How much does temperature affect motor?

Well I sure aint Jesus but I'll try again to get you on the right path.

So yes, I think the wrong path. Dont feel bad - you've got lots of company with those who have been there and done that.

Check if the fuel pressure is the same when hot and the engine is having issues. Next then check fuel level. You might have to shut it off if the engine is shaking alot. Then do a quick check and be prepared for spillage. First, look down the carb to see if its dry or wet. It ought to be dry. If its wet, then expect the fuel level to be high.

I'm guess you mean the exhaust smells rich with partially burned fuel; but possibly you mean you actually are smelling raw gas.

OK. So here's one of the places you went went off track, but as it happens I think you ended up OK.

Unless something is wrong, the primary jets should have virtually no effect on fuel metering at idle and low throttle.

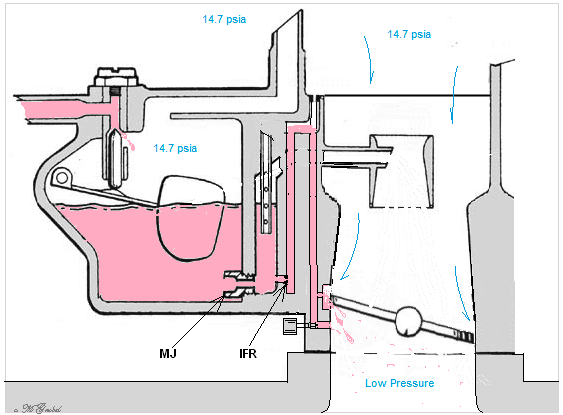

The low speed circuit feeds off of the high speed circuit. The low speed circuit has its own fuel restriction that is much smaller than the jet. So unless the main jet is very small, the low speed restriction (usually called the idle feed restriction or IFR) controls how much fuel goes into the low speed circuit.

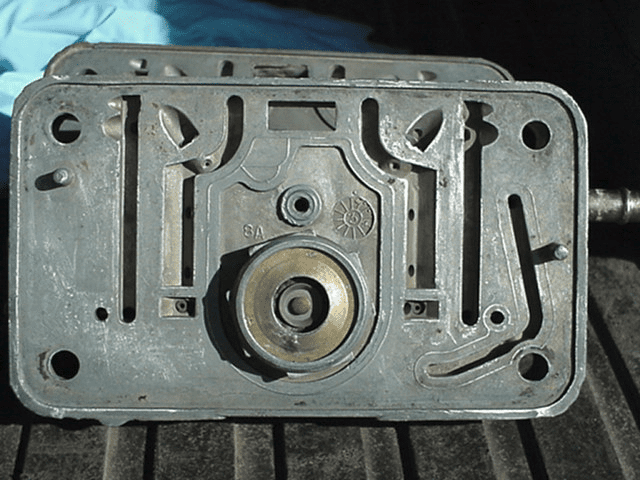

You can see the IFR on this 3310-2 primary metering block.

Changes to main jet should be very noticible cruising at interstate speeds and when you're got your foot deeper in the pedal.

I think you ended up OK because 73 primary main jet is closer to the original specs.

As I metioned last June, the 3310-1 came with 72 primary main jet (PMJ) and 76 secondary main jets. 10.5 Power Valve in the primary and 8.5 PV in the secondary.

Let me point you to some background on how these carbs work. That way you're not dependent on random voices on the internet all claiming they have the true path to tuning bliss.

IMO the best introduction to the principles is the first chapters of Urich and Fisher's Holley Carburetors and Manifolds. Any edition will do, no reason to pay for the latest edition with fuel injection, etc. There is also a smaller version just on the 4150/60 models which has much of the same explanation of the circuits.

Chrysler's Master Tech series covers the same material pretty well.

Here's a direct link Carburetion Fundamentals & Facts (Session 273) from the Master Technician's Service Conference

or if you prefer pdf format, go to mymopar.com and look under Master Technician's Conference 1970, Carburation Fundementals and Facts.

Let me see if I can clarify a few things.

If you set the timing to be 15* BTDC at 850-900 rpm, then the timing is likely not stable.

On most Chrysler distributors the timing advances very quickly above idle speed.

(a couple of examples here: Another Boggie One)

If the distributor was intended for an engine idling at 700 rpm, and you set the timing at 900 rpm, then your measurement is not the initial timing. Its the base timing plus the amount added by the centrifical advance.

So initial timing is something less than 15*. How much less depends on the distributor setup (internal).

A motorhome 360 ought to idle relatively low rpm.

The hesitation you mention is very possibly due to the throttle position being too far open or too far closed at idle.

