For those of you who've made the metering valve modification to your home blasting cabinets, how much better does it make it work? I think I may do it to mine. It works ok, but I think it could be better and if this will help it I may do it. Looks cheap enough.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blasting Cabinet Metering Valve

- Thread starter RustyRatRod

- Start date

-

I meter my cabinet with the air pressure going to the gun. More aggressive media, like 80 aluminum oxide, I turn down to about 80 PSI. My soda blaster I run at full speed, at 135 PSI. For delicate things like alternators, I use organic media, like walnut shells, and adjust the pressure. I have a big 80 gallon 2 stage compressor, so my options are wide open. My cheap HF in line filter/dryer helps, as the weather up here is usually high in humidity. YMMV.

I meter my cabinet with the air pressure going to the gun. More aggressive media, like 80 aluminum oxide, I turn down to about 80 PSI. My soda blaster I run at full speed, at 135 PSI. For delicate things like alternators, I use organic media, like walnut shells, and adjust the pressure. I have a big 80 gallon 2 stage compressor, so my options are wide open. My cheap HF in line filter/dryer helps, as the weather up here is usually high in humidity. YMMV.

I'm not talking about a regulator. I'm talking about an add on metering valve that supplies the media from the bottom of the hopper, where the trap door is to empty the media out.

I understand the difference, Bulldog. I modified my home made Scat cabinet per their instructions. I built mine 20 years ago from their plans. My cabinet has a funnel type trap at the bottom of it. I tried putting my pick up tube at the bottom of the funnel. No good, as the moisture went to the bottom of the collected abrasive it was standing. That's were the moisture collected, too. Depending on how much media you use(I use 50 lbs of 80 grit aluminum oxide), I hard mounted my pick up tube about 3 inches from the bottom of the funnel. I use an old A/C filter with a valve to control how the media is sucked up. I also use a cheap HF filter to supply the air to the cabinet. It might sound strange, but I light my cabinet with an old 150 watt incandescent bulb, which helps dry out the media while blasting. I filter the air with my Craftsman vacuum through another port. It might sound cheesy, but it's served me well over the years. I'll send pictures, if you'd like. Paul.

rklein383

Well-Known Member

- Joined

- Dec 2, 2005

- Messages

- 2,210

- Reaction score

- 1,803

I use an old A/C filter with a valve to control how the media is sucked up.

You lost me on this sentence...

My cabinet is a commercial type, with a cyclone where the media is collected. Bottom has a t. One side is mounted to hopper, and one is to feed the siphon hose. Third is an air bleed, it helps with draft to keep air flowing through siphon. Works well. I use glass bead.

jonn6464

1970 Duster

For those of you who've made the metering valve modification to your home blasting cabinets, how much better does it make it work? I think I may do it to mine. It works ok, but I think it could be better and if this will help it I may do it. Looks cheap enough.

I bought this one off Ebay.

I think it does help with the delivery of blasting media. My issue is that the slope on the floor of my blaster is shallow, so the media doesn't funnel very well into the bottom hole.

But, I would say it does help. Just be prepared to make some mods to your blast cabinet.

80fbody

Well-Known Member

I was looking at this one for mine. Haven't needed the cabinet in awhile so I haven't been frustrated in awhile...lol

BLAST CABINET METERING VALVE Abrasive Sand Media Blasting Harbor Freight Upgrade | eBay

BLAST CABINET METERING VALVE Abrasive Sand Media Blasting Harbor Freight Upgrade | eBay

I understand the difference, Bulldog. I modified my home made Scat cabinet per their instructions. I built mine 20 years ago from their plans. My cabinet has a funnel type trap at the bottom of it. I tried putting my pick up tube at the bottom of the funnel. No good, as the moisture went to the bottom of the collected abrasive it was standing. That's were the moisture collected, too. Depending on how much media you use(I use 50 lbs of 80 grit aluminum oxide), I hard mounted my pick up tube about 3 inches from the bottom of the funnel. I use an old A/C filter with a valve to control how the media is sucked up. I also use a cheap HF filter to supply the air to the cabinet. It might sound strange, but I light my cabinet with an old 150 watt incandescent bulb, which helps dry out the media while blasting. I filter the air with my Craftsman vacuum through another port. It might sound cheesy, but it's served me well over the years. I'll send pictures, if you'd like. Paul.

I'd love to see some pictures. But that's one of the purposes behind moving the pickup to the bottom. You only end up need like a cup or two of abrasive. That's one thing that aids moisture collection is having to use so much.

I was looking at this one for mine. Haven't needed the cabinet in awhile so I haven't been frustrated in awhile...lol

BLAST CABINET METERING VALVE Abrasive Sand Media Blasting Harbor Freight Upgrade | eBay

If you want to buy something ready to go, get it here. It's a lot cheaper. Replace that plastic plug on the bottom with a metal one.

Sandblasting Supplies & Sandblasting Parts | Indianapolis, Indiana | IDS Blast

I bought this one off Ebay.

View attachment 1715751538 BLAST CABINET METERING VALVE HARBOR FREIGHT SANDBLASTING METERING MEDIA VALVE | eBay

I think it does help with the delivery of blasting media. My issue is that the slope on the floor of my blaster is shallow, so the media doesn't funnel very well into the bottom hole.

But, I would say it does help. Just be prepared to make some mods to your blast cabinet.

Yeah, that's what I'm talkin about. I'm going to make one I believe.

80fbody

Well-Known Member

Sweet. Thanks.

