moparmat2000

Well-Known Member

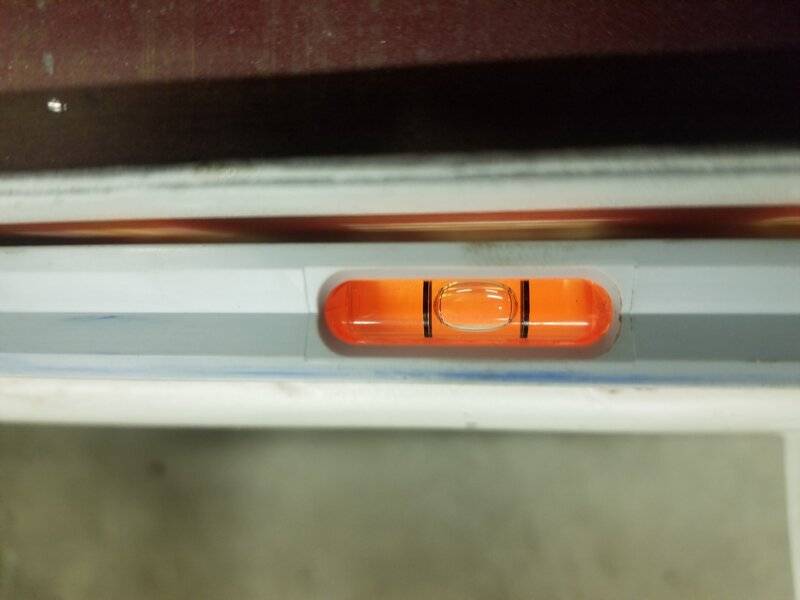

Not sure where to put this. In engine or trans, but the question is ultimately trans related. I have my car jacked, shimmed and leveled in my shop on 4 axis. I set a mock block in place and an intake manifold on it with an angle protractor. With the chassis dead level, should the carb base be level as well? I am thinking so because this sets the engine at a downward angle at the back, but I want more information. I am getting ready to mock up the trans crossmember for a 42RH. And build that while the floor is out for replacement. This would make it all much easier to do. Pix are radiator, both door sills, across the trunk floor, and the carb flange on the intake.

Thanks

Matt

Thanks

Matt