pishta

I know I'm right....

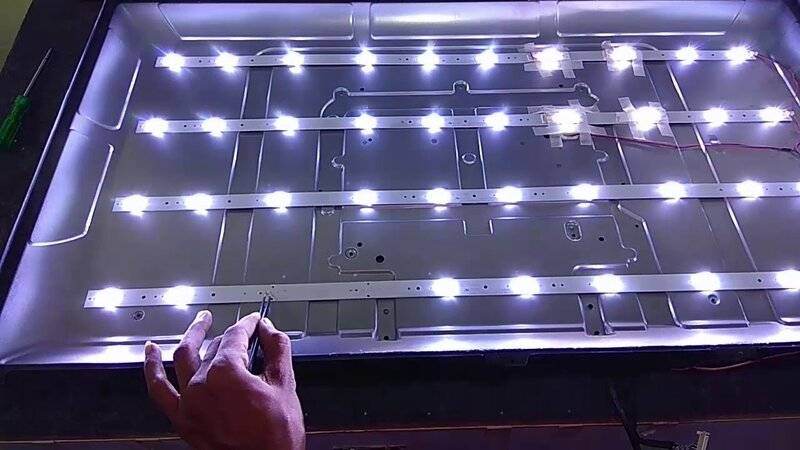

Many new TVs use LED backlights in strips and these are not bulletproof as it may seem. OLED TVs do not have backlights as the O is organic, ie part of the display itself. Little tiny leds in the screen itself. Very slim LED tvs (Ie. LG) use a strip on the bottom that is a continuous row of rectangle LEDs on a aluminum bar shining across the panel. Anyway, back to the subject: usually the screen is LCD glass placed over 2 panels of thin white diffused plastic and then over the 2" deep light box made of reflective white plastic and rows of equally spaces bright white LEDs under round diffuser lens. These are usually on strips of white ribbon tape with a small gold test point flanking each LED. You can use a multimeter in continuity mode to probe these 2 points to make each led glow dimly (make sure polarity is correct as a LED is still a diode).

. If your TV does not turn on, power light flashes or has only audio with images visible on the dark screen using a flashlight, your backlight may be bad. These are set up in series so just like a string of Christmas lights, if one led fails, it takes the whole stip out and can take the whole array down. My 43" example had 5 strips of 10 LEDs for 50 total with a total draw of about 37V per string, 3.7v per LED. My power supply had 3+2 37 volt feeds off to the strips. All my 12, 5 and 3.3v power levels on the power board checked out on the labeled plug twat points so I was certain the strips themselves were bad. You can bypass the bad leds with a lead across the 2 test points and probably won't even notice 1 or 2 out but I found 4 bad on 3 different strips. I'm not sure the power board will continue to feed 37v to a bad strip for safety sake and since there are only 2 circuits (3+2 on my sharp 43") both shut down. You can unsolder the bad leds and replace with super bright 3.7v white leds or the stock flat chip style but it will be a little harder to resolder the chip style as they are surface mount with the solder points under the chip. The plastic diffuser lens on each LED snaps off with a pair of pliers and will need to be glued back on with its 3 little feet as glue points as the LEDs do get warm and will not hold if glue is right on led face. Good luck. It's worth a looksie on a LED TV that has already failed and is heading for the next E-Waste event. Good luck!

. If your TV does not turn on, power light flashes or has only audio with images visible on the dark screen using a flashlight, your backlight may be bad. These are set up in series so just like a string of Christmas lights, if one led fails, it takes the whole stip out and can take the whole array down. My 43" example had 5 strips of 10 LEDs for 50 total with a total draw of about 37V per string, 3.7v per LED. My power supply had 3+2 37 volt feeds off to the strips. All my 12, 5 and 3.3v power levels on the power board checked out on the labeled plug twat points so I was certain the strips themselves were bad. You can bypass the bad leds with a lead across the 2 test points and probably won't even notice 1 or 2 out but I found 4 bad on 3 different strips. I'm not sure the power board will continue to feed 37v to a bad strip for safety sake and since there are only 2 circuits (3+2 on my sharp 43") both shut down. You can unsolder the bad leds and replace with super bright 3.7v white leds or the stock flat chip style but it will be a little harder to resolder the chip style as they are surface mount with the solder points under the chip. The plastic diffuser lens on each LED snaps off with a pair of pliers and will need to be glued back on with its 3 little feet as glue points as the LEDs do get warm and will not hold if glue is right on led face. Good luck. It's worth a looksie on a LED TV that has already failed and is heading for the next E-Waste event. Good luck!