P.P.W9's and the goal of more HP

Not much progress due to SLOW parts coming in. As it stands i am waiting for 6 exhaust seats to come in and then I have all of the parts necessary to complete this project.

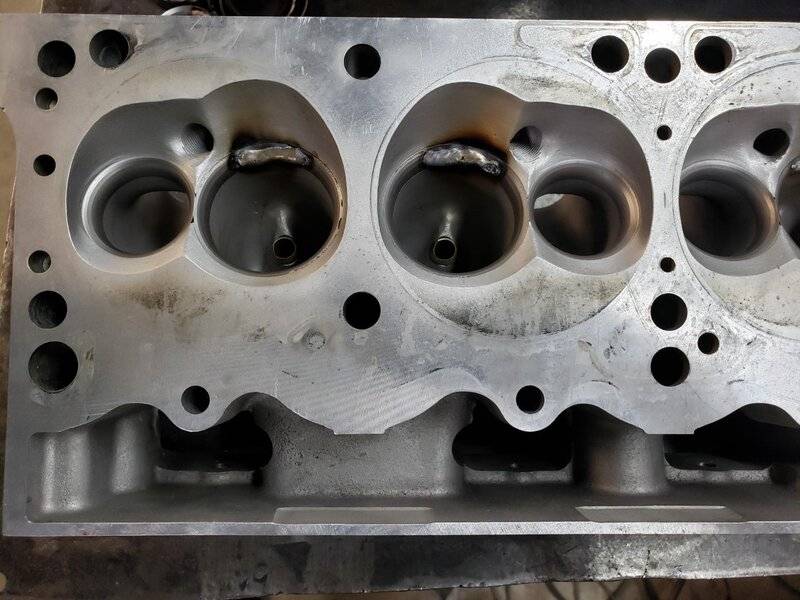

I really hate cutting seats out of cylinder heads--these powdered metal seats are hard and will be hell on the cutter inserts. Sunnen is charging insane amounts for their automotive consumables and non-consumables. I figured why not TIG a bead of stainless onto the back side (from the port entrance) and drive them out with a long chisel (ejector pin). The welding will induce heat and then when it cools should shrink and distort the seat--the bead will also give me something to strike.

It worked excellent with no trauma to the cylinder heads. 125 amps an inch of stainless (nothing else seems to work as well joining dissimilar metals) a few minutes of cool down and a few wacks with a hammer. They popped out nicely. Onto the next step-guide work. J.Rob

Not much progress due to SLOW parts coming in. As it stands i am waiting for 6 exhaust seats to come in and then I have all of the parts necessary to complete this project.

I really hate cutting seats out of cylinder heads--these powdered metal seats are hard and will be hell on the cutter inserts. Sunnen is charging insane amounts for their automotive consumables and non-consumables. I figured why not TIG a bead of stainless onto the back side (from the port entrance) and drive them out with a long chisel (ejector pin). The welding will induce heat and then when it cools should shrink and distort the seat--the bead will also give me something to strike.

It worked excellent with no trauma to the cylinder heads. 125 amps an inch of stainless (nothing else seems to work as well joining dissimilar metals) a few minutes of cool down and a few wacks with a hammer. They popped out nicely. Onto the next step-guide work. J.Rob