There IS NO power to the distributor. The distributor generates power via the pickup coil and magnets. You should be able to put your meter on low AC volts and connect to the dist. pickup, spin the shaft or crank the engine and it should generate about 1V AC. Those connectors can be trouble as there is no real current there, so ANY corrosion will stop the trigger signal. Examine the connector with a light for corrosion, and work it in/ out several times to "feel" for tightness and to scrub the terminals.

Turn the key to 'run.' Separate the dist connector and take hold of the engine harness end. "Rig" a test gap or plug to the coil tower. Touch the bare terminal of the connector repeatedly to engine ground. You should get one single "SNAP" spark each time

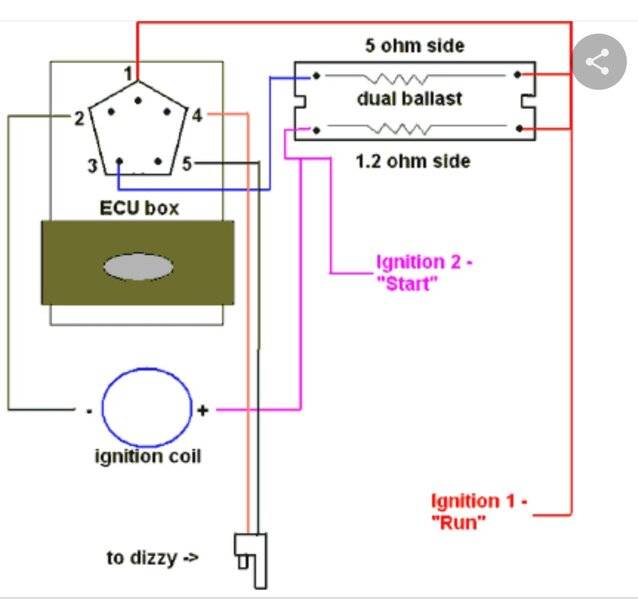

Reconnect. Rig your meter to coil+ and ground. You should get full battery voltage at the coil when cranking. When key is in "run" coil should read, say, 6-10V. Not more. Full 12V in "run" indicates coil is not drawing current

ECU MUST MUST be grounded.