Project "Chihuahua" '65 Formula S Restoration "Estilo Mexicano"

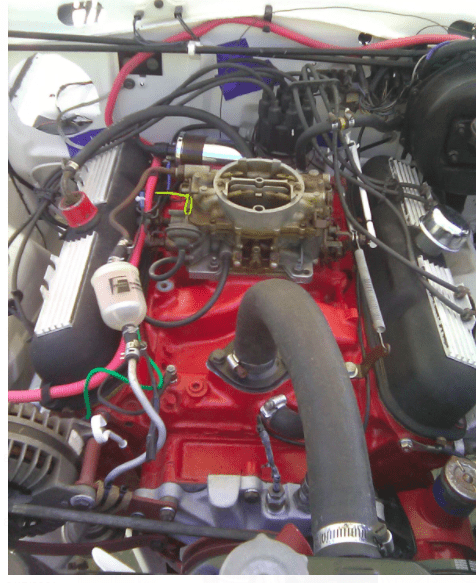

Update: Engine up and running. Now for some good news, the factory 273 Formula S Carter AFB was able to fire up the current 318 without having been rebuilt (again). Choke is wired open (don't have the choke thermostat). Only head pipes installed for now (no x-pipe, mufflers, nor tail pipes). Cold oil pressure is 60-65 PSI (mechanical gauge). With 180 degree thermostat, coolant warms up to 210 while idling at standstill (mechanical gauge). The one-wire alternator is charging 14-plus volts with the old factory style voltage regulator (alternator amp capacity unknown). The single-point distributor provides 10 degrees advance at idle speed. Pumping the accelerator pedal two or three times provides an immediate start-up.

Problems found prior to and after initial fire-up to the previously rebuilt 318 that has been in "storage" for the past three years during the restoration process:

1) Oil pan drain plug dripped slightly after filling the crankcase with oil (Castrol 20W-50). Re-tightened plug. Note: The oil pan was replaced prior to engine installation because the later version 318 oil pan that had been used previously was interfering with the steering link.

2) When I filled the now rebuilt torque flight with fluid for the first time, ATF began to drip (but very slowly) from the very end of the tail shaft where the ball & trunnion driveshaft bolts up. I purchased a new seal (not installed yet).

3) The starter could only be activated with a remote switch connected to the solenoid. The ignition key would not function. No power found under dash past the ammeter. Bypassed the ammeter by securing both ammeter wires together and everything began to work again.

4) Engine could only be started in "park" and not in "neutral". I had to adjust the floor shift selector cable quite a bit to find the correct adjustment.

5) Engine would only run by priming carb. Needed to replace the used mechanical fuel pump (that I had cleaned and painted up nicely).

6) The large 1 3/16th bolt that secures the 90 degree oil filter adaptor was dripping engine oil. Tightening the bolt once with a correct size combination wrench I purchased (cost about twenty bucks) did not stop the drip. Removed the TTI 2 1/2 inch head pipe from that side (for access) and replaced all three gaskets that pertain to the filter adaptor. Oil Leak appears to have stopped.

7) Water pump bolt that also secures the alternator adjusting bracket leaked coolant. Replacing bolt (longer/more threads) with sealant did not solve the leak. Resorted to good old "Alumaseal" type product (actually had a "Gunk" label on the little yellow-colored tube). After ten minutes of idling the leak began to subside and eventually stopped completely.

8) Thermostat housing leaked a nickel sized amount of coolant onto the intake manifold which I dried off three times. I did not re-tighten the two bolts. Leak seems to have stopped on its own or with the aid of the before-mentioned Alumaseal. I re-tightened the radiator hose clamps for good measure while I was thinking about it.

9) a. Both automatic transmission lines leaked at the radiator cooler. I re-tightened them and seems to be OK now.

b. One of the A/T cooler lines was cut by previous owner and patched with rubber line (about a 3 inch section) and hose clamps. One end of the patch (I used new rubber line) was dripping a little. I tightened the clamp three times so far, I think this last time I finally stopped the leak.

c. Another one of the A/T cooler lines was cut by previous owner and patched with a compression fitting which was dripping slightly. I retightened the fitting which seems to have stopped the drip.

10) The little access cover at the bottom of the bell-housing where one can access the four torque convertor bolts has not been replaced yet. The area inside that spot is slightly damp with ATF fluid but not enough yet to start dripping on the ground. Don't know what's going on inside there.

11) Vehicle would not move in forward or reverse. Torqueflite dipstick showed over-filled while stopped and while running. After the cable adjustment and moving the gear select back in forth, the rear wheel(s) would spin in both reverse and drive. Now dipstick shows one or more pints ATF low. Vehicle still up on jack stands so roadworthiness of rebuilt Torqueflite still in question.

12) While purging air from power steering pump for the first time with the wheels off the ground, I found a small puddle of fluid on the floor. I could find no leaks in neither the pressure line or return line. It appears the fluid overflowed out from under the reservoir cap (not 100% sure).

P.S. Problem updates: 1) Oil pan drain plug still drippy after tightening it once. Used a torque wrench a second time to 20 ft.lbs which gave the plug another 1/4 turn and now it stays dry. 2) & 10) The torqueflite has minor drips from both the end of the tailshaft and from below the torque convertor. 7) The leak from the water pump bolt previously "cured" by Alumaseal began once again. The remedy was to replace the corroded aluminum timing chain cover that was not able to crush the water pump gasket in the area of the leaky bolt hole. While the front of the motor was apart, I also drilled a camshaft thrust plate bolt in order to oil the timing chain (it looked to be on the dry side). 8) I found one more drop of coolant on the intake manifold below the thermostat housing. Since it seems to evaporate with engine heat, I left it alone for now. 11) Once the rear wheels back were back on the ground, the Torqueflite was acting up by intermittently refusing to release the park sprawl when shifted from "park" to either "R" "N" or "D". I drove the vehicle around the block for the first time and felt the first-to-second gear shift, but unsure if drive was attained (did not drive very fast). To avoid the sticky "Park" selector problem, I used "N" and the emergency brake in place of shifting into "P".

