It's like eating that elephant, one bite at a time. When & where are you going to run it on its maiden voyage?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1972 Dodge Colt

- Thread starter Hyper_pak

- Start date

-

Hyper_pak

Old School Chrysler Fan

I might get it over to Ennis to run through tech.

But I am aiming for Clay City in Sept.

But I am aiming for Clay City in Sept.

That's too far for me to go since the wife is still working.

I got an email from Hoosier today.

What is your shipping address to send you a new tube?

WooHoo!

Dang skippy!

Push rods are here, maybe tomorrow they will go in.

Worked on some sheet metal inside and mounted shifter.

Half the brake system tightened and tweaked.

If all these parts stay installed and working it will be started soon.

Really starting to look like a race car now and not just a pile of parts.

View attachment 1715774028 View attachment 1715774029

Looks very professional, so we all know I ain't involved. lol

Hyper_pak

Old School Chrysler Fan

You do good work Rob.Looks very professional, so we all know I ain't involved. lol

justinp61

Well-Known Member

- Joined

- May 15, 2009

- Messages

- 3,064

- Reaction score

- 4,051

I might get it over to Ennis to run through tech.

But I am aiming for Clay City in Sept.

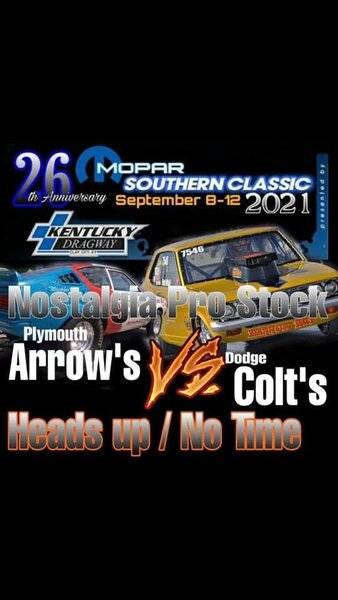

View attachment 1715774035

While your up this way you should swing the through Bowling Green the next weekend for the Moparty.

Hyper_pak

Old School Chrysler Fan

I should do that, but to tell you the truth, Clay City has been the goal for 9 Months.

I am retired, but this thing has become a mill stone around my neck.

It's something about my makeup, and I have been working non stop to get it ready.

When the race weekend is over I am going to breathe big sigh of relief.

This hobby is supposed to be fun and for a few months it hasn't been a lot of fun.

It will be good to have it to a certain point and just improve it slowly.

Today was brakes, fuel, electrical, cleanup, etc.

Not a lot of any of it, just a little of all of it.

Joe Liberty and one of the first slick shift A-833 transmissions.

I am retired, but this thing has become a mill stone around my neck.

It's something about my makeup, and I have been working non stop to get it ready.

When the race weekend is over I am going to breathe big sigh of relief.

This hobby is supposed to be fun and for a few months it hasn't been a lot of fun.

It will be good to have it to a certain point and just improve it slowly.

Today was brakes, fuel, electrical, cleanup, etc.

Not a lot of any of it, just a little of all of it.

Joe Liberty and one of the first slick shift A-833 transmissions.

i get that. and then, when something else gets in the way of working on it, all you can think about is getting back to itI am retired, but this thing has become a mill stone around my neck.

It's something about my makeup, and I have been working non stop to get it ready.

When the race weekend is over I am going to breathe big sigh of relief.

This hobby is supposed to be fun and for a few months it hasn't been a lot of fun.

It will be good to have it to a certain point and just improve it slowly.

Hyper_pak

Old School Chrysler Fan

Push rods are in and the rockers are adjusted.

All that looks good.

Worked a few hours on the hydraulic clutch.

Had a ***** bleeding it, but I got it eventually.

There are quite a few little things that have me concerned.

Pedal ratio.

Bearing travel.

Durability of the original master cylinder.

After I get a little more stuff working, I think some questions will be answered.

All that looks good.

Worked a few hours on the hydraulic clutch.

Had a ***** bleeding it, but I got it eventually.

There are quite a few little things that have me concerned.

Pedal ratio.

Bearing travel.

Durability of the original master cylinder.

