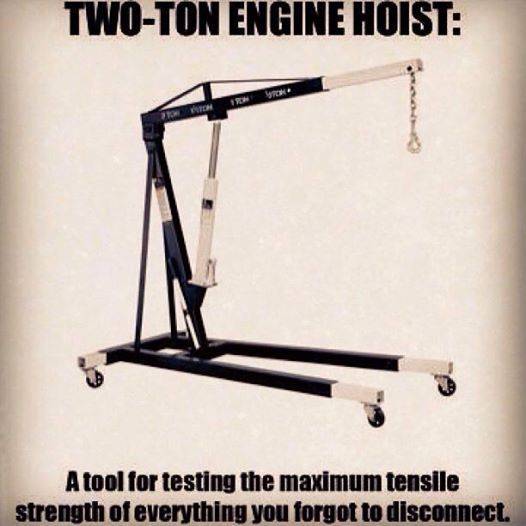

Safety Reminder!

On to the engine hoist. I knew the bolts holding it together were loose, because I could feel the hoist sway with weight on it independent of the legs. Time to tighten things up. So we took the lift arm off and flipped it on its side. I removed all four adjuster bolts from the legs, cleaned them up good, put some high temp ceramic brake grease on them and reinstalled them. Same with the lift arm adjusting bolt. All of the structural bolts, I removed, cleaned and put blue locktite on and re-torqued. I also got my grease needle and greased all of the casters good. They really need replacing, but that'll have to wait until the budget is in better shape. I plan on replacing the casters and also get an air over hydraulic ram for it, to make using it even easier.

This is no weenie hoist. It's not the foldable type. It's the old HEAVY duty one. My friend, Robbie Armstrong (RIP) who died earlier this year gave it to me several years ago as he said it was "something he'd never use" and knew that I would. ......and I have used it a good bit. Now, it's solid as a ROCK and very stead and rolls much better, even though it does need new casters. I know Robbie would be glad I have "reconditioned" it and that I use it so much. It's been a big help. So remember, to check the fasteners on your shop equipment! Here's the beast.

View attachment 1715796339