chinze57

Push Button tranny and a Slant 6 that'll never die

Well, my new Slant 6 is in as of today.

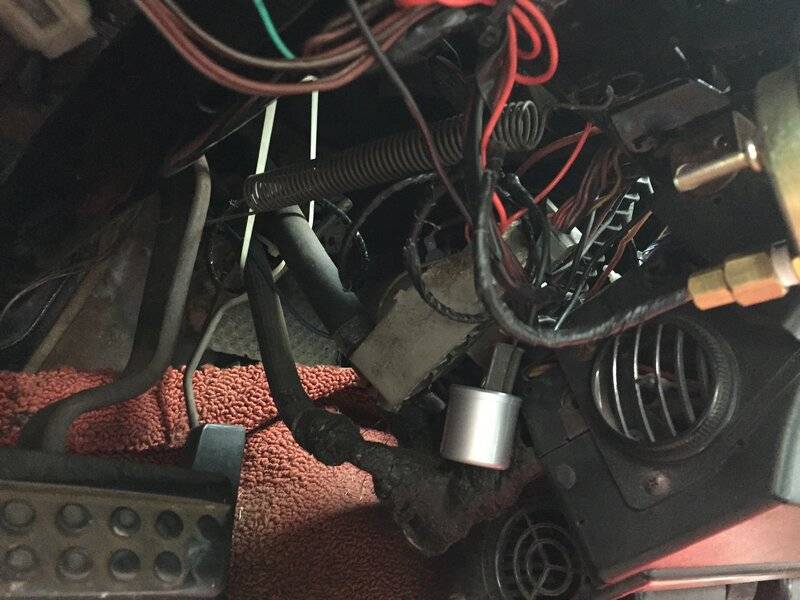

This is the photo my mechanic sent me after it went in.

This is the photo my mechanic sent me after it went in.

This has been a long 2.5 months. My rear main seal was shot, leaking a quart of oil every week and a half or so. Talked to a mechanic who did the initial work when I bought it to get it up to snuff, and he said “look at getting that engine rebuilt or you’re just going to keep throwing good money after bad”. So I did, talked to one of my coworkers who’s a car guy and lo and behold his dad has a shop and they only work on classics. What luck.

Went to the shop and talked to him, he’d never worked on a /6 before and was excited to do it, so a couple days later I dropped it off. After he pulled the engine, we discovered it was not a 225 as we had thought, but a 170. Ok, that’s too bad, but c’est la vie. He took some measurements and it had been bored .060” over already. The pistons had been knurled. Not great. We talk options, and he found a 225 in a 69 dart a couple hours away, seller only wanted $170 for it.

He went and got it and stripped it down to take it to the machine shop and found it was in fact a 225, but was not originally from the 69 dart it had come from, but from a 77, we think probably an aspen.

So he takes it to the machine shop, they measure it, and it’s practically perfect. No work had been done to it, everything was still well in line, we could have just cleaned it and put it back together and called it a day.

But where’s the fun in that? So we decided to bore it .030” over, put in a new cam, and switched to mechanical rockers. We did run into the issue that the gasket set didn’t arrive until mid January. It was back ordered for a while. Did have an issue with the flex plate as another person in this forum did a couple weeks back too, so had to get that sorted.

Now that it’s in, planning on putting a 4bbl Holley on top and running headers with 2 or 2.25” exhaust with a cherry bomb.

While it was there he rewired the car using a Ron Francis kit, really excited that that’s done. The wiring was incredibly sketchy before, lots of splicing, fuse block was melted and had been mostly bypassed, some gauges non-functional, just a lot of bad.

But that’s fixed now.

Figured I’d post this to show y’all the new engine, I’ll post some more pics of the engine in various stages as well as the old engine bay below.

This has been a long 2.5 months. My rear main seal was shot, leaking a quart of oil every week and a half or so. Talked to a mechanic who did the initial work when I bought it to get it up to snuff, and he said “look at getting that engine rebuilt or you’re just going to keep throwing good money after bad”. So I did, talked to one of my coworkers who’s a car guy and lo and behold his dad has a shop and they only work on classics. What luck.

Went to the shop and talked to him, he’d never worked on a /6 before and was excited to do it, so a couple days later I dropped it off. After he pulled the engine, we discovered it was not a 225 as we had thought, but a 170. Ok, that’s too bad, but c’est la vie. He took some measurements and it had been bored .060” over already. The pistons had been knurled. Not great. We talk options, and he found a 225 in a 69 dart a couple hours away, seller only wanted $170 for it.

He went and got it and stripped it down to take it to the machine shop and found it was in fact a 225, but was not originally from the 69 dart it had come from, but from a 77, we think probably an aspen.

So he takes it to the machine shop, they measure it, and it’s practically perfect. No work had been done to it, everything was still well in line, we could have just cleaned it and put it back together and called it a day.

But where’s the fun in that? So we decided to bore it .030” over, put in a new cam, and switched to mechanical rockers. We did run into the issue that the gasket set didn’t arrive until mid January. It was back ordered for a while. Did have an issue with the flex plate as another person in this forum did a couple weeks back too, so had to get that sorted.

Now that it’s in, planning on putting a 4bbl Holley on top and running headers with 2 or 2.25” exhaust with a cherry bomb.

While it was there he rewired the car using a Ron Francis kit, really excited that that’s done. The wiring was incredibly sketchy before, lots of splicing, fuse block was melted and had been mostly bypassed, some gauges non-functional, just a lot of bad.

But that’s fixed now.

Figured I’d post this to show y’all the new engine, I’ll post some more pics of the engine in various stages as well as the old engine bay below.