Update: Engine up and running. Now for some good news, the factory 273 Formula S Carter AFB was able to fire up the current 318 without having been rebuilt (again). Choke is wired open (don't have the choke thermostat). Only head pipes installed for now (no x-pipe, mufflers, nor tail pipes). Cold oil pressure is 60-65 PSI (mechanical gauge). With 180 degree thermostat, coolant warms up to 210 while idling at standstill (mechanical gauge). The one-wire alternator is charging 14-plus volts with the old factory style voltage regulator (alternator amp capacity unknown). The single-point distributor provides 10 degrees advance at idle speed. Pumping the accelerator pedal two or three times provides an immediate start-up.

Problems found prior to and after initial fire-up to the previously rebuilt 318 that has been in "storage" for the past three years during the restoration process:

1) Oil pan drain plug dripped slightly after filling the crankcase with oil (Castrol 20W-50). Re-tightened plug. Note: The oil pan was replaced prior to engine installation because the later version 318 oil pan that had been used previously was interfering with the steering link.

2) When I filled the now rebuilt torque flight with fluid for the first time, ATF began to drip (but very slowly) from the very end of the tail shaft where the ball & trunnion driveshaft bolts up. I purchased a new seal (not installed yet).

3) The starter could only be activated with a remote switch connected to the solenoid. The ignition key would not function. No power found under dash past the ammeter. Bypassed the ammeter by securing both ammeter wires together and everything began to work again.

4) Engine could only be started in "park" and not in "neutral". I had to adjust the floor shift selector cable quite a bit to find the correct adjustment.

5) Engine would only run by priming carb. Needed to replace the used mechanical fuel pump (that I had cleaned and painted up nicely).

6) The large 1 3/16th bolt that secures the 90 degree oil filter adaptor was dripping engine oil. Tightening the bolt once with a correct size combination wrench I purchased (cost about twenty bucks) did not stop the drip. Removed the TTI 2 1/2 inch head pipe from that side (for access) and replaced all three gaskets that pertain to the filter adaptor. Oil Leak appears to have stopped.

7) Water pump bolt that also secures the alternator adjusting bracket leaked coolant. Replacing bolt (longer/more threads) with sealant did not solve the leak. Resorted to good old "Alumaseal" type product (actually had a "Gunk" label on the little yellow-colored tube). After ten minutes of idling the leak began to subside and eventually stopped completely.

8) Thermostat housing leaked a nickel sized amount of coolant onto the intake manifold which I dried off three times. I did not re-tighten the two bolts. Leak seems to have stopped on its own or with the aid of the before-mentioned Alumaseal. I re-tightened the radiator hose clamps for good measure while I was thinking about it.

9) a. Both automatic transmission lines leaked at the radiator cooler. I re-tightened them and seems to be OK now.

b. One of the A/T cooler lines was cut by previous owner and patched with rubber line (about a 3 inch section) and hose clamps. One end of the patch (I used new rubber line) was dripping a little. I tightened the clamp three times so far, I think this last time I finally stopped the leak.

c. Another one of the A/T cooler lines was cut by previous owner and patched with a compression fitting which was dripping slightly. I retightened the fitting which seems to have stopped the drip.

10) The little access cover at the bottom of the bell-housing where one can access the four torque convertor bolts has not been replaced yet. The area inside that spot is slightly damp with ATF fluid but not enough yet to start dripping on the ground. Don't know what's going on inside there.

11) Vehicle would not move in forward or reverse. Torqueflite dipstick showed over-filled while stopped and while running. After the cable adjustment and moving the gear select back in forth, the rear wheel(s) would spin in both reverse and drive. Now dipstick shows one or more pints ATF low. Vehicle still up on jack stands so roadworthiness of rebuilt Torqueflite still in question.

12) While purging air from power steering pump for the first time with the wheels off the ground, I found a small puddle of fluid on the floor. I could find no leaks in neither the pressure line or return line. It appears the fluid overflowed out from under the reservoir cap (not 100% sure).

P.S. Problem updates: 1) Oil pan drain plug still drippy after tightening it once. Used a torque wrench a second time to 20 ft.lbs which gave the plug another 1/4 turn and now it stays dry. 2) & 10) The torqueflite has minor drips from both the end of the tailshaft and from below the torque convertor. 7) The leak from the water pump bolt previously "cured" by Alumaseal began once again. The remedy was to replace the corroded aluminum timing chain cover that was not able to crush the water pump gasket in the area of the leaky bolt hole. While the front of the motor was apart, I also drilled a camshaft thrust plate bolt in order to oil the timing chain (it looked to be on the dry side). 8) I found one more drop of coolant on the intake manifold below the thermostat housing. Since it seems to evaporate with engine heat, I left it alone for now. 11) Once the rear wheels back were back on the ground, the Torqueflite was acting up by intermittently refusing to release the park sprawl when shifted from "park" to either "R" "N" or "D". I drove the vehicle around the block for the first time and felt the first-to-second gear shift, but unsure if drive was attained (did not drive very fast). To avoid the sticky "Park" selector problem, I used "N" and the emergency brake in place of shifting into "P".