Yep, it made sense in my nugget for turns and such. With dividing ports I had thought of it more like a boat cutting through water, figures 20 years in the Navy! LolIt’s been noted before air and fuel do not seem to like sharp, corners, dividing walls, turns, etc....

There are some interesting videos and notations in books in this. Seems weird though right?! It just goes to show that not everything is working with your logic. I guess that is what makes science so cool. You never know until you know.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Speedmaster intake porting. Hopefully I can make something out of this

- Thread starter pittsburghracer

- Start date

-

yellow rose

Overnight Sensation

Yaaa I had some time in this one and can’t wait to really put it to the test. I’m not a believer in sharp edges. I guess I always keep a picture of airplane wings in my head. Nice and rounded on the leading side thinning down on the rear. Needing volume and access to the air you really can’t use this principle to a tee but I sure like radius’s.

Yep. Sometimes you have to compromise on a shape (yes...it’s all about shape) to get size and taper.

My SD has pretty sharp dividers in it so I could get the taper I wanted. It was a compromise.

Trying to do some research on why the LD340 intake is so much better than the Speedmaster and looking at pictures of both it’s pretty obvious. Looking at the runner size and shape they copied the Edelbrock RPM and must have used LD4B port sizing. I gotta get moving on my 408 for the 2021

race season but I gotta try a few things first. I can send this thing to him with a good set of heads and losing 50-60cfm with this intake. Look at the runners in front of the carb pad on both these intakes

race season but I gotta try a few things first. I can send this thing to him with a good set of heads and losing 50-60cfm with this intake. Look at the runners in front of the carb pad on both these intakes

gregcon

Well-Known Member

- Joined

- Dec 20, 2009

- Messages

- 735

- Reaction score

- 816

Decades back, I was running a Torker on my 440. I'd spin it to 6600RPM every weekend at the track.

I kept reading magazines that without exception extolled the virtues of the dual plane intake. Only an idiot would run anything else. So, I ordered a new Edelbrock Performer and swapped it out. The next day, I drove it to the track and that was one of the few days I left early....the engine would get to about 5000RPM then nose dive. Kinda like what it feels like when you run on down a concrete sidewalk then transition to sand. The Torker went back on, and 6600RPM came back.

I kept reading magazines that without exception extolled the virtues of the dual plane intake. Only an idiot would run anything else. So, I ordered a new Edelbrock Performer and swapped it out. The next day, I drove it to the track and that was one of the few days I left early....the engine would get to about 5000RPM then nose dive. Kinda like what it feels like when you run on down a concrete sidewalk then transition to sand. The Torker went back on, and 6600RPM came back.

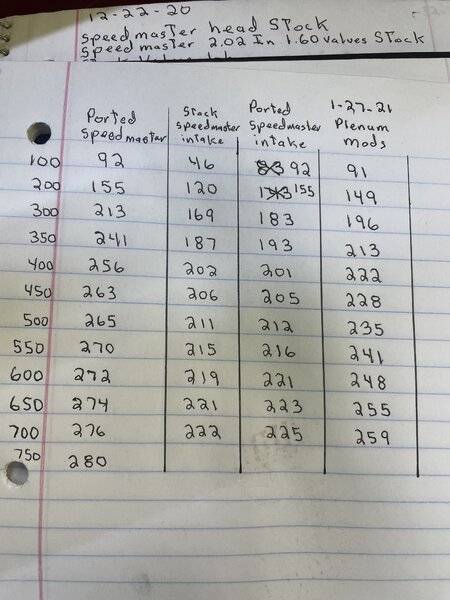

Ok a couple days of thinking and planning paid off. This mod was to the plenum only and required some time and grinding to accomplish. During the process you are basically improving two runners at the same time. I did grind through to another runner so I have a pretty easy repair ahead of me when I have my welder set up for aluminum. Now I know where to stop on the other side. I know what it needs for further progress but being Ethan is running a smaller cam and I would never run this intake it would be time wasted. I will let the cat out of the bag on this mod at a later date after I can explain how to safely do it. Today’s flow numbers are all on the same runner to show improvements in flow

Enjoying this. I have 3 of these SM intakes...Ok a couple days of thinking and planning paid off. This mod was to the plenum only and required some time and grinding to accomplish. During the process you are basically improving two runners at the same time. I did grind through to another runner so I have a pretty easy repair ahead of me when I have my welder set up for aluminum. Now I know where to stop on the other side. I know what it needs for further progress but being Ethan is running a smaller cam and I would never run this intake it would be time wasted. I will let the cat out of the bag on this mod at a later date after I can explain how to safely do it. Today’s flow numbers are all on the same runner to show improvements in flowView attachment 1715678959

Enjoying this. I have 3 of these SM intakes...

