Carb tuning, larger accelerator pump nozzle?

Lots of thoughts, starting with I wish you changed only one or two things. :poke:

That said I'll try to focus on what I think relates most to the shift into 1st gear.

How much throttle are you using to get/keep the rpms up as you let out the clutch?

(Quick Fuel 650 SS, Mech Secondary) TKO 600 and 3.91:1 gears

Set up A: really bad lean stumble just coming off the clutch. The slower the leaner then it would catch up

71 IAB

Set up B1

67 IAB

Setup B2

33 accelerator pump nozzle on the primary side

Setup B3

White pump cam and adjusted the pump arm, that helped a little,

Setup B4

blue pump cam

The observation "the slower the leaner" was the clue that I think everyone is working from. Very little pump shot should be needed with slow throttle openings. Green or blue should have enough movement right off of idle to cover.

Setup C1

IFR moved down Size? Primary only - yes?

Plugged the top two Emulsion ports (not sure it "port" is he correct term) so the bottom 4 are still open on both blocks.

Call it whatever you like. Tuner was trying to get people to call them something other than "emulsion" holes but e-holes is what everyone seems to use.

Primary & Secondary block

top e-hole. plugged

middle e-hole: .028

bottom e-hole: .028

PMJ 68 (was 70)

Pri Accl Pump: Blue Cam

Prim Shooters : 35

T-slots: .035-.040

Areas to explore; experiment with:

Primary T-slot. I think with a Quick Fuel as well as many newer Holleys .035 to .040" may be too much for two reasons.

One is they often have longer or wider t-slots than the older Holleys. Try a little less which may involve readjusting the idle mix screws.

Secondary Side: If this is a "two corner" idle mixture control, the secondary t-slots should hardly be visible if at all.

PMJ: Leave it alone. Later you can test under what cruise speed and rpm the PMJs start to have a noticible effect. On my car its close to 3000 rpm, 60-65 mph before the main circuit has really taken over. Your car will be different but crusiing at 30, 40 or maybe even 50 mph will still be mostly on the "transition" circuit.

IFR: Maybe I missed it but I didn't catch the primary IFR size. Taking this up one size should have a big effect. On an engine with somewhat poor idle vacuum, it might need something fairly large like .035" On an engine with very strong idle vacuum it might need to be maybe as small as .028"

IAB: I don't have a starting point or recommendation here without knowing the IFR and the vacuum situation. Make a change but don't be too surprised if it doesn't respond the way you might have guessed.

Here's the thing with a long or wide t-slot, the portion exposed to atmospheric pressure is supplying more air into the mix than an old school holley. Mderoy's posts are always based on his experience and IMO he's tests pretty carefully.

