Pulley-mounted crank trigger w/stock Magnum EFI - trigger notches?

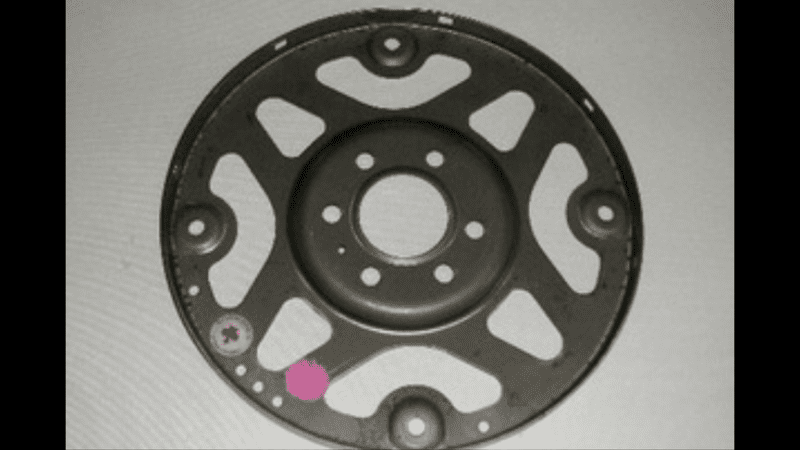

Windows (8 of them) can be seen around the outer diameter.

Thanks for chiming In. I knew you’d have good info to share. These don’t trigger off of a tab though. The wheel is solid and a window passes the sensor to trigger it.

Windows (8 of them) can be seen around the outer diameter.