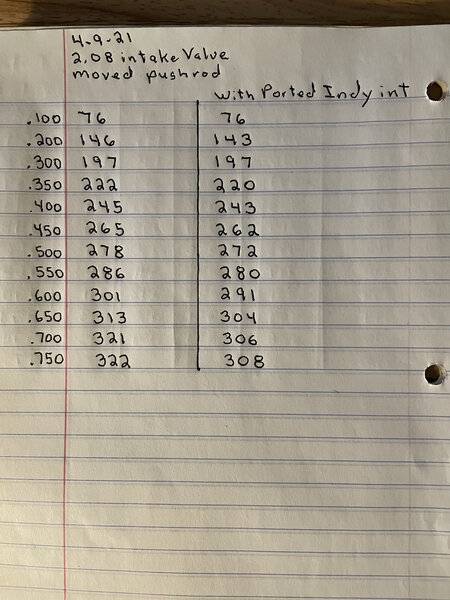

Well is time to stop fooling around and get this 408 together for race season. I had a number in my head (330 cfm) that I was aiming for on this project. I actually hit 333cfm at .750 but I wasn’t happy with the mid lift numbers and with me only running a .650 lift I changed up the short side shape to concentrate on the lower lift numbers. First off I will never do this again in my life moving the pushrod over that far with all the extra work involved. Head flow numbers left column and with ported Indy intake numbers on the right. Hopefully this will get me some 9.50’s soon

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

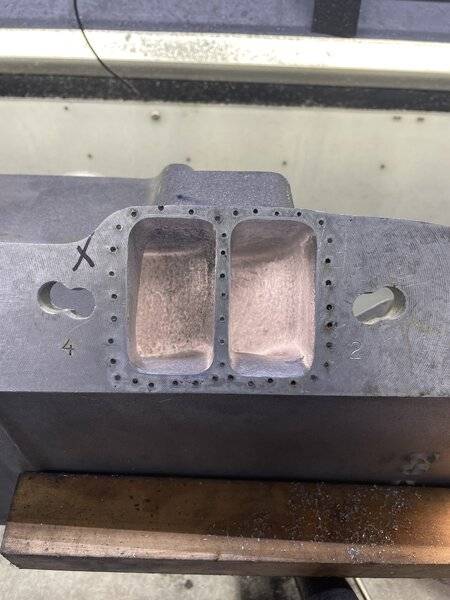

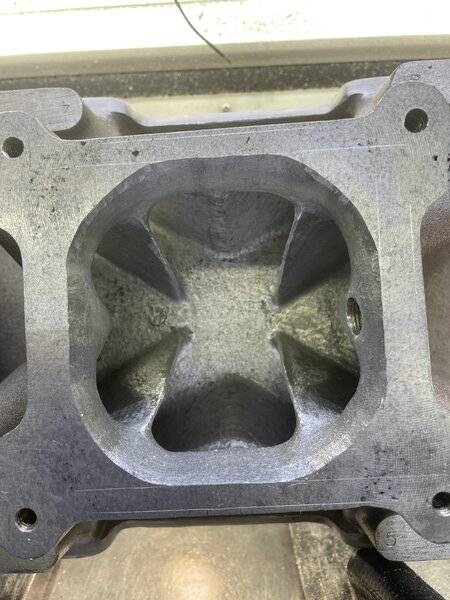

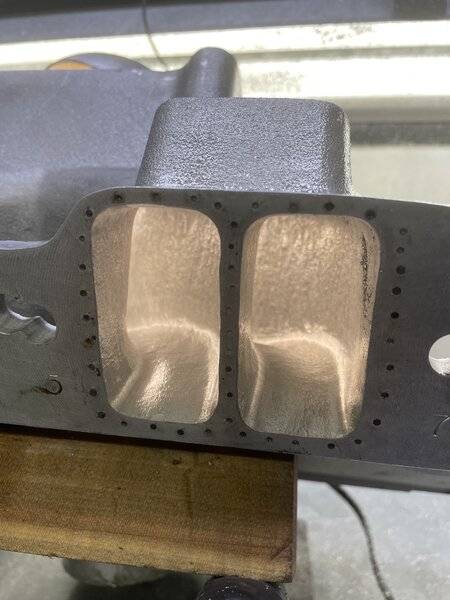

Edelbrock head and ported Indy intake

- Thread starter pittsburghracer

- Start date

-

Indy intake

not finished completely yet but pretty close.

not finished completely yet but pretty close.

