1968 GTS 340 with Carter AVS 4966S

I think I understand what you are stating. If a part fails, it can be difficult, expensive or take a long time to get a replacement.

Unfortunately many new parts are inferior that the originals. Thats why I suggest judging each part on its condition. Regardless, having a plan for replacment or repair will also be a good idea. Perhaps some of the other FABO members in the EU and UK can help out.

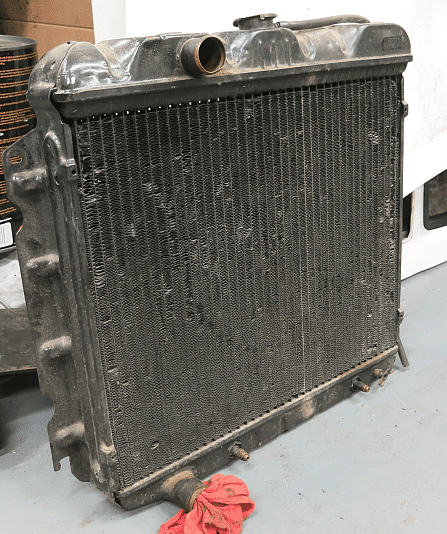

Radiators up through 1969 have a distinct top tank. The bottom tank has an outlet that is on the left side, which matches the short cast iron water pump inlet used through 1969. The fan and fan shroud also match the spacing and the fan blades have a notch in the corner to clear the top tank.

Electric fans are (in my opinion) a problem. They often do a poorer job than the mechanical fans. They require more electric power than the original electrical systems were made to handle. The engines in these cars have plenty of torque and power and the water pump has to be turned mechanically anyway.

For example this is an original radiator for a 1968 with a 318 or 340 v-8

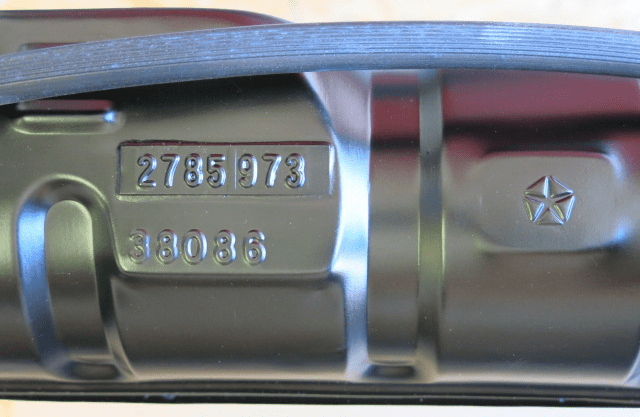

Near the stamped number there should be a specific part number soldered on.

It may be on the back or the top of the tank.

Like this restored one

White arrow points to a notch in the fan blade. This particular fan was used with a fan clutch.

Since you are tuning a mystery distributor, and since the engine can not idle at 700 rpm, the first iteration will have to be a guess. Measuring and plotting timing at several (or many) different rpms, without touching the distributor, will let us see the advance curve. Then you can make a better guess.

Distributor on engine: The lack of vacuum advance only means there is no vacuum advance. Take a picture with the cap and with the cap removed and we can probably identify it.

It could be a lean burn distributor, it could be a race distributor, or it could be a regular distributor someone modified.

The Proform distributor will be a similar situation to your mystery distributor. I don't know what the advance looks like. Only thread about them I found quickly is this one.

You will have to measure the timing to know what the advance curve looks like. Vacuum advance is very helpful for part throttle performance and economy, but can only be implemented if the mechanical timing is correct.

I had been assuming the car had the original points or dual points distributor to go with the original (or similar) carburetor.

Now you are into hot rodding.

