RAMM

Well-Known Member

Well this is going to be interesting for me as I don't often get the chance to work on W9's.

The two P's in the title stand for P reviously P orted in case anyone was wondering.

I had a great customer and FABO member send me his W2's and he travels in a fairly serious circle of drag strip guys out his way, and next thing you know a guy he knows sends me these lightweight beauties to work on. The mandate is to find more power for the guy so that is what the focus is on. The car is drag 'Cuda with a hi-compression 416 on alcohol with a .700" roller so it doesn't really compromise on anything which should make my job a little simpler. I understand it already runs pretty deep into the 9's @ 135+mph so I really don't want to muck this up.

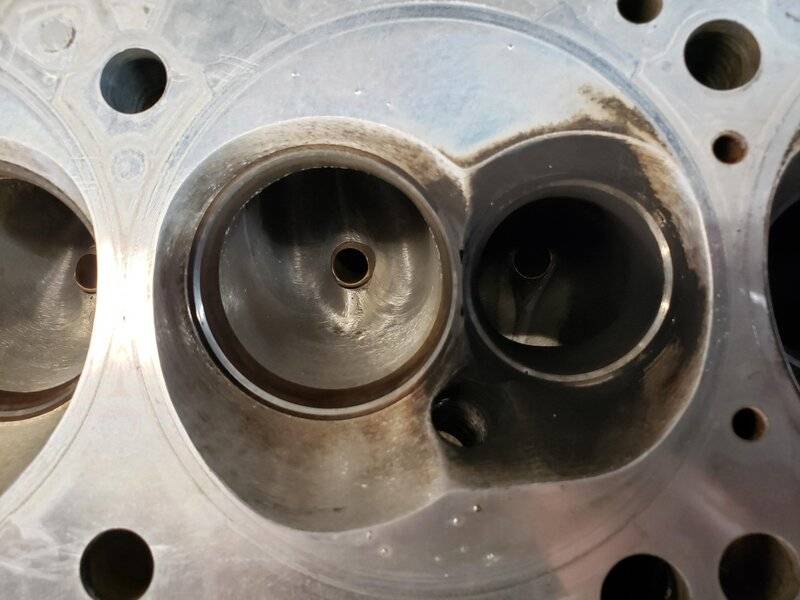

Initial inspection tells me that the port work looks pretty good. The intake valve combination is 2.15"/1.60" 3/8" stem which kinda surprised me--heavy @ 5.420-5.430 OAL. The throats measure right @ 90% -1.935" . The only thing I'm wondering is if the intake valve is a little too big for the 4.07" bore @ almost 53%. Usually anything over 51.5% or so on an inline begins to negatively impact power which is probably due to excessive shrouding, I guess.

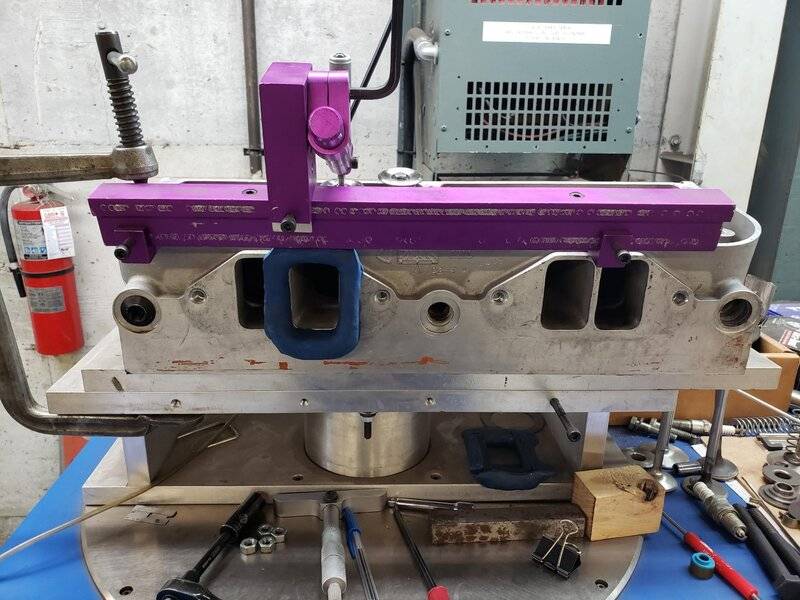

So after removing the springs which are pretty serious with 273lbs @ 2.00 704lbs @ 1.300" I washed em up and picked a port and flow tested it. On a 4.06" bore @ 28" H20 they went:

.100 66.5

.200 133

.300 189.1

.400 241.7

.500 287

.600 314.4

.700 327.5

.750 323.5

.800 315.5

They actually peaked @ 330.5 @ .735"

I thought this was pretty good to be honest and with his .700" SR cam it is probably accessing an awful lot of that 330 ish cfm. More to follow in a moment. J.Rob

The two P's in the title stand for P reviously P orted in case anyone was wondering.

I had a great customer and FABO member send me his W2's and he travels in a fairly serious circle of drag strip guys out his way, and next thing you know a guy he knows sends me these lightweight beauties to work on. The mandate is to find more power for the guy so that is what the focus is on. The car is drag 'Cuda with a hi-compression 416 on alcohol with a .700" roller so it doesn't really compromise on anything which should make my job a little simpler. I understand it already runs pretty deep into the 9's @ 135+mph so I really don't want to muck this up.

Initial inspection tells me that the port work looks pretty good. The intake valve combination is 2.15"/1.60" 3/8" stem which kinda surprised me--heavy @ 5.420-5.430 OAL. The throats measure right @ 90% -1.935" . The only thing I'm wondering is if the intake valve is a little too big for the 4.07" bore @ almost 53%. Usually anything over 51.5% or so on an inline begins to negatively impact power which is probably due to excessive shrouding, I guess.

So after removing the springs which are pretty serious with 273lbs @ 2.00 704lbs @ 1.300" I washed em up and picked a port and flow tested it. On a 4.06" bore @ 28" H20 they went:

.100 66.5

.200 133

.300 189.1

.400 241.7

.500 287

.600 314.4

.700 327.5

.750 323.5

.800 315.5

They actually peaked @ 330.5 @ .735"

I thought this was pretty good to be honest and with his .700" SR cam it is probably accessing an awful lot of that 330 ish cfm. More to follow in a moment. J.Rob