Small block TrickFlow heads part 1

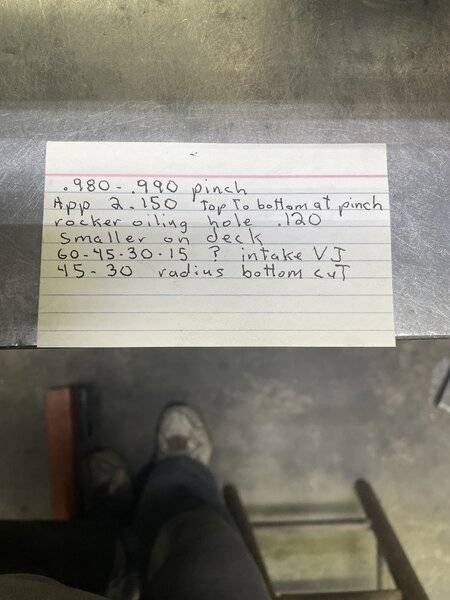

Ok the intake valve job appears to be at least 4 angles which I would guess to be a nice deep 60-45-30- and a 15 or 10. I’ve found 6-8 cfm on that top cut on sucky Edelbrock chambers. The spark plug hole has been relieved. It’s still buried but laid back nicely like we did on the Speedmaster and Edelbrock heads. The chamber’s need a little work around the valves but this is common on cnc’d heads. The deck looks rougher than it feels and would be fine with Cometic Gaskets. Now for an issue that jumped out that needs addressed. The rocker oiling hole is much smaller. It measures .120 under the shaft BUT they drill the oiling hole then surfaced the heads closing the hole a lot on the deck surface. Check your heads guys as it’s a 30 second fix. Ok that’s all I can think of right now but I know I will be adding something. Wedding reception tomorrow and church Sunday and I also have a black duster to finish but I will try to post up beginning flow numbers so I can start port work as I get a chance.

Ok the intake valve job appears to be at least 4 angles which I would guess to be a nice deep 60-45-30- and a 15 or 10. I’ve found 6-8 cfm on that top cut on sucky Edelbrock chambers. The spark plug hole has been relieved. It’s still buried but laid back nicely like we did on the Speedmaster and Edelbrock heads. The chamber’s need a little work around the valves but this is common on cnc’d heads. The deck looks rougher than it feels and would be fine with Cometic Gaskets. Now for an issue that jumped out that needs addressed. The rocker oiling hole is much smaller. It measures .120 under the shaft BUT they drill the oiling hole then surfaced the heads closing the hole a lot on the deck surface. Check your heads guys as it’s a 30 second fix. Ok that’s all I can think of right now but I know I will be adding something. Wedding reception tomorrow and church Sunday and I also have a black duster to finish but I will try to post up beginning flow numbers so I can start port work as I get a chance.