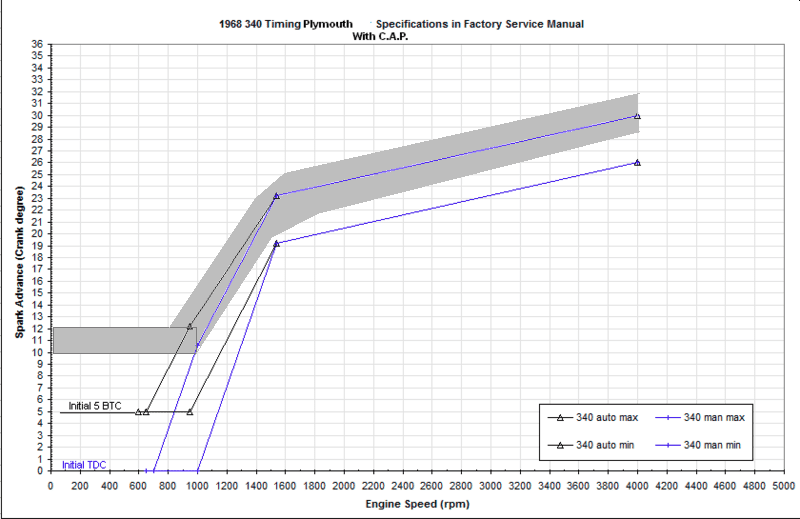

If there is no regulatory need for the CAP, then timing at idle can be 10 to 12 BTDC as the factroy did for the 1967 273 4 bbl. But the timing at higher rpms can't adjvance too quickly if vacuum advance is to be used. If you find the distributor advances quicker than shown in the gray, don't connect the vacuum advance.

When you get the engine idling slow enough that turning the idle mix screws has an effect, turn them out (richer) until the engine smooths, then turn them in slowly. As soon as the engine slows down, turn them back a 1/8 or quarter turn.

*

Mechanical or Centrifical Advance

Compensates for the reduced amount of time (miliseconds) available for the burn as rpm increases. Its not directly proportional because combustion efficiency increases with rpms. This means decreased burn time as rpms climb. A 'low performance' 318 usually has good lower rpm efficiency, but does not gain as much efficiency with increasing rpm. A 'high performance engine' is usually the opposite, poor - slow combustion at low rpms, but more efficient and quicker pressure development at higher rpms.

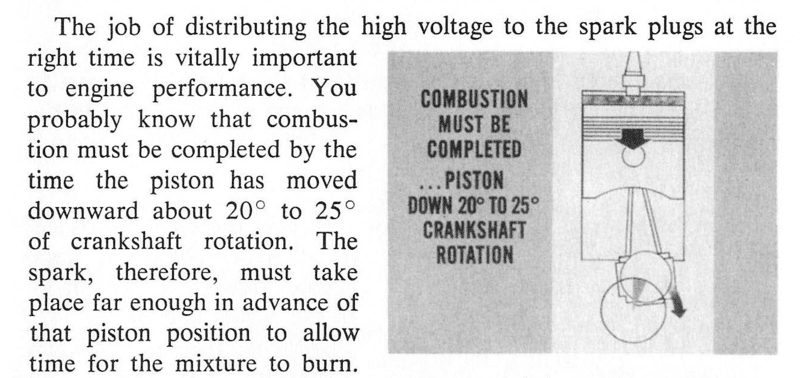

From Chrysler Master Technician's Service Conference.

Vacuum Advance:

p. 6 Ignition System Analysis (Session 259) from the Master Technician's Service Conference

I think I understand what you are stating. If a part fails, it can be difficult, expensive or take a long time to get a replacement.

Unfortunately many new parts are inferior that the originals. Thats why I suggest judging each part on its condition. Regardless, having a plan for replacment or repair will also be a good idea. Perhaps some of the other FABO members in the EU and UK can help out.

This is something I have strong opinions on. Generally its best to fix the original even if it means a new core (most expensive). Mostly for the reasons mentioned above, new is often not made better in terms of fit or material. But what is original? Maybe your car does not have the original radiator?

