Rocker arm recommendations?

Most, if not all, mass produced Mopar rockers.

Also, the ratio is observed on the valve side, not determined. It is determined by the fulcrum length divided by the center to center distance of the fulcrum, and the pivot center of the adjuster to pushrod interface. If the adjuster side of the rocker is not correctly designed, or not set up properly, the input values on the pushrod side will be wrong, and the resulting ratios will not be constant. As the rocker sweeps on the valve side, it also sweeps on the pushrod side, and that affects ratio. If the pushrod side is right (rocker design), and the fulcrum position is right (stand position), the ratio remains constant

I had this conversation yesterday with one of my rocker vendors, and he said one of their sponsored BB Chevy race cars ran their rockers with 850# of open pressure for multiple seasons without issue. They built a new motor with different heads that had a modified valve angle, and using the same valvetrain components, now they can't keep pushrods in the motor and it is breaking rockers. In reality, that change in valve angle required a different rocker design and set up.

That's why I have T&D make custom rockers to my spec for many Mopar applications. I don't do it because I'm bored and need something to occupy my time. On the contrary, I wish I had more time. I don't advertise these rockers, yet I have been selling quite a few of late, because guys who want everything right find out about them and call. I even have some running down under in Australian Pro Stock.

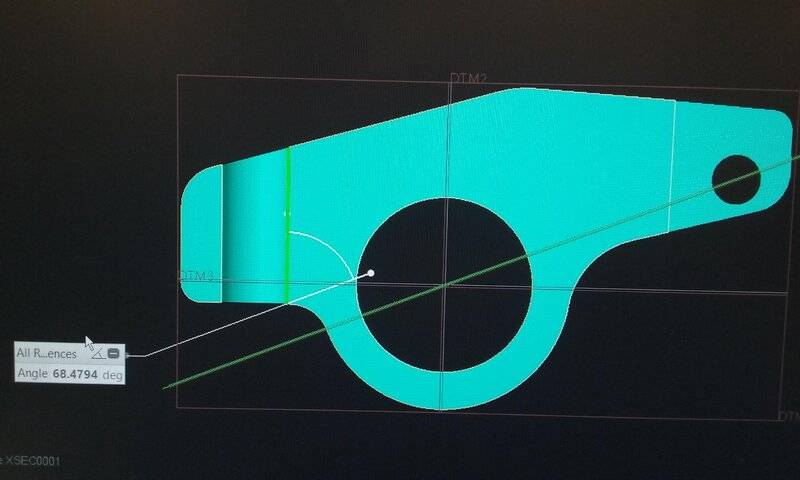

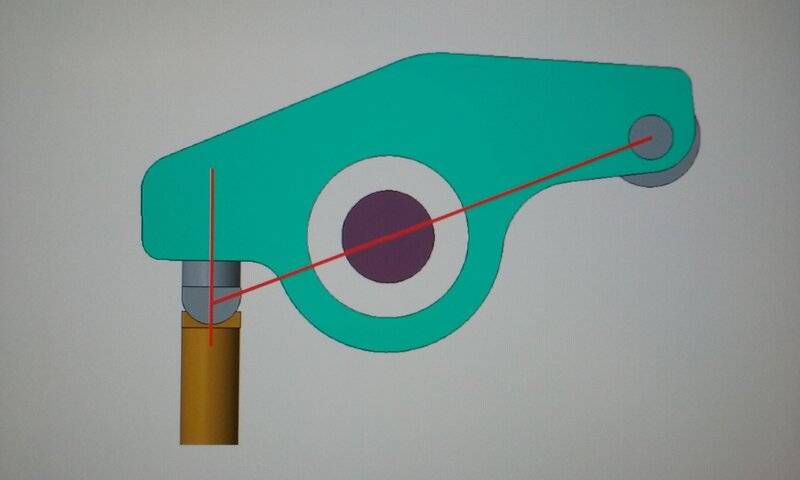

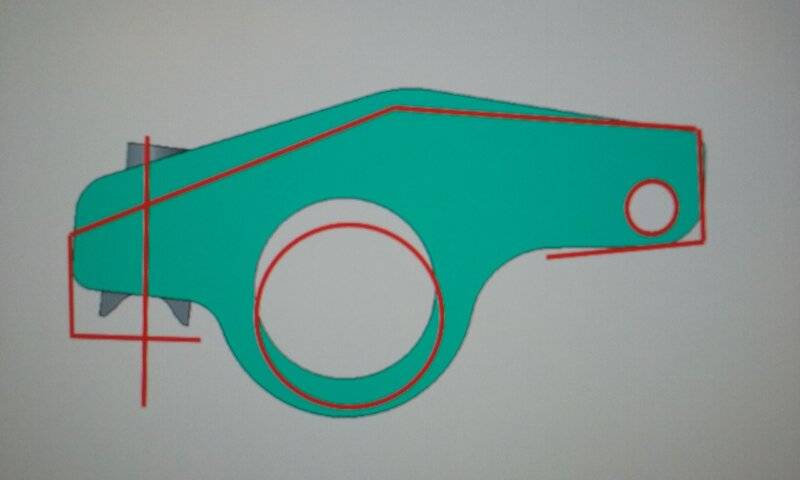

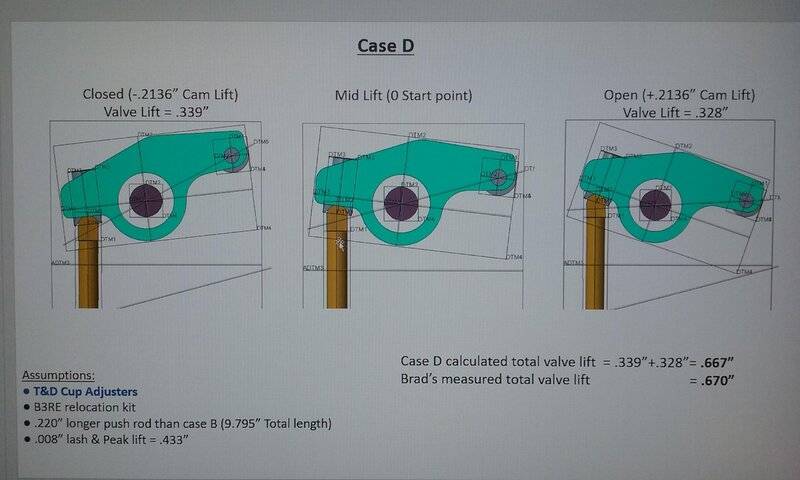

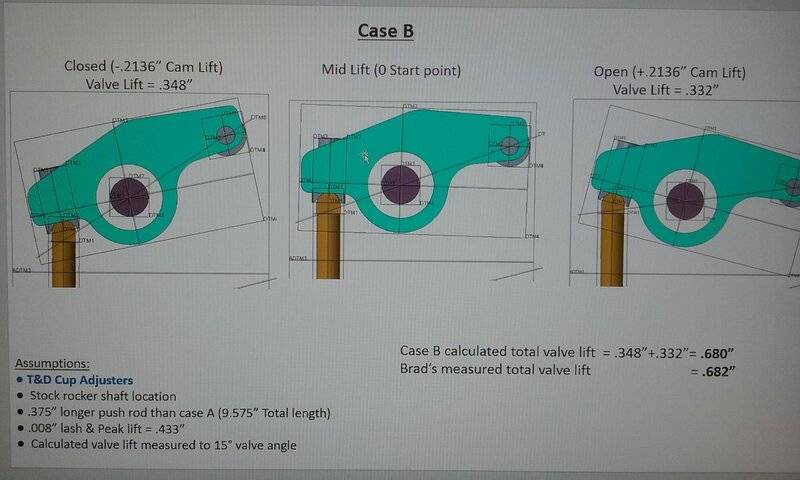

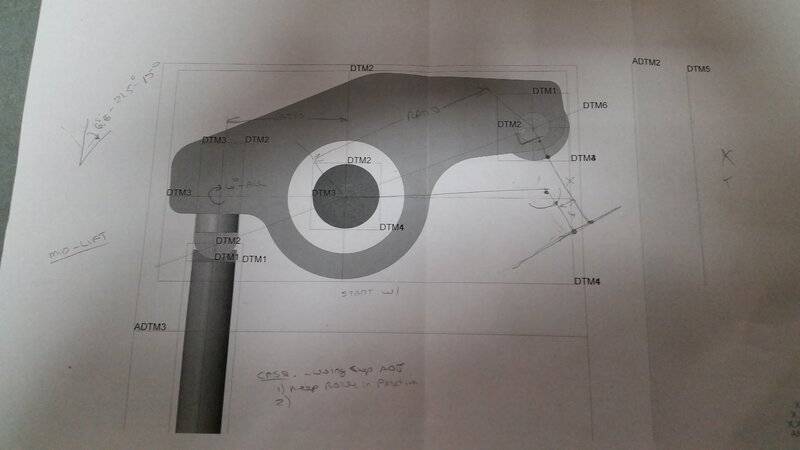

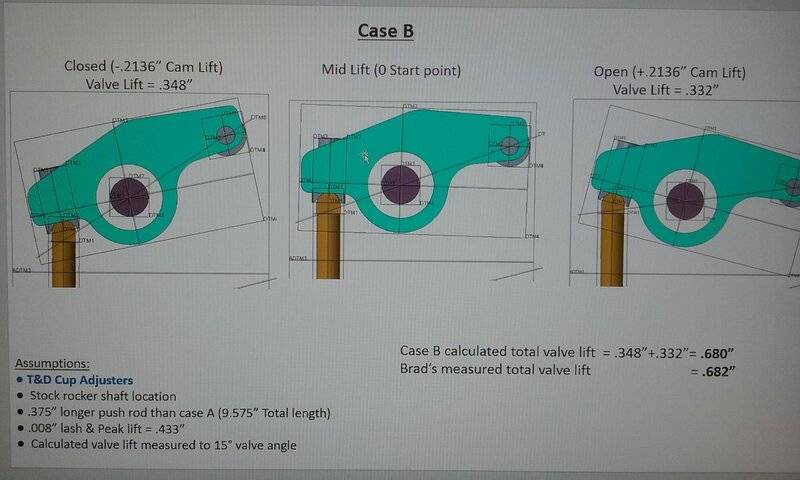

I've also done some of my own testing and research into rocker design and issues with ratio. Check out these "Mopar" rockers that leave a lot to be desired. You can see where the ratios did not remain constant because of the poor adjuster position. This is just a sample of the work we have done to try to build a better mouse trap. Btw, this was after converting to a cup adjuster to increase efficiency, but it was still off a bunch.

