes and not being with the car to double check the size led me down that path.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,851

- Reaction score

- 12,201

There you go!I was going to comment on how closely you nailed the shifting in post #31, because punching it in 1st around 25mph gets some good response, then mediocre performance until I hit higher speeds.

The only cure for that hole, long after stall, is more pressure, as described in the post. Or.... closer spaced gearing; like a 4 speed; which will prevent the rpm from dropping so far, and, since your average power in each selected gear will be higher, that points to quicker thru the gears. So there is another option, but pressure is better and probably less money too.

The higher stall, streetable stall, only helps you get off the line, and if you happen to downshift into a sub-stall rpm. Once you are accelerating past stall rpm, it'd pretty much all on the motor. The stator is still giving you something, but the shape of your power-curve remains the same, and if there is a hole in the power delivery, that will not go away.

But you can change the size of the hole.

With say a 2000 stall, and the start of the powercurve being say 3400, that is a mighty big 1400rpm hole.

With a 2800TC the hole is reduced to 600rpm.

With a 3400TC, the hole goes away.

Same goes for the A833 4-speed, with average drops to 72.5%. Shifting at 5200 The Rs drop to 3770, hole G-o-n-e.

pishta

I know I'm right....

I broke a 3.55 7.25 SG friday night  and had to replace with a 2.76 open to get to school on Monday :-( ...went from a rocket off the line to a freight train on the freeway, with as much acceleration......neutered!

and had to replace with a 2.76 open to get to school on Monday :-( ...went from a rocket off the line to a freight train on the freeway, with as much acceleration......neutered!

pishta

I know I'm right....

A 318 with 230 HP...just like they called out in 1967!

67Dart273

Well-Known Member

If you don't notice night and day, it wasn't running right to begin with.

I'm goin' with this right here

Uh oh....I started on cylinder 1 and got about 140psi. Number 2, about 100. I don’t necessarily trust this gauge since I bought it second hand a couple years ago, so I’m going to check it against a new, quality gauge. We shall see what the other cylinders have to say about this...

It's funny, I saw an 833 for sale last night and started researching what it would take for the conversion. After all, I really do prefer manual vehicles - last 20 years that's all I've had. But, it's a little more money and effort I'm willing to invest at this point, especially since there are so many other points that need to be dialed with this car. I don't want to complicate things even further.There you go!

The only cure for that hole, long after stall, is more pressure, as described in the post. Or.... closer spaced gearing; like a 4 speed; which will prevent the rpm from dropping so far, and, since your average power in each selected gear will be higher, that points to quicker thru the gears. So there is another option, but pressure is better and probably less money too.

The higher stall, streetable stall, only helps you get off the line, and if you happen to downshift into a sub-stall rpm. Once you are accelerating past stall rpm, it'd pretty much all on the motor. The stator is still giving you something, but the shape of your power-curve remains the same, and if there is a hole in the power delivery, that will not go away.

But you can change the size of the hole.

With say a 2000 stall, and the start of the powercurve being say 3400, that is a mighty big 1400rpm hole.

With a 2800TC the hole is reduced to 600rpm.

With a 3400TC, the hole goes away.

Same goes for the A833 4-speed, with average drops to 72.5%. Shifting at 5200 The Rs drop to 3770, hole G-o-n-e.

Sorry for your loss...haha.I broke a 3.55 7.25 SG friday nightand had to replace with a 2.76 open to get to school on Monday :-( ...went from a rocket off the line to a freight train on the freeway, with as much acceleration......neutered!

If this is the case, I hope I can figure it out. I will say that the car IS faster. Definitely. With the 2.76s it really didn't even want to spin one wheel, now with the 3.55's it'll smoke both tires. However I'm getting some wheel hop and I'd like to get these weak springs off the car before going too far.I'm goin' with this right here

I tested cylinder compression with a new, good gauge and here are the results. I tested each cylinder twice, with the exception of #7 since it was low on the first two.

CYLINDER

1 - 130, 133

2 - 135, 134

3 - 131, 129

4 - 134, 133

5 - 136, 136

6 - 140, 139

7 - 122, 122, 120

8 - 137, 137

Now, with 7 being that much lower than the rest, I have a couple questions. What could cause this? Bad rings? Could this difference cause performance issues? How can I diagnose and solve the lower compression, and is that even enough of a difference to worry about?

