Plenty of rod but I'm maxed out on freeplay. Any more and the bearing will be up against the fingers.can you try a longer threaded rod? I have seen different lengths over the years for Mopars also I have seen rods with welded extensions on them. I am referring to the cutch adjustment rod. actually your pic looks like you have more ajustment on the rod, however you need the free play in there as in the throwout bearing shouldnt spin all the time.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clutch Spring Installed Correctly

- Thread starter blewbyoutobad

- Start date

-

Dartswinger70

Well-Known Member

Yeah that's what it looks like or that's what happens. so you are saying your engine needs to be "forward" for your clutch adjustment to work?Plenty of rod but I'm maxed out on freeplay. Any more and the bearing will be up against the fingers.

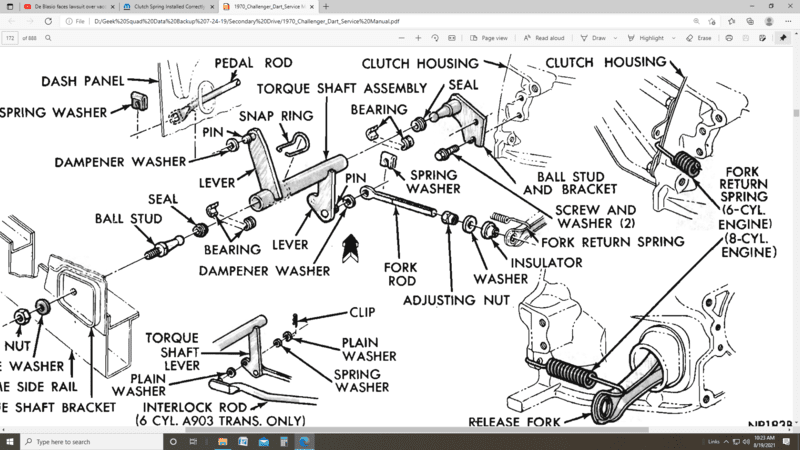

Clearly, something is wrong. The spring in your picture does not hook that way. That little slot in the fork is a hook point, making a tab that would be attached by the z-bar pivot would be the other. Does the RMS mount attach at the engine, or did you use the stock motor mount and that attaches to the RMS mount?

I have this same set up. I do have a Centerforce II diaphragm clutch. I had to do some altering to get it to operate smoothly. Plus, you say the alignment is off on your trans. If that is off, so is your clutch linkage.

Can you get a second pair of eyes to look at it? Your missing something. You can only do so much here.

I have this same set up. I do have a Centerforce II diaphragm clutch. I had to do some altering to get it to operate smoothly. Plus, you say the alignment is off on your trans. If that is off, so is your clutch linkage.

Can you get a second pair of eyes to look at it? Your missing something. You can only do so much here.

Clearly, something is wrong. The spring in your picture does not hook that way. That little slot in the fork is a hook point, making a tab that would be attached by the z-bar pivot would be the other. Does the RMS mount attach at the engine, or did you use the stock motor mount and that attaches to the RMS mount?

I have this same set up. I do have a Centerforce II diaphragm clutch. I had to do some altering to get it to operate smoothly. Plus, you say the alignment is off on your trans. If that is off, so is your clutch linkage.

Can you get a second pair of eyes to look at it? Your missing something. You can only do so much here.

I used all the RMS components. Last night I drilled the bellhousing and attached the spring. Aside from being moved back all the linkage is parallel. I move the z bar ball stud to accommodate for the engine setback. All is parallel and straight. No binding. I will talk to Bill today about that. Heres what I did last night.

No the adjustment and alignment are correct now based on my mods. The engine is moved back becasue of the Reily Motorsports K frame and engine mounts.Yeah that's what it looks like or that's what happens. so you are saying your engine needs to be "forward" for your clutch adjustment to work?

Going for a ride in a few.

Never seen a locking nut used here, on the clutch rod..but OK. But I do see the adjustment nut is *** backwards, the acorn part of the nut should ride in the metal washer, this will help to center the rod and provide a better pivot for rod movement...

The washer does not have a place for the acorn to drop into. Thats why its backward and the double nut. All these parts came from Brewers.Never seen a locking nut used here, on the clutch rod..but OK. But I do see the adjustment nut is *** backwards, the acorn part of the nut should ride in the metal washer, this will help to center the rod and provide a better pivot for rod movement...

I guess I need to call Brewers now.The washer does not have a place for the acorn to drop into. Thats why its backward and the double nut. All these parts came from Brewers.

Dartswinger70

Well-Known Member

How did it drive? did the clutch feel ok?

Trying to get away from the computer so I can go.How did it drive? did the clutch feel ok?

Drives great now, except I dont have 3rd or 4th. I think the linkage came off some how. It was installed according to the book.How did it drive? did the clutch feel ok?

Ok Brewers said the acorn goes against the flat side of the washer. Sure enough it dropped in the hole. So thats fixed. Now on to 3rd and 4th once it cools off.

Here is a pic of what it should look like, if it helps you.

Replaced spring clip on shift rod and everything is working better than before. Smooth with no dragging.

Thanks all for your help.

Thanks all for your help.

-