Timing by Vacuum Reading?

Here is our detailed installation guide that is on our website, and was just updated. section 6 is how we recommend setting timing.

https://cdn.shopify.com/s/files/1/2...llation_Guide_-_Single_Pages.pdf?v=1631108823

IF the engine was purchased as a complete dressed unit, with distributor, we set the timing at the plant, and Chisel mark the distributor/intake so timing can be set, in case it get bumped, within at least a few degrees. i see this is an MSD, and 6AL, which didn't come from us.

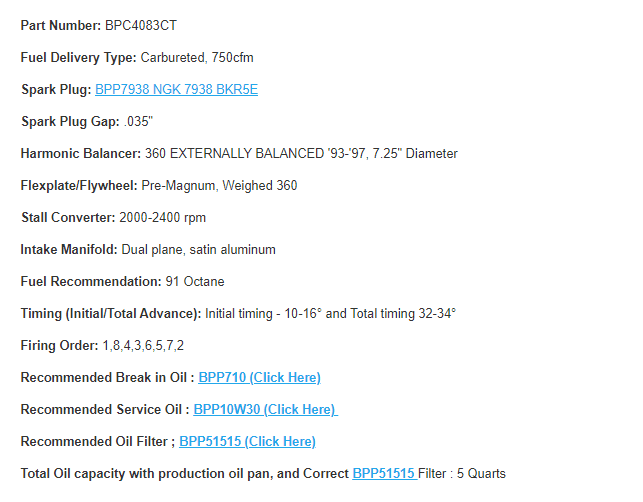

Total and initial timing requirements are on the recommendations page online. 34 total is all these need. NOT any more.

Mopar 408CI Stroker Crate Engine | Small Block Chrysler | Fully Dressed | Roller Cam

This should be as simple as verifying total timing at XXXX RPM (wherever it stops advancing). Then idling it down, and verifying initial timing is within 10-16. If it's not, then those pro billets have limiter bushing options to limit total travel. if you want to play with the curve, they also obviously have different strength springs.

NOW, all that being said... i don't see it mentioned if the "roughness" cleans up at any point, or gets worst given different driving conditions. We're alot of information away from just assuming the distributor has the wrong advance springs, but i'm also assuming bob has checked the timing as described in our guide, and it's been verified with a timing light to be correct.

I don't recall if this left with an/or intake and carb on it. But "roughness" could be anything from a blown power valve, to something as minor as jetting or idle mixture adjustments, choke operation, fuel pressure, something disrupting airflow, etc.

I'm not on here all the time, so please feel free to reach out to tech at 308-236-1050. ask for ken or brian, they are the senior guys.

Here is our detailed installation guide that is on our website, and was just updated. section 6 is how we recommend setting timing.

https://cdn.shopify.com/s/files/1/2...llation_Guide_-_Single_Pages.pdf?v=1631108823

IF the engine was purchased as a complete dressed unit, with distributor, we set the timing at the plant, and Chisel mark the distributor/intake so timing can be set, in case it get bumped, within at least a few degrees. i see this is an MSD, and 6AL, which didn't come from us.

Total and initial timing requirements are on the recommendations page online. 34 total is all these need. NOT any more.

Mopar 408CI Stroker Crate Engine | Small Block Chrysler | Fully Dressed | Roller Cam

This should be as simple as verifying total timing at XXXX RPM (wherever it stops advancing). Then idling it down, and verifying initial timing is within 10-16. If it's not, then those pro billets have limiter bushing options to limit total travel. if you want to play with the curve, they also obviously have different strength springs.

NOW, all that being said... i don't see it mentioned if the "roughness" cleans up at any point, or gets worst given different driving conditions. We're alot of information away from just assuming the distributor has the wrong advance springs, but i'm also assuming bob has checked the timing as described in our guide, and it's been verified with a timing light to be correct.

I don't recall if this left with an/or intake and carb on it. But "roughness" could be anything from a blown power valve, to something as minor as jetting or idle mixture adjustments, choke operation, fuel pressure, something disrupting airflow, etc.

I'm not on here all the time, so please feel free to reach out to tech at 308-236-1050. ask for ken or brian, they are the senior guys.