In the end, you are welcome to disagree with me all you want. I have no problem with debate, and think it is valuable to society. I have been able to make my case, and you are welcome to still disagree. But, it was never really about that. My response was about the advice to take everything I say with a grain of salt because you disagree with one paragraph, or even a few sentences in a tech article. To that, I will defend myself, and my reputation for giving good advice. Now, I must get back to work.

Most, if not all, mass produced Mopar rockers.

I know what you were referring to, and addressed it in my last post. You are referring to shoe type rocker geometry, which is what I explained in paragraph 2 of that tech article. There are many people who try to treat a roller rocker as having the same geometry as a shoe rocker, and that is incorrect. They are significantly different.

Again, using shoe rocker geometry on a roller rocker. The point of rotation is at the center of the roller axis, and not at the contact point like a shoe rocker. The effective fulcrum length remains constant.

Also, the ratio is observed on the valve side, not determined. It is determined by the fulcrum length divided by the center to center distance of the fulcrum, and the pivot center of the adjuster to pushrod interface. If the adjuster side of the rocker is not correctly designed, or not set up properly, the input values on the pushrod side will be wrong, and the resulting ratios will not be constant. As the rocker sweeps on the valve side, it also sweeps on the pushrod side, and that affects ratio. If the pushrod side is right (rocker design), and the fulcrum position is right (stand position), the ratio remains constant