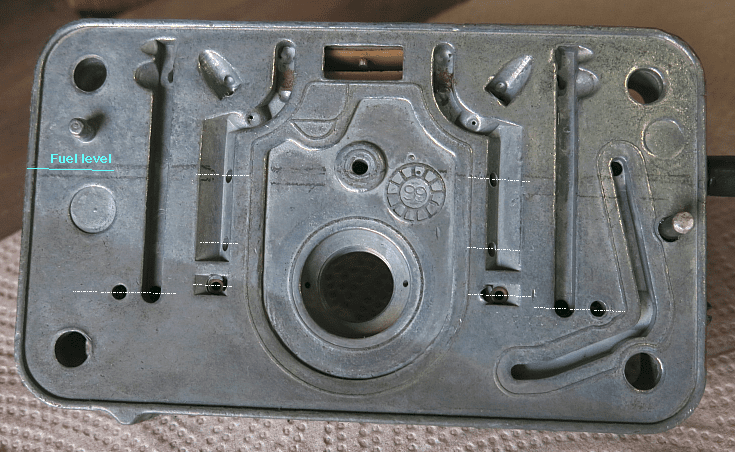

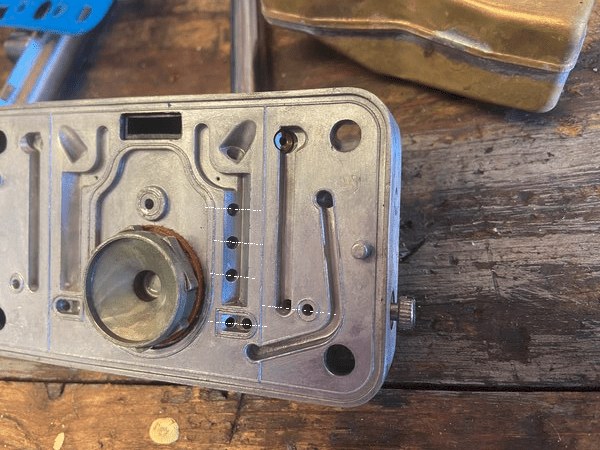

Lets look at the pictures posted earlier for why its hard to generalize.

Notice the hieghts of the e-holes, the idle and transition feeds from the downwell, and even the connection from the jets is different in each block. In some situations this can make a difference.

Holley Primary block from a 650 vac seconday (List 80783)

HR 850

QF 650SS

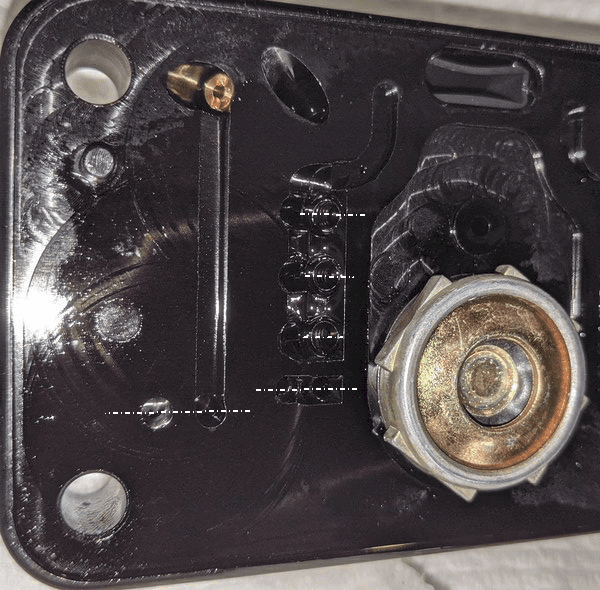

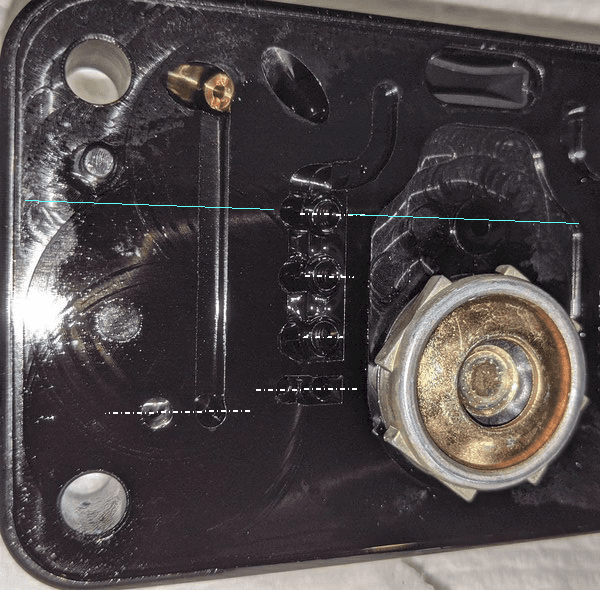

Depending on where the fuel level is, I'd probably plug the middle e-hole.

I say that because the bottom hole is still fairly high and the top hole looks about normal.

As long as fuel the main well is at or a drop above the top hole, that should help initialize flow into the main circuit.

Whether that has anything to do with the issue(s) at hand depends on how much throttle and rpm is needed to make the shift.

Low throttle, low rpm it should not have any effect. The effect is when the mains need to start up and begin taking over from the "low speed" circuits.

Injecting air into the fuel at the top of the well makes that fuel less dense and lowers the viscosity. So now the fuel flows more quickly and the air blowing through the hole speeds its movement toward the booster.