After I get a little more stuff working, I think some questions will be answered.

abdywgn

dismantler

It looks like a Mr.Gasket vertical gate but what are the pieces on the side cover?I should do that, but to tell you the truth, Clay City has been the goal for 9 Months.

I am retired, but this thing has become a mill stone around my neck.

It's something about my makeup, and I have been working non stop to get it ready.

When the race weekend is over I am going to breathe big sigh of relief.

This hobby is supposed to be fun and for a few months it hasn't been a lot of fun.

It will be good to have it to a certain point and just improve it slowly.

Today was brakes, fuel, electrical, cleanup, etc.

Not a lot of any of it, just a little of all of it.

Joe Liberty and one of the first slick shift A-833 transmissions.

View attachment 1715774455

Hyper_pak

Old School Chrysler Fan

Not sure on the Liberty picture.

I know there were a lot of different experiments with shifters.

Can't seem to get enough travel on the Hydraulic Release Bearing.

It moves a good way but not enough to release the pinch on the disk.

Going to try longer pivot arm first.

Started bleeding the brakes, got the master bled.

I had a problem with the rear disk rotors, they would not clear the studs.

I spoke with Strange and they said to use the large slots in the rotor hat.

I never liked that answer, so today I did a little fitting with the small slots.

Got both left and right to fit like they are supposed to.

Maybe the old axles had a little more tolerances than the new rotors.

If you look at this picture you see the small slots and the large slots.

This picture is before the fix.

Also worked on the electrical system.

I have an Auto Rod switch panel and after wringing it, I found a bad switch.

So I have a new switch on order.

Also need to splice about half the wires to fit the changes to the car.

I had a bunch of wire, I thought was 14 gage, turned out it's 16 gage.

It will work on a couple of circuits, not on all.

I know there were a lot of different experiments with shifters.

Can't seem to get enough travel on the Hydraulic Release Bearing.

It moves a good way but not enough to release the pinch on the disk.

Going to try longer pivot arm first.

Started bleeding the brakes, got the master bled.

I had a problem with the rear disk rotors, they would not clear the studs.

I spoke with Strange and they said to use the large slots in the rotor hat.

I never liked that answer, so today I did a little fitting with the small slots.

Got both left and right to fit like they are supposed to.

Maybe the old axles had a little more tolerances than the new rotors.

If you look at this picture you see the small slots and the large slots.

This picture is before the fix.

Also worked on the electrical system.

I have an Auto Rod switch panel and after wringing it, I found a bad switch.

So I have a new switch on order.

Also need to splice about half the wires to fit the changes to the car.

I had a bunch of wire, I thought was 14 gage, turned out it's 16 gage.

It will work on a couple of circuits, not on all.

Hyper_pak

Old School Chrysler Fan

Brakes are bled.

Had a few leaks, but getting smarter.

Used drop cloths, and cardboard under the connection spots.

As I worked the pedal when I heard or saw a little drip I could get right on it.

I really hate drips and leaks on the concrete.

Back brakes are great, fronts are ok, but those old calipers bled real slow.

But I got good lock on all 4 corners and clean release.

I will dial it in as soon as it starts moving with the proportional valve.

Clutch is still no go.

The S&W pedals have a ratio of 3.6 on lower hole

The top hole is at 5.7.

What I have read is a ratio around 5 to 7 is ballpark.

Problem is the top hole is to close to the floor.

But I am not sure that using this Borg and Beck style PP might be the problem.

This is a new D.C. green cover unit and I do remember lots of pedal pressure.

I have not seen any note saying only a diaphragm style PP will work.

Lokar bracket on carb, will fit the new cable tomorrow.

Had a few leaks, but getting smarter.

Used drop cloths, and cardboard under the connection spots.

As I worked the pedal when I heard or saw a little drip I could get right on it.

I really hate drips and leaks on the concrete.

Back brakes are great, fronts are ok, but those old calipers bled real slow.

But I got good lock on all 4 corners and clean release.

I will dial it in as soon as it starts moving with the proportional valve.

Clutch is still no go.

The S&W pedals have a ratio of 3.6 on lower hole

The top hole is at 5.7.

What I have read is a ratio around 5 to 7 is ballpark.

Problem is the top hole is to close to the floor.

