My Duster Adventures

Well... you would THINK I’d learned my lesson last time I got sick from lack of ventilation but NOPE!! Saturday, when I worked on that header all evening, cutting and welding, I didn’t have any type of forced air movement. Well, Saturday night I didn’t feel real great and when I woke up Sunday morning at 7:30 I felt like absolute crap! Crazy sinus pressure, sore throat and coughing. I slept off and on until 11:30 and felt like crap the rest of the day. Yesterday morning, same story, just not as bad. Now today it basically just feels like I have a head cold. But dammit, I learned my lesson!! Had my wife pick up a box fan for me at Walmart Sunday afternoon.

Last evening I got new bearing races and longer wheel studs put in my 66-70 mustang drum hubs (required to run the 03-04 Cobra brake kit on the mustang ii spindle) I got the one side brakes mocked up and put the wheel on to checkout the look and check the different simulated ride heights. I might have to run the car on the highest setting to start with, which should be 3/4-1” lower than I had it with the torsion bars. If I can run it in the middle setting, I will. That would probably be about 1-1.5” lower than it was and it looks SWEET! Eventually, if possible, I’ll roll the fender lip and do pretty well whatever it takes to run it on the lowest setting. I forgot to take pics of what the different settings look like, so y’all will just have to stay in suspense at least until tomorrow night. Lol sorry.

Now for tonight’s progress. I intended on cutting out the transmission crossmember but I broke my only sawzall blade before I got the second side cut through. So I moved on to other things. First, I cut out the passenger rear floor finally.

I cleaned up that lip in the right side of the pic and painted it with some of that appliance epoxy paint but forgot to take a pic.

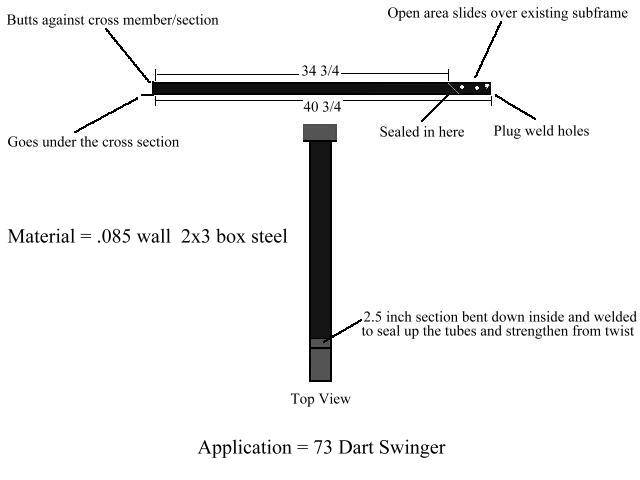

Next, I decided to FINALLY build the subframe connectors that I’ve had materials for for at least 3-4 years! I used @TrailBeast design but ended up making them 45” long and bending a 3” flap down at an angle at 35.5” vs a 2” at 34 3/4”.

Another thing I did differently, is I did some shaping of the rear section, at cut the rear floor pan in order to get the subframe connectors pushed hard up against the rear frame rails.

Here’s a few close ups of the welds just for the heck of it, or for y’all to bust my balls over.

:lol:

This one was my best looking weld.

And these, down in the channel we’re my ugliest.

I going a hole in the ends (I started to, battery died) and dump a bunch of rustoleum paint in it, plug the hole, slosh it around, then dump it out. I’ll spray the outside with the appliance paint. I’m really starting to like that stuff!

Oh yeah, tonight, I had the box fan set in the window and turned on high! Much better! Garage wasn’t as smoke show at any time like it was other days.

Well... you would THINK I’d learned my lesson last time I got sick from lack of ventilation but NOPE!! Saturday, when I worked on that header all evening, cutting and welding, I didn’t have any type of forced air movement. Well, Saturday night I didn’t feel real great and when I woke up Sunday morning at 7:30 I felt like absolute crap! Crazy sinus pressure, sore throat and coughing. I slept off and on until 11:30 and felt like crap the rest of the day. Yesterday morning, same story, just not as bad. Now today it basically just feels like I have a head cold. But dammit, I learned my lesson!! Had my wife pick up a box fan for me at Walmart Sunday afternoon.

Last evening I got new bearing races and longer wheel studs put in my 66-70 mustang drum hubs (required to run the 03-04 Cobra brake kit on the mustang ii spindle) I got the one side brakes mocked up and put the wheel on to checkout the look and check the different simulated ride heights. I might have to run the car on the highest setting to start with, which should be 3/4-1” lower than I had it with the torsion bars. If I can run it in the middle setting, I will. That would probably be about 1-1.5” lower than it was and it looks SWEET! Eventually, if possible, I’ll roll the fender lip and do pretty well whatever it takes to run it on the lowest setting. I forgot to take pics of what the different settings look like, so y’all will just have to stay in suspense at least until tomorrow night. Lol sorry.

Now for tonight’s progress. I intended on cutting out the transmission crossmember but I broke my only sawzall blade before I got the second side cut through. So I moved on to other things. First, I cut out the passenger rear floor finally.

I cleaned up that lip in the right side of the pic and painted it with some of that appliance epoxy paint but forgot to take a pic.

Next, I decided to FINALLY build the subframe connectors that I’ve had materials for for at least 3-4 years! I used @TrailBeast design but ended up making them 45” long and bending a 3” flap down at an angle at 35.5” vs a 2” at 34 3/4”.

Another thing I did differently, is I did some shaping of the rear section, at cut the rear floor pan in order to get the subframe connectors pushed hard up against the rear frame rails.

Here’s a few close ups of the welds just for the heck of it, or for y’all to bust my balls over.

:lol:

This one was my best looking weld.

And these, down in the channel we’re my ugliest.

I going a hole in the ends (I started to, battery died) and dump a bunch of rustoleum paint in it, plug the hole, slosh it around, then dump it out. I’ll spray the outside with the appliance paint. I’m really starting to like that stuff!

Oh yeah, tonight, I had the box fan set in the window and turned on high! Much better! Garage wasn’t as smoke show at any time like it was other days.