R3W7 Assembly

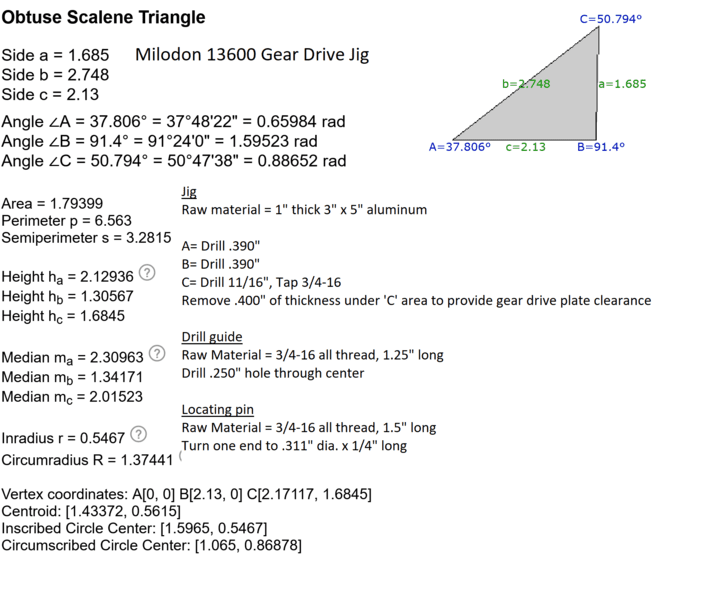

I'm really not a drawing guy....but here are the coordinates and basic details. You need a mill (preferably with DRO) and a lathe to make this. You could substitute a smaller diameter threaded rod if needed. The purpose of the threaded 'inserts' is to allow you to install the jig with the dowel locator in place, then unthread it and install the drill guide without disturbing the jig itself.

The .390" holes are not critical...it's probably just as well to go as big as 7/16" to start with so you had enough movement.

I'm really not a drawing guy....but here are the coordinates and basic details. You need a mill (preferably with DRO) and a lathe to make this. You could substitute a smaller diameter threaded rod if needed. The purpose of the threaded 'inserts' is to allow you to install the jig with the dowel locator in place, then unthread it and install the drill guide without disturbing the jig itself.

The .390" holes are not critical...it's probably just as well to go as big as 7/16" to start with so you had enough movement.