But I am not sure that using this Borg and Beck style PP might be the problem.

This is a new D.C. green cover unit and I do remember lots of pedal pressure.

I have not seen any note saying only a diaphragm style PP will work.

Lokar bracket on carb, will fit the new cable tomorrow.

Hey Stan,

Finally able to log in and post. Car is looking great. Love the polished Bogarts. What size tires on the rear? Too bad we live so far apart would be great to lend a hand, Can't wait for its first run.

Herb

Finally able to log in and post. Car is looking great. Love the polished Bogarts. What size tires on the rear? Too bad we live so far apart would be great to lend a hand, Can't wait for its first run.

Herb

Hyper_pak

Old School Chrysler Fan

Hey Herb, glad your back on the forum.

The rears are 29 x 12 x 15.

They measure a little larger on Diameter but a LOT smaller than what was on the car.

Still on jack stands so I want to see how it sits now.

Clutch is the problem now.

The rears are 29 x 12 x 15.

They measure a little larger on Diameter but a LOT smaller than what was on the car.

Still on jack stands so I want to see how it sits now.

Clutch is the problem now.

Hyper_pak

Old School Chrysler Fan

Might have the clutch working.

Looks like the master cylinder is working fine.

When I sat in the car and mashed the pedal I could turn the output shaft.

Adjusting pedal ratio now to make less pedal effort.

I did speak with American Powertrain today.

I asked about my 3 finger Borg and Beck PP.

The only thing they print is "compatible with diaphragm clutches."

Tech line says the TOB can press through the 3 fingers and get stuck.

The bearing is the same size as the factory bearing, how can it go pass the fingers?

I can't imagine how far over center that would be.

I also figured out the tube issue.

The valve stem hole is drilled for tubeless tires.

I spoke with them about it being a drag car and slicks.

What happened was the valve stem was locked down 2 inches on one side.

Then it has to roll over the other 10 inches into the tire and it caused the stem to detach.

When I spoke to them they said they didn't realize I was using a tube.

Thank you Hoosier for covering my problem, not theirs.

Looks like now I will put big valve stems in and run tubeless.

Looks like the master cylinder is working fine.

When I sat in the car and mashed the pedal I could turn the output shaft.

Adjusting pedal ratio now to make less pedal effort.

I did speak with American Powertrain today.

I asked about my 3 finger Borg and Beck PP.

The only thing they print is "compatible with diaphragm clutches."

Tech line says the TOB can press through the 3 fingers and get stuck.

The bearing is the same size as the factory bearing, how can it go pass the fingers?

I can't imagine how far over center that would be.

I also figured out the tube issue.

The valve stem hole is drilled for tubeless tires.

I spoke with them about it being a drag car and slicks.

What happened was the valve stem was locked down 2 inches on one side.

Then it has to roll over the other 10 inches into the tire and it caused the stem to detach.

When I spoke to them they said they didn't realize I was using a tube.

Thank you Hoosier for covering my problem, not theirs.

Looks like now I will put big valve stems in and run tubeless.

Hyper_pak

Old School Chrysler Fan

Thanks Herb, I am sending the wheels back this week.

They are going to replace both front half of the rims and put the stem in a central location.

When they get back I will run them tubless, but if I drop pressure I can install the tubes.

On your car, where is your master cylinder?

If its on the firewall the kit cylinder will work and you can buy a system.

Doing research there are quite a few companies that make them.

I really want to run a Lenco, but this was all I could afford right now.

Driveshaft back and installed. Feels good to have that in!

They are going to replace both front half of the rims and put the stem in a central location.

When they get back I will run them tubless, but if I drop pressure I can install the tubes.

On your car, where is your master cylinder?

If its on the firewall the kit cylinder will work and you can buy a system.

Doing research there are quite a few companies that make them.

I really want to run a Lenco, but this was all I could afford right now.

Driveshaft back and installed. Feels good to have that in!

Thanks for the info. My brake master is underneath like yours but it's behind my seat. No clutch master or pedal. That's one of things that I am debating. I would have to redo the brake setup to make room for a clutch pedal. Also the money thing, I would like a GForce 101A but it's pricey.