At idle the primary transfer ports should be showing between .020 and .040" below the throttle plate.

If you have to adjust outside that range, increase the timing or reduce it to get the idle rpm to drop or increase.

It should idle below 800 rpm.

Urich explains why in this sidebar I posted here. Your engine is not radical and there is no reason the throttle plates should have to be modified.

Well hopefully now you'll head in the right direction.

Get the idle and off idle first.

After adjusting timing or throttle position, then check and readjust all the other things.

The goal is least drop in rpm or vacuum when going into gear at idle.

One big clue your in the ballpark with the throttle position at idle is whetehr turning the idle mix screws provides adjustment. if you can screw them all the way in with no effect, then throttle is way too far open.

If the carb is off the engine, you can measure and write down how many turns of the idle speed screw open the throttle from .020 to .040 showing on the transfer slot. Big time saver.

Good luck.

Well I sure aint Jesus but I'll try again to get you on the right path.

So yes, I think the wrong path. Dont feel bad - you've got lots of company with those who have been there and done that.

Fuel level and pressure. Great!

Check if the fuel pressure is the same when hot and the engine is having issues. Next then check fuel level. You might have to shut it off if the engine is shaking alot. Then do a quick check and be prepared for spillage. First, look down the carb to see if its dry or wet. It ought to be dry. If its wet, then expect the fuel level to be high.

When you write dumping raw fuel that sounds like fuel dripping out the boosters leaking.

I'm guess you mean the exhaust smells rich with partially burned fuel; but possibly you mean you actually are smelling raw gas.

OK. So here's one of the places you went went off track, but as it happens I think you ended up OK.

Unless something is wrong, the primary jets should have virtually no effect on fuel metering at idle and low throttle.

The low speed circuit feeds off of the high speed circuit. The low speed circuit has its own fuel restriction that is much smaller than the jet. So unless the main jet is very small, the low speed restriction (usually called the idle feed restriction or IFR) controls how much fuel goes into the low speed circuit.

You can see the IFR on this 3310-2 primary metering block.

Changes to main jet should be very noticible cruising at interstate speeds and when you're got your foot deeper in the pedal.

I think you ended up OK because 73 primary main jet is closer to the original specs.

As I metioned last June, the 3310-1 came with 72 primary main jet (PMJ) and 76 secondary main jets. 10.5 Power Valve in the primary and 8.5 PV in the secondary.

Let me point you to some background on how these carbs work. That way you're not dependent on random voices on the internet all claiming they have the true path to tuning bliss.

IMO the best introduction to the principles is the first chapters of Urich and Fisher's Holley Carburetors and Manifolds. Any edition will do, no reason to pay for the latest edition with fuel injection, etc. There is also a smaller version just on the 4150/60 models which has much of the same explanation of the circuits.

Chrysler's Master Tech series covers the same material pretty well.

Here's a direct link Carburetion Fundamentals & Facts (Session 273) from the Master Technician's Service Conference

or if you prefer pdf format, go to mymopar.com and look under Master Technician's Conference 1970, Carburation Fundementals and Facts.

We went through this last time but perhaps we weren't clear or you got distracted by one of the posts.

Let me see if I can clarify a few things.

If you set the timing to be 15* BTDC at 850-900 rpm, then the timing is likely not stable.

On most Chrysler distributors the timing advances very quickly above idle speed.

(a couple of examples here: Another Boggie One)

If the distributor was intended for an engine idling at 700 rpm, and you set the timing at 900 rpm, then your measurement is not the initial timing. Its the base timing plus the amount added by the centrifical advance.

So initial timing is something less than 15*. How much less depends on the distributor setup (internal).

A motorhome 360 ought to idle relatively low rpm.

The hesitation you mention is very possibly due to the throttle position being too far open or too far closed at idle.

At idle the primary transfer ports should be showing between .020 and .040" below the throttle plate.

If you have to adjust outside that range, increase the timing or reduce it to get the idle rpm to drop or increase.

It should idle below 800 rpm.

Urich explains why in this sidebar I posted here. Your engine is not radical and there is no reason the throttle plates should have to be modified.

Well hopefully now you'll head in the right direction.

Get the idle and off idle first.

After adjusting timing or throttle position, then check and readjust all the other things.

The goal is least drop in rpm or vacuum when going into gear at idle.

One big clue your in the ballpark with the throttle position at idle is whetehr turning the idle mix screws provides adjustment. if you can screw them all the way in with no effect, then throttle is way too far open.

If the carb is off the engine, you can measure and write down how many turns of the idle speed screw open the throttle from .020 to .040 showing on the transfer slot. Big time saver.

Good luck.