As you can see that sucker could make some nice horsepower now with the right cam.

Yes, some potential for sure... Lookin forward to the plenum modsAs you can see that sucker could make some nice horsepower now with the right cam.

Yes, some potential for sure... Lookin forward to the plenum mods

For now think radius’s not right 90 degree angles. Run you finger at the bottom of the plenum.

yellow rose

Overnight Sensation

For now think radius’s not right 90 degree angles. Run you finger at the bottom of the plenum.

LOL...easier said than done...

PBR , I'm really looking forward to seeing some shots of your plenum mods. I carved up the top of an LD4B a few years ago in anticipation of using a spacer and assuming the air colliding with the flat shelf at the divider would cause turbulence. I don't have a bench and don't know what I'm doing.

As you can see that sucker could make some nice horsepower now with the right cam.

How do you think the ported speedmaster would compare with an as cast performer rpm inlet?

How do you think the ported speedmaster would compare with an as cast performer rpm inlet?

I never flowed one but honestly I don’t think it could stack up against this intake now. But it was a lot of work getting there.

What if you could get one sent to you? Would you have the time to flow test the as cast RPM AG on the head?I never flowed one but honestly I don’t think it could stack up against this intake now. But it was a lot of work getting there.

What if you could get one sent to you? Would you have the time to flow test the as cast RPM AG on the head?

If a had one sitting hear I would gladly do it but at this stage I think it would be wasted time. Who in their right mind would pay or port a set of small block heads to the 280cfm area and throw an out of the box (especially dual plane) intake on it. I gotta get this intake finished, flow the exhaust side of the head, and move on to race stuff. I know Hughs did some flow testing with that intake but they may have flowed the intake by itself. I may make up an adapter to try this out of some lexan I have here just for curiosity.

yellow rose

Overnight Sensation

If a had one sitting hear I would gladly do it but at this stage I think it would be wasted time. Who in their right mind would pay or port a set of small block heads to the 280cfm area and throw an out of the box (especially dual plane) intake on it. I gotta get this intake finished, flow the exhaust side of the head, and move on to race stuff. I know Hughs did some flow testing with that intake but they may have flowed the intake by itself. I may make up an adapter to try this out of some lexan I have here just for curiosity.

If I had a dollar for every unported intake on ported heads I could pay off my house.

Anything more than a gasket match is all most customers want. Quote them 750 bucks to fix their intake and watch them lose their ****.

They say “it was 1500 bucks to port the heads and that’s with a valve job and surface and you want HALF that to port the intake?????? Sounds crooked to me...sounds like you want to make money on the intake you didn’t charge me for on the heads...there ain’t no way I’ll get 750 bucks worth of performance out of that... and many more things like that have been said to me for telling them I don’t port heads and not the intake.

My rough measurements say most single 4 intakes have a runner length 200% longer than the port in the head. That means you have all that extra surface area to shape and finish.

Guys just don’t get it.

I see my super Victor and 1250 dominator have quite the mismatch. The Reher and Morrison spacer plate is so the blades can open all the way. I know the pics aren’t the best but u get the jist of it. Kim

If I had a dollar for every unported intake on ported heads I could pay off my house.

Anything more than a gasket match is all most customers want. Quote them 750 bucks to fix their intake and watch them lose their ****.

They say “it was 1500 bucks to port the heads and that’s with a valve job and surface and you want HALF that to port the intake?????? Sounds crooked to me...sounds like you want to make money on the intake you didn’t charge me for on the heads...there ain’t no way I’ll get 750 bucks worth of performance out of that... and many more things like that have been said to me for telling them I don’t port heads and not the intake.

My rough measurements say most single 4 intakes have a runner length 200% longer than the port in the head. That means you have all that extra surface area to shape and finish.

Guys just don’t get it.

I never charged over 750.00 for heads and intake (including valve job and flow testing at least before and after) but that’s probably why I quit porting heads for customers. The final stray was seeing a casting crack on a set of small block Ford heads on the floor. It ended up being nothing but still had to be magnifluxed. I had a lot of satisfied customers and still get calls and requests but I’m to slow to make any money doing this stuff. I wish my son had an interest in learning how to do this crap as he could use the extra money. He an on the road mechanic fixing fork trucks so he has mechanical abilities. Ohhhhh well.