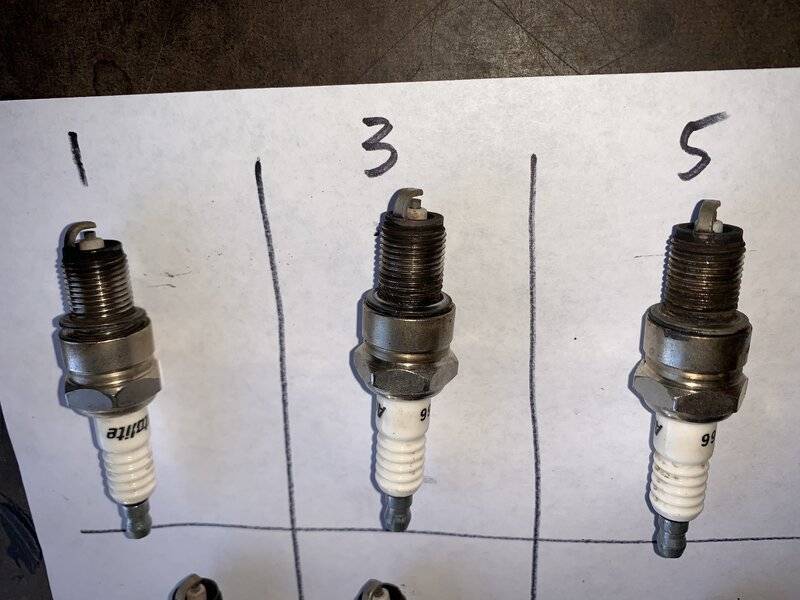

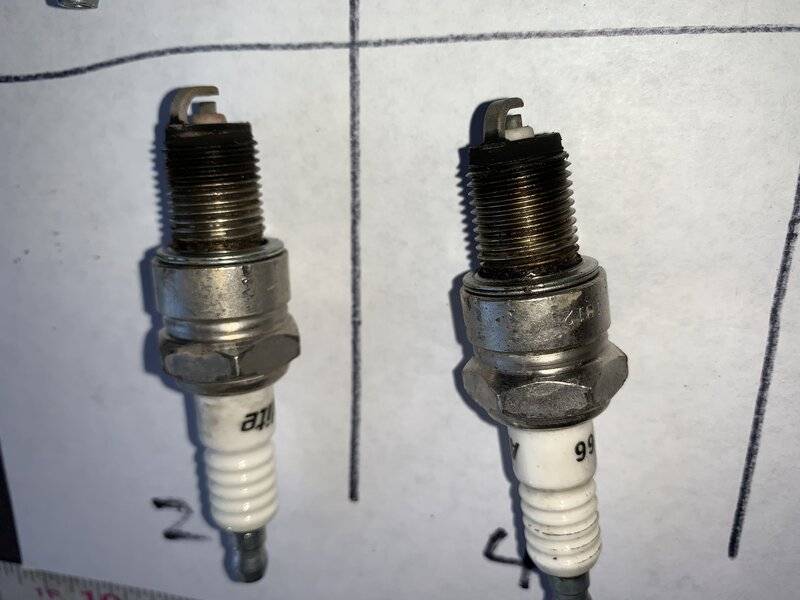

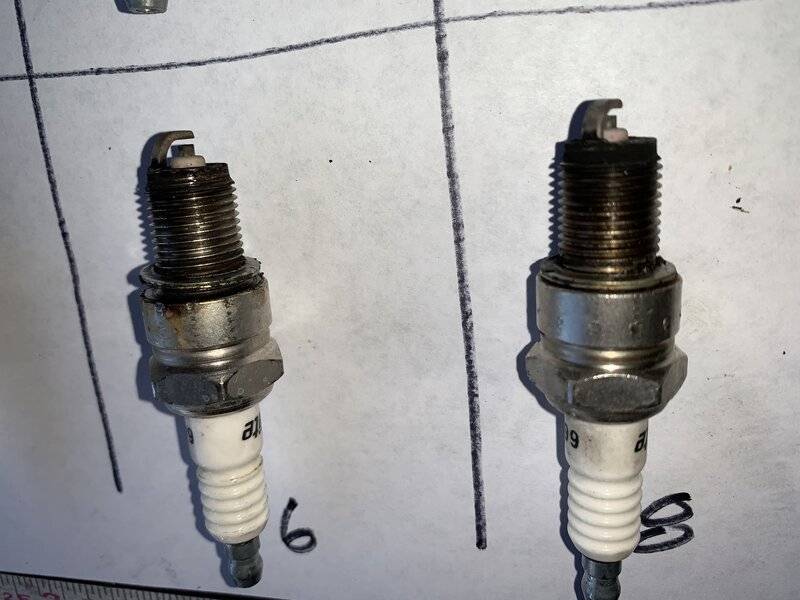

Forgot that I took pictures also of the plugs. They all seemed pretty uniform, except for #7, which had just a tiny bit more soot on the ground strap.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,851

- Reaction score

- 12,201

With the new numbers, The Wallace predicts ~132 psi, and the new V/P is 106, better than 99, but still pretty weak. We'll see how your Compression test compares.

Average 1331 - 130, 133

2 - 135, 134

3 - 131, 129

4 - 134, 133

5 - 136, 136

6 - 140, 139

7 - 122, 122, 120

8 - 137, 137

I'd say the Wallace is right on target

And I'd say there's your low-rpm power problem.

Now, what to do about it.....

#7 cylinder is ~10% down from the average, but #6/8 are 5% higher. So Ima thinking you need to do a LeakDown test, cuz something is goin' on in there, in it can't be good. That is what I would do.

Looking at the plugs, what Timings are you running? Looks a hair lean to me, and a hair hot.

@yellow rose ?

Last edited:

ir3333

Well-Known Member

i wouldn't worry about it.Plugs look good and it'll probably last a long time!

-