If I had your car I would get a Lenco also and don't forget the Hurst Lighting Rod shifters.

If I had your car I would get a Lenco also and don't forget the Hurst Lighting Rod shifters.

Hyper_pak

Old School Chrysler Fan

Wheels are back to Bogart.

Kinda pisses me off, but I was stupid and didn't catch the tube offset issue.

Got to pay for education.

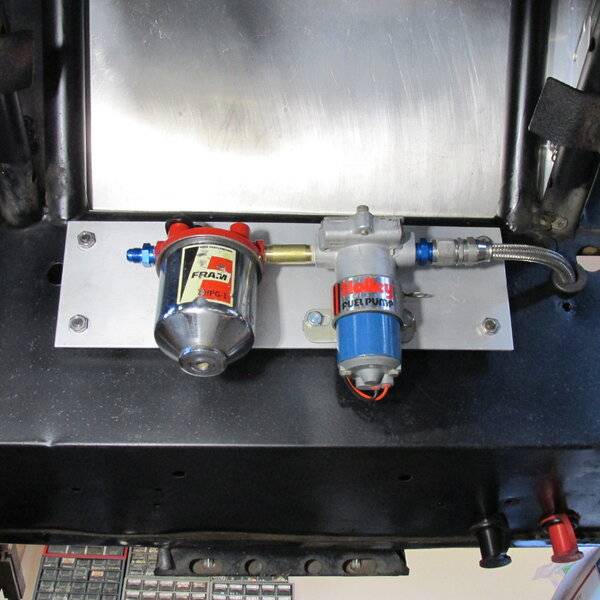

Worked fuel system today.

Shock mounted Mounting plate, fuel pump and filter mounted in the rear.

These are the parts that were on the Colt when I got it.

Fuel tank to fuel pump AN-8 hose built and installed.

I have the AN-6 hose to the front made and will start that running tomorrow.

All Stainless Steel Teflon hose and Aeroquip fittings.

Kinda pisses me off, but I was stupid and didn't catch the tube offset issue.

Got to pay for education.

Worked fuel system today.

Shock mounted Mounting plate, fuel pump and filter mounted in the rear.

These are the parts that were on the Colt when I got it.

Fuel tank to fuel pump AN-8 hose built and installed.

I have the AN-6 hose to the front made and will start that running tomorrow.

All Stainless Steel Teflon hose and Aeroquip fittings.

383Duster

Well-Known Member

This would make a different slant 6 race car…. Gonna be auctioned in October

https://barnfinds.com/hoard-of-mopa...LKLZfPDT-d3h9ll2QF3XTaNCtVfR3pDWoYJI50jx_yyvE

slantracer

Well-Known Member

That wagon would be great for Stan!

The Colt is about done and Stan has already built a show winning Lancer wagon.

So this wagon should build fast and would be easy since he has done one.

I don't think it would be caught by a tech guy, but is your driveshaft loop with 6" of the u-joint? I know there is no way the driveshaft could come out but if a tech guy is having a bad day it could cause a problem. My 2 cents worth.

The Colt is about done and Stan has already built a show winning Lancer wagon.

So this wagon should build fast and would be easy since he has done one.

I don't think it would be caught by a tech guy, but is your driveshaft loop with 6" of the u-joint? I know there is no way the driveshaft could come out but if a tech guy is having a bad day it could cause a problem. My 2 cents worth.

Hyper_pak

Old School Chrysler Fan

It's further than 6 inches.

Also reading the rule book it says no flexible steering shafts.

So I am way far behind on fixing stuff.

Will says tech guys are so happy to see a six powered car that they stop looking.

I guess they are sick of ls powered shix-boxes.

Truth be known, I think YOU are jonesin for the Lancer Wagon.

I do have an NOS tail light assembly. It's a start.

Also reading the rule book it says no flexible steering shafts.

So I am way far behind on fixing stuff.

Will says tech guys are so happy to see a six powered car that they stop looking.

I guess they are sick of ls powered shix-boxes.

Truth be known, I think YOU are jonesin for the Lancer Wagon.

I do have an NOS tail light assembly. It's a start.

Hyper_pak

Old School Chrysler Fan

Craig, you want to go half in on the wagon with me?

-