I see my super Victor and 1250 dominator have quite the mismatch. The Reher and Morrison spacer plate is so the blades can open all the way. I know the pics aren’t the best but u get the jist of it. Kim

View attachment 1715679342

View attachment 1715679343

View attachment 1715679344

View attachment 1715679345

Oh ya you have some work ahead of you.

yellow rose

Overnight Sensation

I never charged over 750.00 for heads and intake (including valve job and flow testing at least before and after) but that’s probably why I quit porting heads for customers. The final stray was seeing a casting crack on a set of small block Ford heads on the floor. It ended up being nothing but still had to be magnifluxed. I had a lot of satisfied customers and still get calls and requests but I’m to slow to make any money doing this stuff. I wish my son had an interest in learning how to do this crap as he could use the extra money. He an on the road mechanic fixing fork trucks so he has mechanical abilities. Ohhhhh well.

LOL...you work too cheap. When the shop rate is 100 bucks an hour and that is just working for wages because you’re lucking if you get paid for 75% of your billable hours.

That’s how you go broke.

Of course, working from a home shop reduces the hourly rate. When you add up paper rolls, burrs, wax, ATF or WD-40, wear on the grinder, running the lights and compressor, cleaning the crap up when you are done, gloves, laundry...I’m forgetting some stuff...cleaning chemicals...it all adds up.

My wife has about 60 hours in one report. She will make about 7 dollars an hour when she gets paid. I’ve told her you can’t write a 335 page report for that kind of money. Lawyers don’t work that cheap. CPS doesn’t work that cheap. But it keeps her busy and happy so it is what it is.

I’m thinking my Indy SR heads may be the choke point at this time. So then will it be beneficial to port the intake at this point? Thanks. KimOh ya you have some work ahead of you.

TT5.9mag

Two atmospheres are better than one

@pittsburghracer spill the beans. Show us the plenum work you did. Kidding. Thanks for documenting this intake work.

yellow rose

Overnight Sensation

I’m thinking my Indy SR heads may be the choke point at this time. So then will it be beneficial to port the intake at this point? Thanks. Kim

YES!!!!! You’d have a choke point at the heads and the intake. I’m not sure that your heads are much of a choke either. But that intake needs serious work.

About 3 months ago I was looking at a manifold that was bolted to the flow bench. It was a dominator top but something just bothered me. I was talking and looking the intake over at the same time, and then it hit me.

Whoever made the intake (I can’t remember whose intake it was) just took a 4150 top and converted it to a 4500 top. It looked a lot like what your intake does, in that the outer edges of the throttle blades are opening right on top of the runners. On that intake, the opening from the flange to the top of the runner was a little more that a 120 degree bend!!!!!!

There were two options to fix it. One was put a 2 inch spacer on it and try and blend some of that out. That IMO was the best option.

The other option was to bring it home and weld up all for corners of the manifold where the flange met the runner. My rough guess was 4 hours of welding minimum. Then you have to machine and grind the plenum to get it right. I took a hard pass on that.

The guy ended up selling that intake and starting with a better piece. I’ll see if they actually did any flow tests on it, or if they just said screw it and took it off the bench.

I’d bet everything guy was having distribution issues like crazy, because he complained the car was sucky in the gear changes and off the foot brake. Plus other issues.

I don’t know who can produce and sell an intake like that. My guess was it was a very old intake that was made 20 plus years ago when everyone started switching to dominators and they reengineered an existing 4150 intake to take the 4500. It was straight garbage.

Idk how old it is. It was a trade deal that was good for both of us. This carb has 2 1/8 throttle blades. A 1050 and 1150 have 2 inch blades. I suppose a smaller carb may help but maybe not. I don’t want to be cutting, welding and grinding for a few extra horses. This engine is a 543 11-1 compression. .625 lift solid roller. Kim

yellow rose

Overnight Sensation

Idk how old it is. It was a trade deal that was good for both of us. This carb has 2 1/8 throttle blades. A 1050 and 1150 have 2 inch blades. I suppose a smaller carb may help but maybe not. I don’t want to be cutting, welding and grinding for a few extra horses. This engine is a 543 11-1 compression. .625 lift solid roller. Kim

It’s not always a horsepower thing. You may just be outside of measurable error on HP on a dyno, but in the car transient response may be huge. Any time you force air to change directions you lose energy. The tighter the change, the more loss.

The rule of thumb is no more than a 7 or 8 degree change. That means a standard 30/45/60 valve job is bending the air about double what the air will tolerate. Plus most of the cuts are under .100 wide so there isn’t a bunch of time for the air to bend.

That rule of thumb applies anywhere in the system. Add fuel to the air and the air doesn’t bend as well.

It’s all about shape. And some of it is not measurable on a water brake dyno.

-