Clear coat or not

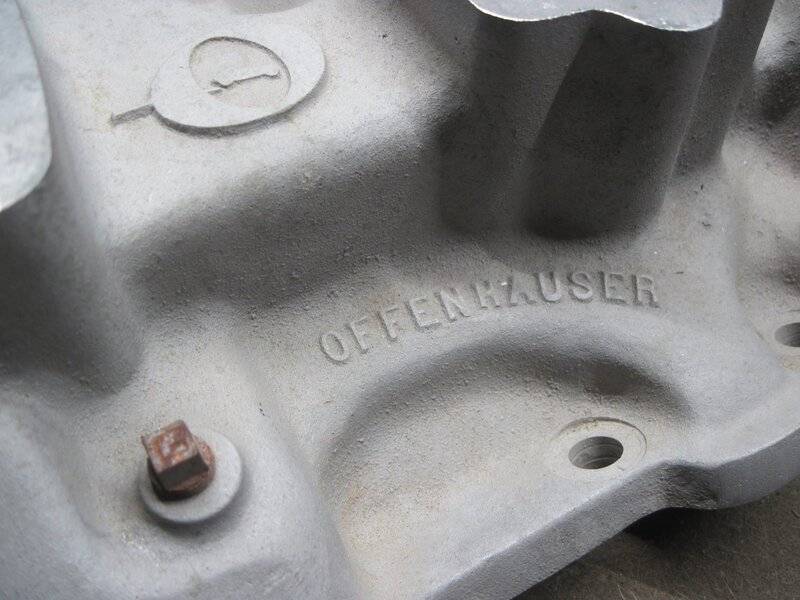

Not to be argumentative pish, but when it's done right powder coating is only a few mils thick. It will smooth the surface and make it more uniform to some degree but pitting, divots and part numbers will all still show.

It's for that reason that I focus most of my labor on bodywork rather than excessive amounts of powder. Most shops merely blast and color what you present as is; in my opinion, there's no point in making it pretty if the metal substrate looks like *** to start with.

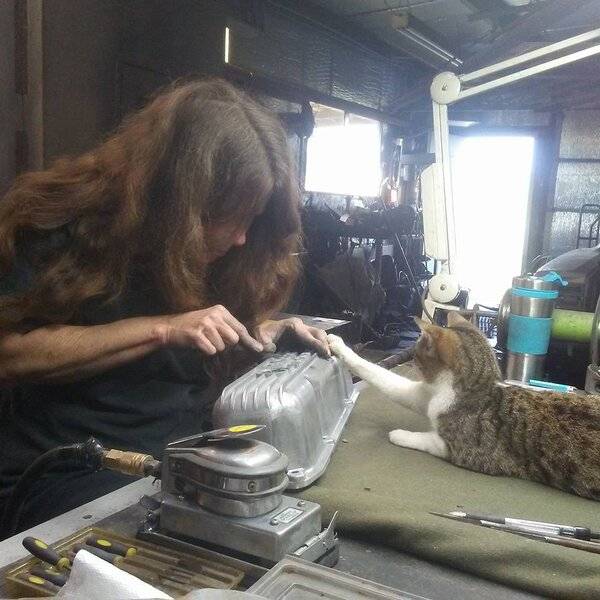

Rich just sent me this pic a few days ago. His intake was restored almost ten years ago.

"Hi there. Hey, remember my tri power you did? Everybody loves it on this Model A!"

Magnesium parts are even worse when it comes to casting "quality," or lack of. Extreme cases need high temp filler in addition to lots of metal work if you want decent results.

Not to be argumentative pish, but when it's done right powder coating is only a few mils thick. It will smooth the surface and make it more uniform to some degree but pitting, divots and part numbers will all still show.

It's for that reason that I focus most of my labor on bodywork rather than excessive amounts of powder. Most shops merely blast and color what you present as is; in my opinion, there's no point in making it pretty if the metal substrate looks like *** to start with.

Rich just sent me this pic a few days ago. His intake was restored almost ten years ago.

"Hi there. Hey, remember my tri power you did? Everybody loves it on this Model A!"

Magnesium parts are even worse when it comes to casting "quality," or lack of. Extreme cases need high temp filler in addition to lots of metal work if you want decent results.