If after systematic experimenting shows the t-slots are two big or too long, then the thing to do will be to is shorten them or restrict the feed to them.

First work through a couple different IFR and IAB combos, especially with a little less t-slot exposure. Then decide.

Lots of thoughts, starting with I wish you changed only one or two things. :poke:

That said I'll try to focus on what I think relates most to the shift into 1st gear.

How much throttle are you using to get/keep the rpms up as you let out the clutch?

(Quick Fuel 650 SS, Mech Secondary) TKO 600 and 3.91:1 gears

Set up A: really bad lean stumble just coming off the clutch. The slower the leaner then it would catch up

71 IAB

Set up B1

67 IAB

Setup B2

33 accelerator pump nozzle on the primary side

Setup B3

White pump cam and adjusted the pump arm, that helped a little,

Setup B4

blue pump cam

The observation "the slower the leaner" was the clue that I think everyone is working from. Very little pump shot should be needed with slow throttle openings. Green or blue should have enough movement right off of idle to cover.

Setup C1

IFR moved down Size? Primary only - yes?

Plugged the top two Emulsion ports (not sure it "port" is he correct term) so the bottom 4 are still open on both blocks.

Call it whatever you like. Tuner was trying to get people to call them something other than "emulsion" holes but e-holes is what everyone seems to use.

Primary & Secondary block

top e-hole. plugged

middle e-hole: .028

bottom e-hole: .028

PMJ 68 (was 70)

Pri Accl Pump: Blue Cam

Prim Shooters : 35

T-slots: .035-.040

Areas to explore; experiment with:

Primary T-slot. I think with a Quick Fuel as well as many newer Holleys .035 to .040" may be too much for two reasons.

One is they often have longer or wider t-slots than the older Holleys. Try a little less which may involve readjusting the idle mix screws.

Secondary Side: If this is a "two corner" idle mixture control, the secondary t-slots should hardly be visible if at all.

PMJ: Leave it alone. Later you can test under what cruise speed and rpm the PMJs start to have a noticible effect. On my car its close to 3000 rpm, 60-65 mph before the main circuit has really taken over. Your car will be different but crusiing at 30, 40 or maybe even 50 mph will still be mostly on the "transition" circuit.

IFR: Maybe I missed it but I didn't catch the primary IFR size. Taking this up one size should have a big effect. On an engine with somewhat poor idle vacuum, it might need something fairly large like .035" On an engine with very strong idle vacuum it might need to be maybe as small as .028"

IAB: I don't have a starting point or recommendation here without knowing the IFR and the vacuum situation. Make a change but don't be too surprised if it doesn't respond the way you might have guessed.

Here's the thing with a long or wide t-slot, the portion exposed to atmospheric pressure is supplying more air into the mix than an old school holley. Mderoy's posts are always based on his experience and IMO he's tests pretty carefully.

Lets look at the pictures posted earlier for why its hard to generalize.

Notice the hieghts of the e-holes, the idle and transition feeds from the downwell, and even the connection from the jets is different in each block. In some situations this can make a difference.

Holley Primary block from a 650 vac seconday (List 80783)

HR 850

QF 650SS

Depending on where the fuel level is, I'd probably plug the middle e-hole.

I say that because the bottom hole is still fairly high and the top hole looks about normal.

As long as fuel the main well is at or a drop above the top hole, that should help initialize flow into the main circuit.

Whether that has anything to do with the issue(s) at hand depends on how much throttle and rpm is needed to make the shift.

Low throttle, low rpm it should not have any effect. The effect is when the mains need to start up and begin taking over from the "low speed" circuits.

Injecting air into the fuel at the top of the well makes that fuel less dense and lowers the viscosity. So now the fuel flows more quickly and the air blowing through the hole speeds its movement toward the booster.

If after systematic experimenting shows the t-slots are two big or too long, then the thing to do will be to is shorten them or restrict the feed to them.

First work through a couple different IFR and IAB combos, especially with a little less t-slot exposure. Then decide.