Cluster Woes

While answers above are technically correct as far as they go................thread these problems in an "end to end" manner. THINK about where it starts, where it goes, where it ends, and what happens in between

For example, oil lamp

MUST have correct sender. Gauge type and warning lamp senders are different...........there is a connector on the sender wire somewhat subject to poor connection (general statement, any terminal can fail)

Bulkhead feed through terminal. This can corrode, fail, poor connection

Harness connector at the cluster pc board THESE ARE A BIGGIE. These pins on the pc bard are "riveted" and can work loose / corrode. Solder them to the pc board traces

Lamp sockets.........these have spring fingers which make contact with the PC board traces. Clean the traces with an abrasive eraser. If you don't have, maybe something like REALLY fine sandpaper. Clean and bend the socket contacts for better contact, clean the inside where the bulb fits or replace socket. Check the lamp, make certain it works or replace. Is the lamp shell and contact clean?

Power goes through the lamp and back to a common point on the cluster where it gets power from the ignition switch so THAT must be working, and that is yet another possiblity of a bad pin on the PC board

GENERAL PROBLEMS with cluster and I would check all of them while it's out of the dash

1...As mentioned, pc board pins, solder them

2...The IVR/ regulator for the gauges plugs in on a non-Ralley dash, and the contact fingers can lose contact with the board traces. Solder jumper across from the contact fingers to the traces

3....Gauge studs have "fake" nuts. Consider replacing, and loosen/ tighten these nuts several times to 'scrub' the board clean and make good contact

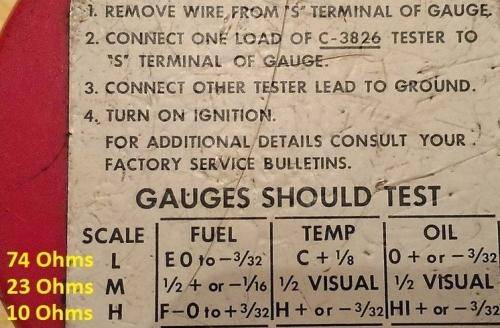

4....Consider checking the gauges for accuracy. You can roust up resistances to check gauges, the infamous gauge tester photo shows resistances.

5...Consider replacing the gauge IVR with a solid state one form RTE or someone similar

6....Check over the ammeter / bulkhead connector condition. EVEN IF YOU do not bypass the ammeter, READ this article so you understand the how and why

Catalog

While answers above are technically correct as far as they go................thread these problems in an "end to end" manner. THINK about where it starts, where it goes, where it ends, and what happens in between

For example, oil lamp

MUST have correct sender. Gauge type and warning lamp senders are different...........there is a connector on the sender wire somewhat subject to poor connection (general statement, any terminal can fail)

Bulkhead feed through terminal. This can corrode, fail, poor connection

Harness connector at the cluster pc board THESE ARE A BIGGIE. These pins on the pc bard are "riveted" and can work loose / corrode. Solder them to the pc board traces

Lamp sockets.........these have spring fingers which make contact with the PC board traces. Clean the traces with an abrasive eraser. If you don't have, maybe something like REALLY fine sandpaper. Clean and bend the socket contacts for better contact, clean the inside where the bulb fits or replace socket. Check the lamp, make certain it works or replace. Is the lamp shell and contact clean?

Power goes through the lamp and back to a common point on the cluster where it gets power from the ignition switch so THAT must be working, and that is yet another possiblity of a bad pin on the PC board

GENERAL PROBLEMS with cluster and I would check all of them while it's out of the dash

1...As mentioned, pc board pins, solder them

2...The IVR/ regulator for the gauges plugs in on a non-Ralley dash, and the contact fingers can lose contact with the board traces. Solder jumper across from the contact fingers to the traces

3....Gauge studs have "fake" nuts. Consider replacing, and loosen/ tighten these nuts several times to 'scrub' the board clean and make good contact

4....Consider checking the gauges for accuracy. You can roust up resistances to check gauges, the infamous gauge tester photo shows resistances.

5...Consider replacing the gauge IVR with a solid state one form RTE or someone similar

6....Check over the ammeter / bulkhead connector condition. EVEN IF YOU do not bypass the ammeter, READ this article so you understand the how and why

Catalog