—-

Intakes with flat floors are prone to fuel pooling. Usually from pumping the throttle, which can lead to a pretty good backfire. The burst valve will blow open to alleviate the pressure, reducing the possibility of damaging a manifold, especially if the carb(s) are depressed. These valves have an o-ring for sealing and the spring pressure just slams them shut again.

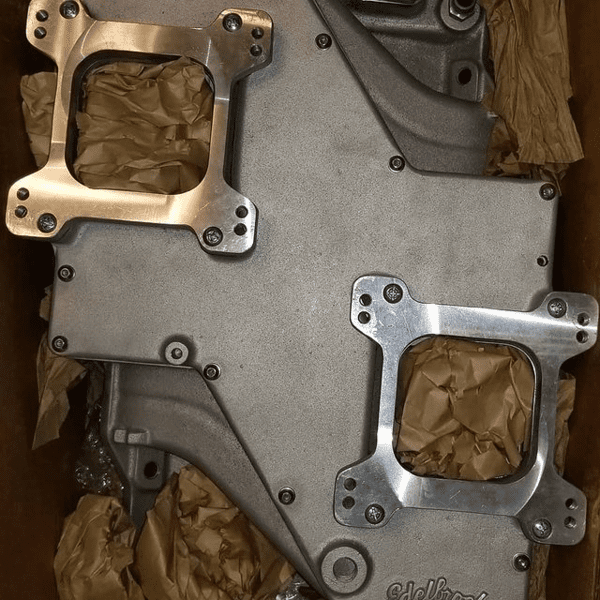

This is a 440-25 Indy intake that I used to run on my max wedge car. It’s got a very flat floor and I’ve experienced numerous back fires with it. There’s a knack to starting them, I never mastered it though.. I purchased this intake used, and it already had these burst valves installed on each side of it. These particular burst valves have a thin layer of pop or beer can aluminum that would just tear apart during a backfire and a guy would have to replace the torn aluminum before starting. A good reason to stop and have a beer for the patch. Haha. The COMP decal is pasted on top of the aluminum.

View attachment 1715700316

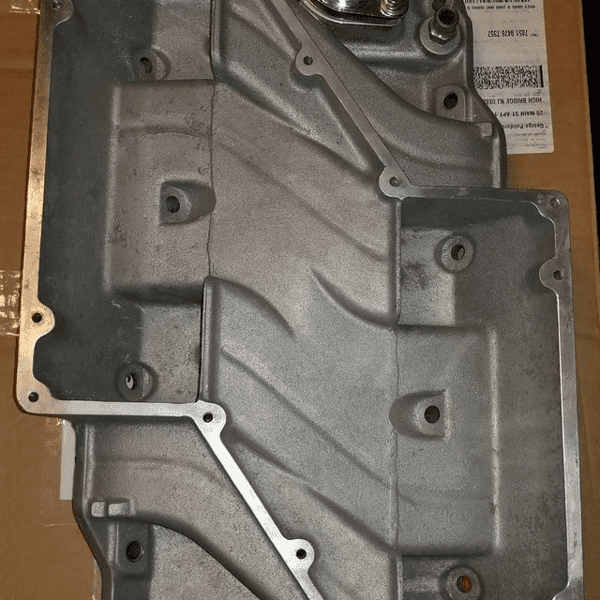

There are lots of fellows that have had pretty good backfires resulting in a top plate being blown off, threads being pulled out of the intake, some fellows have had the epoxy inside of reworked intakes broken loose, some have had fires. Back to my hemi intake, I chose to make these burst valves just in case.

And it did turn out that I had 2 wires crossed and sure enough, I had a backfire on the Dart. The left side valve slammed open and I know they work. Hope this helps, lots of guys have stories about this topic.