I talked to Edelbrock about making me a set of heads with the push rod moved over to 6 pack specs, they said NO. And that was that, he told me they would have to redesign the whole cad program to do it. Ha Ha Ha you got to be kidding me. I know a couple kids that could redraw that in a heart beat, maybe you should hire them. He got pissy and I hung up.

Nice job on the ports, I hope you get in the mid 9's.

I'll be watching.

Nice job on the ports, I hope you get in the mid 9's.

I'll be watching.

PRH

Well-Known Member

Nice job.

Minimal losses with the manifold attached.

It looks like you were able to get rid of some of the radius under the 45.

Btw....... that’s waaay too much work for me.

Minimal losses with the manifold attached.

It looks like you were able to get rid of some of the radius under the 45.

Btw....... that’s waaay too much work for me.

PRH

Well-Known Member

I talked to Edelbrock about making me a set of heads with the push rod moved over to 6 pack specs.

That’s basically what the Indy TA head is.

MP was also selling a version of those.

There are a few threads on here discussing them.

I think Mancini had some of the MP ones on close out last year.

I have no doubt you will achieve your goal of 9.50's.

I have no doubt you will achieve your goal of 9.50's.You are so humble.

Nice job.

Minimal losses with the manifold attached.

It looks like you were able to get rid of some of the radius under the 45.

Btw....... that’s waaay too much work for me.

Ya I started off by just doing a deeper 60,45,30, and a 15 but then I ended up opening up the throat .030 and I’m still probably only at 87% valve ratio. With the .650 cam I’m running I’m pretty satisfied or I would open it up closer to 90%. It’s time to move on. Lol

Those ports are sexy! Nice work.

A few years back Edelbrock was going to send us a set of heads to test and 'work over'. Imagine.....somehow they managed to hang up before getting any of our contact information. I'm sure it worked out for the best. We'd of gotten 'worked over' somehow.I talked to Edelbrock about making me a set of heads with the push rod moved over to 6 pack specs, they said NO. And that was that, he told me they would have to redesign the whole cad program to do it. Ha Ha Ha you got to be kidding me. I know a couple kids that could redraw that in a heart beat, maybe you should hire them. He got pissy and I hung up.

Nice job on the ports, I hope you get in the mid 9's.

I'll be watching.

Understood......I feel the only way that is worth it, is if you're doing it for yourself.Nice job.

Minimal losses with the manifold attached.

It looks like you were able to get rid of some of the radius under the 45.

Btw....... that’s waaay too much work for me.

A few years back Edelbrock was going to send us a set of heads to test and 'work over'. Imagine.....somehow they managed to hang up before getting any of our contact information. I'm sure it worked out for the best. We'd of gotten 'worked over' somehow.

For a head that’s many many years old they don’t work bad but they are what the are. You can only make the short turn so big the way they are made. Controlling 400 FPS across the whole short side is hard to do and results are limited. I hit 318 cfm without moving the pushrod but the intake helped me hit that number and actually raised up because of the intake. Those head ran 10.11 in my sons duster with a 727 at 3250 pounds on a worn out engine. And 9.74 in my duster at 2860 pounds with a powerglide. As you can see the work involved isn’t worth it.

