Rocker arm recommendations?

[1] Wait a minute! You agree with me on something! How is that possible if anything I say is questionable? I disagree with a lot of people on certain things, including Smokey Yunick and David Vizard, but I don't assume they don't know anything at all.

[2] As I have been saying all along, if the rocker is not designed and set up properly, you will not get an accurate transfer of cam lobe information to the valve. Obviously, Vizard was working with a bunch of improperly designed rockers. After all, if they were right, they would have all been the same. The rocker can be manipulated to do things the cam lobe was not designed to do, and that usually doesn't work out too well.

[3] What is this "ratio on the valve side"? Ratio is not dependent on the valve side only. You and Smokey say I am incorrect. Well, you and the spirits summon ole Smokey from the afterlife, and make your argument with someone who has a much higher pay grade than I do. That would be the author of natural law, of which mathematics falls under. Mankind didn't invent math, they simply discovered it. You know, like gravity and electricity.

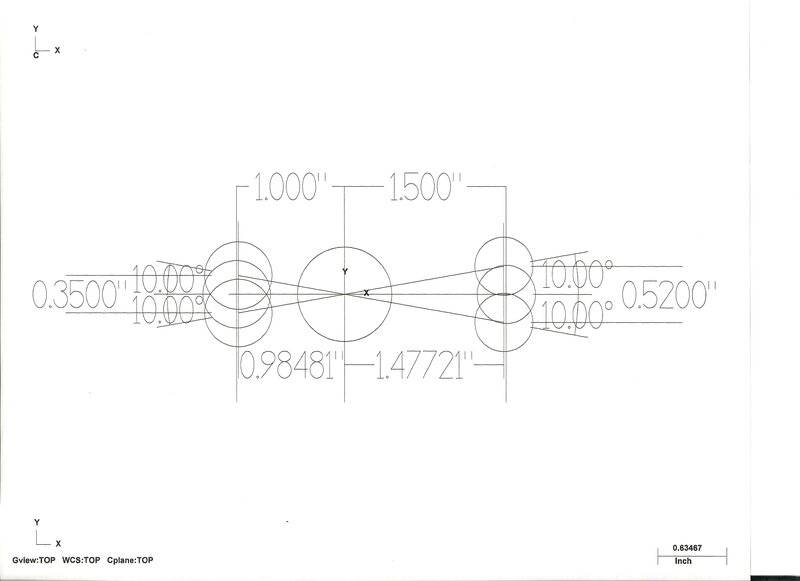

For your benefit, and others, I have drafted a simple fulcrum, which is all a rocker arm is. The only difference is variations for a specific application.

As you can see, a simple 1.5 ratio on the perpendicular plane has a fulcrum length of 1.500 inches, and the adjuster centerline to fulcrum is 1.000 inch. Now, with a 10 degree rotation, both above, and below the perpendicular line, the lengths change to 1.47721 inches on the valve side, and .98481 inch on the pushrod side. What is 1.47721"/.98481"? Well, at this number of decimal places, that comes out to 1.4999949229. Now, would you like to quibble over 5 MILLIONTHS of a point?

For reference, the combined 20 degrees of rotation with this fulcrum example amounts to a .350" cam lobe lift, and a .520" gross valve lift, which is pretty common for a performance street or street/strip cam, so it's easily relatable.

[4] I never said that, because the ratio is not solely on the valve side. I said the geometry is different.

I'm done, and again, I have made my case. I won't continue to beat a dead horse, and this is really hurting my productivity. FWIW, this battle was fought several years ago on Moparts.

In reference to;

[1] Wait a minute! You agree with me on something! How is that possible if anything I say is questionable? I disagree with a lot of people on certain things, including Smokey Yunick and David Vizard, but I don't assume they don't know anything at all.

[2] As I have been saying all along, if the rocker is not designed and set up properly, you will not get an accurate transfer of cam lobe information to the valve. Obviously, Vizard was working with a bunch of improperly designed rockers. After all, if they were right, they would have all been the same. The rocker can be manipulated to do things the cam lobe was not designed to do, and that usually doesn't work out too well.

[3] What is this "ratio on the valve side"? Ratio is not dependent on the valve side only. You and Smokey say I am incorrect. Well, you and the spirits summon ole Smokey from the afterlife, and make your argument with someone who has a much higher pay grade than I do. That would be the author of natural law, of which mathematics falls under. Mankind didn't invent math, they simply discovered it. You know, like gravity and electricity.

For your benefit, and others, I have drafted a simple fulcrum, which is all a rocker arm is. The only difference is variations for a specific application.

As you can see, a simple 1.5 ratio on the perpendicular plane has a fulcrum length of 1.500 inches, and the adjuster centerline to fulcrum is 1.000 inch. Now, with a 10 degree rotation, both above, and below the perpendicular line, the lengths change to 1.47721 inches on the valve side, and .98481 inch on the pushrod side. What is 1.47721"/.98481"? Well, at this number of decimal places, that comes out to 1.4999949229. Now, would you like to quibble over 5 MILLIONTHS of a point?

For reference, the combined 20 degrees of rotation with this fulcrum example amounts to a .350" cam lobe lift, and a .520" gross valve lift, which is pretty common for a performance street or street/strip cam, so it's easily relatable.

[4] I never said that, because the ratio is not solely on the valve side. I said the geometry is different.

I'm done, and again, I have made my case. I won't continue to beat a dead horse, and this is really hurting my productivity. FWIW, this battle was fought several years ago on Moparts.