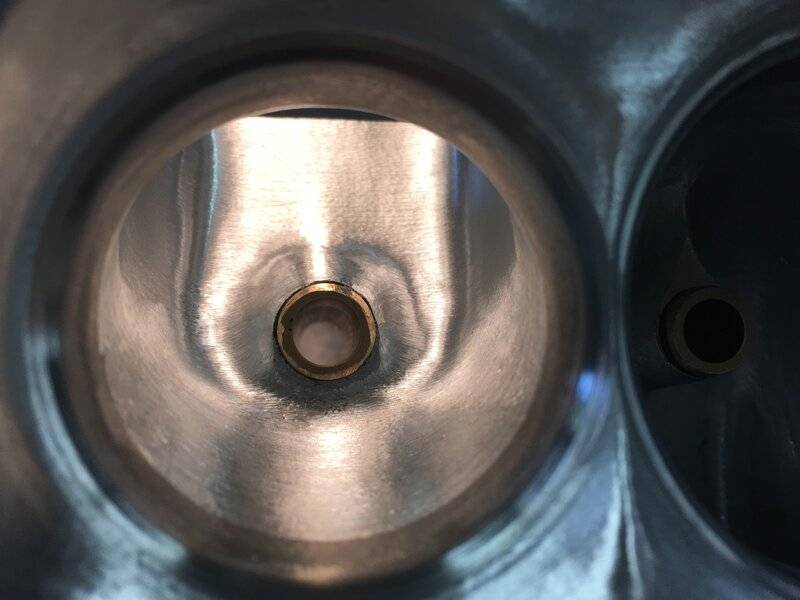

Speedmaster intake porting. Hopefully I can make something out of this

I rarely end up with troughs that need to be worked out........ and I find it’s easier to get them leveled out with coarser burrs as opposed to finer.

For aluminum heads, I use the non-ferrous burrs to get the porting roughed in........ then I’m just diminishing the surface roughness by using progressively less coarse burrs.

And then all I’m doing on the jobs that are getting the sanding roll’s is smoothing out the finish.

I try and do all the shaping with the burrs.

About the only place I might use a sanding roll for final shaping is the SSR.

It’s like most “skills”...... it takes practice to get good at it.

I rarely end up with troughs that need to be worked out........ and I find it’s easier to get them leveled out with coarser burrs as opposed to finer.

For aluminum heads, I use the non-ferrous burrs to get the porting roughed in........ then I’m just diminishing the surface roughness by using progressively less coarse burrs.

And then all I’m doing on the jobs that are getting the sanding roll’s is smoothing out the finish.

I try and do all the shaping with the burrs.

About the only place I might use a sanding roll for final shaping is the SSR.

It’s like most “skills”...... it takes practice to get good at it.