Subframe connectors needed or not?

Weld In Your Own Frame Connectors

"Weld In Your Own Frame Connectors

Frame connectors are an excellent way to stiffen the body of your old unitized Mopar. However, dont think it's only for race cars...Theres a noticable difference in handling and steering on the street after adding them. These old bodies flex much more than you'd think. Some basic welding skills are all thats required, or you could get everything fit and ready, then drive the car to a welding shop where someone could weld them in for you in about an hour. You wont be dissappointed with the results.

The connectors shown above were home-made from 2x3x.125 mild steel and they slide right over the rear frame rails.

The connectors shown above were home-made from 2x3x.125 mild steel and they slide right over the rear frame rails.

The plates on the forward end are 2x6x.125 mild steel plate. The length of these bars are 53", but it depends on how much you want to overlap the rear frame rails. Aftermarket weld-in connectors dont over lap at all, but just have an angle cut to butt directly against the leading edge of the rear rails. Thr bars pictured actually go right back to the spring eye boxes for the inboard leaf springs, and have a small slot cut in them at the end to clear the old spring hanger brackets.

Holding the bars up shows that with them lined up with the rear rails they're actually a bit to the outside of the front rails.

Holding the bars up shows that with them lined up with the rear rails they're actually a bit to the outside of the front rails.

Mark the location and clean the weld areas well. Weldable primer or coating is also a good idea as it prevents corrosion in places that arent accessible after the part is installed.

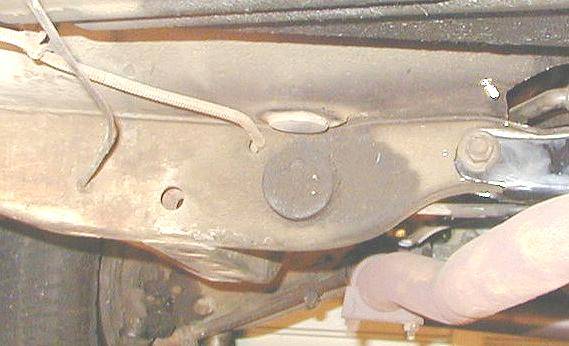

When you fit the driver side, you'll notice the next hurdle. The parking brake cable runs through the frame right where you're connector needs to be. The original hole can be seen in the left picture. The right picture shows the front of the crossmember. Theres a second stamped hole above this. Simply drill through that hole and through the back side of the crossmember. You can also drill a whole new hole off to one side or the other. It's all where you prefer to put it. It just appears cleaner if you use the stamped hole thats there. You must also take care in removing the old grommet that holds the cable in place in the hole. Its bound to be close to the breaking point after 30 years. The photo below shows the new cable location directly above the connector.

A nice clean modification thats undetectable.

.

.

In these two photos, you can just make out the weld line where the connector overlaps the rails. On the left, it actually goes the full length and butts into the spring hanger bracket. The bottom continues right back to meet the lower edge of the spring box. Once you compare these pics to your own car, it will be evident how a few simple cuts will tie in this entire structure in the back.

In these two photos, you can just make out the weld line where the connector overlaps the rails. On the left, it actually goes the full length and butts into the spring hanger bracket. The bottom continues right back to meet the lower edge of the spring box. Once you compare these pics to your own car, it will be evident how a few simple cuts will tie in this entire structure in the back.

Heres the full installation. Your car will now act like its 30 years younger. Also note the new exhaust that took place during these pics. The old Y-pipe can be seen in other pics."

Weld In Your Own Frame Connectors

"Weld In Your Own Frame Connectors

Frame connectors are an excellent way to stiffen the body of your old unitized Mopar. However, dont think it's only for race cars...Theres a noticable difference in handling and steering on the street after adding them. These old bodies flex much more than you'd think. Some basic welding skills are all thats required, or you could get everything fit and ready, then drive the car to a welding shop where someone could weld them in for you in about an hour. You wont be dissappointed with the results.

The plates on the forward end are 2x6x.125 mild steel plate. The length of these bars are 53", but it depends on how much you want to overlap the rear frame rails. Aftermarket weld-in connectors dont over lap at all, but just have an angle cut to butt directly against the leading edge of the rear rails. Thr bars pictured actually go right back to the spring eye boxes for the inboard leaf springs, and have a small slot cut in them at the end to clear the old spring hanger brackets.

Mark the location and clean the weld areas well. Weldable primer or coating is also a good idea as it prevents corrosion in places that arent accessible after the part is installed.

When you fit the driver side, you'll notice the next hurdle. The parking brake cable runs through the frame right where you're connector needs to be. The original hole can be seen in the left picture. The right picture shows the front of the crossmember. Theres a second stamped hole above this. Simply drill through that hole and through the back side of the crossmember. You can also drill a whole new hole off to one side or the other. It's all where you prefer to put it. It just appears cleaner if you use the stamped hole thats there. You must also take care in removing the old grommet that holds the cable in place in the hole. Its bound to be close to the breaking point after 30 years. The photo below shows the new cable location directly above the connector.

A nice clean modification thats undetectable.

Heres the full installation. Your car will now act like its 30 years younger. Also note the new exhaust that took place during these pics. The old Y-pipe can be seen in other pics."