Understood......I feel the only way that is worth it, is if you're doing it for yourself.

i would have been screwed without my buddies help. I tried drilling a new pushrod hole on my drill press and ended up ripping the aluminum rod out and having to epoxy a new one back in and grinding it all back out again. Even using my buddies mill we worked hours on them getting the proper angles set and making new holes. And I still had lots to remove with a burr (one head done) and checking them for clearance on the engine. Don’t forget I also order two different sets of custom Harlan Sharp intake rockers. Hopefully my next new set of heads will be Edelbrock Victor heads and I won’t even let them stock.

Sometimes the hardest person to please is yourself. When I start out flow testing an intake I ported or in the process of porting I will usually test an inboard port of the intake. (3-4-5-6) because if I can get good numbers out of them the outboard ports are usually a cakewalk. The numbers I posted above were from number 4 runner. Although ok I hate the way Indy intakes, super Victor and a couple others leave a ton of material that shield the inboard runners. For the test above I cut down the divider about 1/4 inch to open it up some. It worked but while cutting down the other 3 dividers I get the bright idea to open the plenum up some. I wish I would have taken better pictures but between the ones above and this one you will get an idea how much material there is.

Being way past burned out on this project and several days of work left on the heads I think I’m now done. I could spend another day making it prettier but pretty is time I don’t have. This is another time I wished I had a Mill instead of doing it all by hand, but I don’t. You wouldn’t believe the amount of aluminum chips on my bench and floor from this project.

Time to finish up the heads and get this engine in the damn Duster

Time to finish up the heads and get this engine in the damn Duster

Last edited:

mopowers

Well-Known Member

Damn, that's a lot of grinding! You may have stated already, but what're the punch marks around the intake ports for?

Damn, that's a lot of grinding! You may have stated already, but what're the punch marks around the intake ports for?

That helps to hold the intake gasket in position. Gives it a little bite.

SS Lancer

Well-Known Member

Are these Victor heads ?Well is time to stop fooling around and get this 408 together for race season. I had a number in my head (330 cfm) that I was aiming for on this project. I actually hit 333cfm at .750 but I wasn’t happy with the mid lift numbers and with me only running a .650 lift I changed up the short side shape to concentrate on the lower lift numbers. First off I will never do this again in my life moving the pushrod over that far with all the extra work involved. Head flow numbers left column and with ported Indy intake numbers on the right. Hopefully this will get me some 9.50’s soon View attachment 1715720951

SS Lancer

Well-Known Member

Very niceBeing way past burned out on this project and several days of work left on the heads I think I’m now done. I could spend another day making it prettier but pretty is time I don’t have. This is another time I wished I had a Mill instead of doing it all by hand, but I don’t. You wouldn’t believe the amount of aluminum chips on my bench and floor from this project.

Time to finish up the heads and get this engine in the damn Duster

View attachment 1715724313View attachment 1715724314View attachment 1715724315View attachment 1715724317View attachment 1715724318

Are these Victor heads ?

nope small block Edelbrock heads with the pushrod moved and a 2.08 valve.

SS Lancer

Well-Known Member

10-4 , thank younope small block Edelbrock heads with the pushrod moved and a 2.08 valve.

PRH

Well-Known Member

Nice!

Did I mention how that was waaaaayy too much work for me??

That would get a very polite “no thank you” from me.

Did I mention how that was waaaaayy too much work for me??

That would get a very polite “no thank you” from me.

yellow rose

Overnight Sensation

Nice!

Did I mention how that was waaaaayy too much work for me??

That would get a very polite “no thank you” from me.

He certainly is the self abusement director as far as porting goes. I do stuff like that, but not very often. Way too much work. I still have to finish my tunnel ram. And my W2 heads. Hopefully before I die.

that is one hell of a nice job you did . Wish I had the time an skills to do thatnope small block Edelbrock heads with the pushrod moved and a 2.08 valve.

that is one hell of a nice job you did . Wish I had the time an skills to do that

Thanks. I appreciate it and I figured it was doable but like I said it’s not worth the effort unless it shows me some crazy performance numbers. I get bored on projects that take this amount of effort anymore and it takes time away from other projects that I should be working on.

-