No kidding! How many people realize the complexity of the valvetrain on a canted valve, dual angle lifter application? How many rocker sets for a BB Chevy have a different rocker design for the intake vs the exhaust? If they want it to be right, that is entirely necessary. But, that drives up cost, increases overhead, increases confusion among those who don't understand the complexity, and thereby reduces sales. Keep it simple and make more money. Most people only check ratio at full lift, so as long as it's close there, it's a winner. right?

I had this conversation yesterday with one of my rocker vendors, and he said one of their sponsored BB Chevy race cars ran their rockers with 850# of open pressure for multiple seasons without issue. They built a new motor with different heads that had a modified valve angle, and using the same valvetrain components, now they can't keep pushrods in the motor and it is breaking rockers. In reality, that change in valve angle required a different rocker design and set up.

That's why I have T&D make custom rockers to my spec for many Mopar applications. I don't do it because I'm bored and need something to occupy my time. On the contrary, I wish I had more time. I don't advertise these rockers, yet I have been selling quite a few of late, because guys who want everything right find out about them and call. I even have some running down under in Australian Pro Stock.

I've also done some of my own testing and research into rocker design and issues with ratio. Check out these "Mopar" rockers that leave a lot to be desired. You can see where the ratios did not remain constant because of the poor adjuster position. This is just a sample of the work we have done to try to build a better mouse trap. Btw, this was after converting to a cup adjuster to increase efficiency, but it was still off a bunch.

In the end, you are welcome to disagree with me all you want. I have no problem with debate, and think it is valuable to society. I have been able to make my case, and you are welcome to still disagree. But, it was never really about that. My response was about the advice to take everything I say with a grain of salt because you disagree with one paragraph, or even a few sentences in a tech article. To that, I will defend myself, and my reputation for giving good advice. Now, I must get back to work.