Radiators up through 1969 have a distinct top tank. The bottom tank has an outlet that is on the left side, which matches the short cast iron water pump inlet used through 1969. The fan and fan shroud also match the spacing and the fan blades have a notch in the corner to clear the top tank.

Electric fans are (in my opinion) a problem. They often do a poorer job than the mechanical fans. They require more electric power than the original electrical systems were made to handle. The engines in these cars have plenty of torque and power and the water pump has to be turned mechanically anyway.

For example this is an original radiator for a 1968 with a 318 or 340 v-8

Near the stamped number there should be a specific part number soldered on.

It may be on the back or the top of the tank.

Like this restored one

White arrow points to a notch in the fan blade. This particular fan was used with a fan clutch.

The process is iterative. In other words you will likely need to repeat the steps several times. When everything was new from the factory, then the timing from 600 to maybe 750 rpm would not change. So a technician could begin with engine idling very close to specified rpm, set the timing, and then adjust the rpm if needed. Then fuel mixture would be adjusted to specification. There was very little adjustment range available in the cars with emissions packages. For several years the idle mixture screws used for tune up were actually idle air bleed adjustments. On those carburetors the idle fuel mixture needle valves were only accessed for major overhauls.

Since you are tuning a mystery distributor, and since the engine can not idle at 700 rpm, the first iteration will have to be a guess. Measuring and plotting timing at several (or many) different rpms, without touching the distributor, will let us see the advance curve. Then you can make a better guess.

Well you are learning. :) One nice thing about learning now is the availablity of Chrysler training material on the internet.*

Distributor on engine: The lack of vacuum advance only means there is no vacuum advance. Take a picture with the cap and with the cap removed and we can probably identify it.

It could be a lean burn distributor, it could be a race distributor, or it could be a regular distributor someone modified.

The Proform distributor will be a similar situation to your mystery distributor. I don't know what the advance looks like. Only thread about them I found quickly is this one.

You will have to measure the timing to know what the advance curve looks like. Vacuum advance is very helpful for part throttle performance and economy, but can only be implemented if the mechanical timing is correct.

I had been assuming the car had the original points or dual points distributor to go with the original (or similar) carburetor.

Now you are into hot rodding.

If there is no regulatory need for the CAP, then timing at idle can be 10 to 12 BTDC as the factroy did for the 1967 273 4 bbl. But the timing at higher rpms can't adjvance too quickly if vacuum advance is to be used. If you find the distributor advances quicker than shown in the gray, don't connect the vacuum advance.

When you get the engine idling slow enough that turning the idle mix screws has an effect, turn them out (richer) until the engine smooths, then turn them in slowly. As soon as the engine slows down, turn them back a 1/8 or quarter turn.

*

Mechanical or Centrifical Advance

Compensates for the reduced amount of time (miliseconds) available for the burn as rpm increases. Its not directly proportional because combustion efficiency increases with rpms. This means decreased burn time as rpms climb. A 'low performance' 318 usually has good lower rpm efficiency, but does not gain as much efficiency with increasing rpm. A 'high performance engine' is usually the opposite, poor - slow combustion at low rpms, but more efficient and quicker pressure development at higher rpms.

From Chrysler Master Technician's Service Conference.

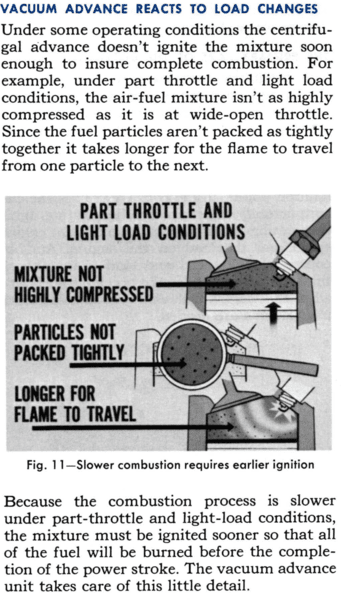

Vacuum Advance:

p. 6 Ignition System Analysis (Session 259) from the Master Technician's Service Conference