Cuda416

Well-Known Member

I did it to mine and in my opinion, it's one of the best things you can do aside from a foot pedal control. Mine looks very much like the one shown above available from fleabay. Biggest problem I have is ridge on the inside edge of my cabinet collects media. Someday I'll fix that but I've got a bunch of other stuff ahead of it on the list.

gzig5

Well-Known Member

I built a version of this design and it was a significant improvement for my HF cabinet. I have the smaller tabletop version cabinet without a stand and I had to add some feet to raise it up, but it was absolutely worth the effort.I bought this one off Ebay.

View attachment 1715751538 BLAST CABINET METERING VALVE HARBOR FREIGHT SANDBLASTING METERING MEDIA VALVE | eBay

I think it does help with the delivery of blasting media. My issue is that the slope on the floor of my blaster is shallow, so the media doesn't funnel very well into the bottom hole.

But, I would say it does help. Just be prepared to make some mods to your blast cabinet.

check out you tube on rays garage. very interesting article using hf blast cabinet and tacoma company parts. i talked to mike at tacoma company(owner, i have his cell number rusty). after you see the video's and take to him, it makes sense. i am going to buy some of the things he has on the list. i have an oversize cat blast cabinet

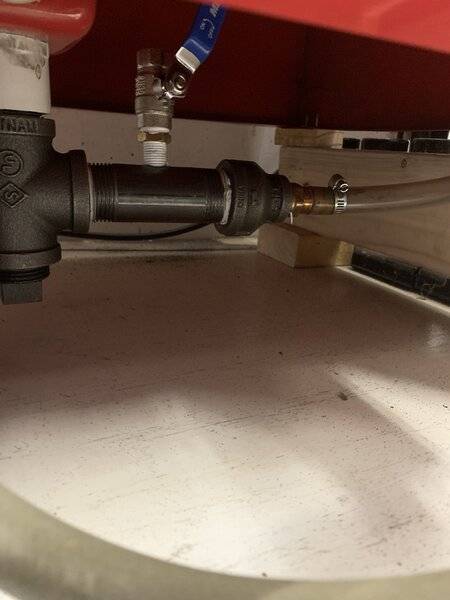

Well I bought all the stuff to make one and did. I am thoroughly fuckin unimpressed. It really worked better before, which wasn't very good. I'm just gonna scrap this damned blaster. I could use the shop space anyway. Here's what I made.

I think I might have found the trouble. The blasting gun has a very small amount of suction going on, but I don't know how to remedy that. I did just get a new set of tips. There were small, medium and large. I got the small thinking that would conserve more air. Could that be affecting the suction to the pickup hose? Yall give me some help here. I'm bout pissed off with all this.

Cuda416

Well-Known Member

I think I might have found the trouble. The blasting gun has a very small amount of suction going on, but I don't know how to remedy that. I did just get a new set of tips. There were small, medium and large. I got the small thinking that would conserve more air. Could that be affecting the suction to the pickup hose? Yall give me some help here. I'm bout pissed off with all this.

Hey man, if you look at the example from yesterday, the pipe is pretty thick. I think mine was 1-1/2". Also, moisture will mess any of these things up so I put a cheap *** moisture trap from HF on mine. I'll be happy to take mine off and show you all the bits.

A HUGE problem I had was getting thing stuck down in the media itself. That's the one downside is that every little thing will drop down into the system and make it's way to your gun.

I'm telling your brother, this works and works WELL.

gzig5

Well-Known Member

How big is the black hose going to the gun? I think mine is at least 1/2". That pipe nipple the hose is clamped to is a restriction too. I went with the thinnest brass nipple I could find.

I don't think the feed will compensate for a crappy gun, but it should provide a more consistent supply of media. Mine went from cutting out all the time to a nice consistent flow. I'll try to snap a pic this afternoon.

I don't think the feed will compensate for a crappy gun, but it should provide a more consistent supply of media. Mine went from cutting out all the time to a nice consistent flow. I'll try to snap a pic this afternoon.

gzig5

Well-Known Member

Correction... I used either a 5/8 or 1/2 id feed hose but couldn't find an appropriate nipple so I made one from 1/2" copper pipe stub soldered into a threaded bushing. No restriction there.

How big is the black hose going to the gun? I think mine is at least 1/2". That pipe nipple the hose is clamped to is a restriction too. I went with the thinnest brass nipple I could find.

I don't think the feed will compensate for a crappy gun, but it should provide a more consistent supply of media. Mine went from cutting out all the time to a nice consistent flow. I'll try to snap a pic this afternoon.

5/8 heater hose. The nipple on my gun is part of the gun.

Correction... I used either a 5/8 or 1/2 id feed hose but couldn't find an appropriate nipple so I made one from 1/2" copper pipe stub soldered into a threaded bushing. No restriction there.

View attachment 1715751921

Yeah I need to make mine like that. Mine has a lot more places for blockages and restrictions. I just LOATHE going to the local hardware store, because I know NOTHING about plumbing stuff and the bad thing is everybody there knows less than I do. dumbasses.

Please keep in mind the ceramic tips wear quickly with aluminum oxide. I switched to a carbide tip. They last much longer, with less pressure loss.

Please keep in mind the ceramic tips wear quickly with aluminum oxide. I switched to a carbide tip. They last much longer, with less pressure loss.

I just got steel ones. I don't have the coin for carbide right now. 55 bucks a piece. Caint do that right now.

vitamindart

Well-Known Member

we have an old eastwood blast cabinet that worked sub par. dad put a 5 gallon bucket under in and left the drain plug out of the bottom of the trap. stuffed the pick up hose in the bucket. he said the thing has never worked better.

-