I considered making one but honestly I only use one to give others info. That number honestly does nothing for me.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small block TrickFlow heads part 1

- Thread starter pittsburghracer

- Start date

-

Something I forgot to show you guys

An early assembly he just got?

It’s funny how “we” forget if they just reading it! LMAO!

MOPAROFFICIAL

Oogliboogli

Take and cut one pipe from a trashed hedman or hooker header at the flange. Cheap and easy.I considered making one but honestly I only use one to give others info. That number honestly does nothing for me.

Take and cut one pipe from a trashed hedman or hooker header at the flange. Cheap and easy.

Like I said that number means nothing to me. It would be different if I was trying to drum up work or impress someone but I’m not so I don’t. If it’s quiet and 325fps speed I’m happy and know it will work. Any cfm gained is a bonus doing what I have to do to hit my goal. After three days I finally got a return phone call from the guys at TrickFlow. They answered a few questions I had and I asked them if the small block Mopar race head was still going forward and he said they were on hold on a lot of developmental work right now. Honestly I don’t blame them because if you can’t keep the products you are presently making in stock why go forward on new products. He wasn’t sure if they were having guys at Norwalk next week or not but he said they cut back on a lot of shows for now.

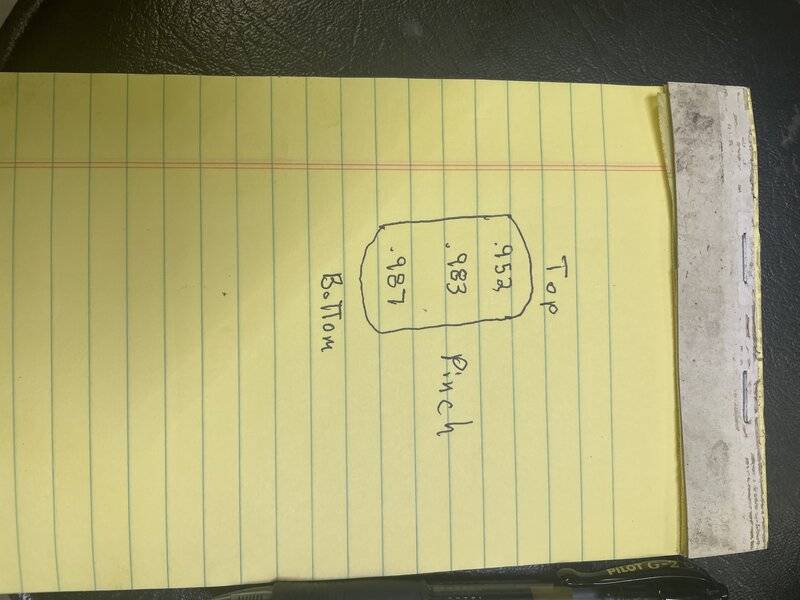

Ok here’s a little picture of the pinch measurements and as you can see it’s tapered. As I open it I’m technically moving the pinch towards the valve. Two things are going on. The common wall is tapered in as it goes towards the valve and the pinch wall tilts in. So as I open the pinch I’m also working it towards the valve. I’m going slow and easy because a fix would require me to break out the welder (I already fixed an intake today) I’ll remove.015-.020 and sonic check it. Even doing that it’s tricky. I’m not touching the common wall till after I flow it so I can give you guys an accurate figure. Snap gauges are your friend here and a cheap investment. Ohhh I’m up to 1.050 now and you should be able to see the difference. I’ll sonic check it after a small break and see if I can gain anymore. I would like to leave at least .050 of material.

MOPAROFFICIAL

Oogliboogli

Will it speed that wall now.

Will it speed that wall now.

Yes but I’m going to recommend backing off on making the pinch that big. When I’m grinding an unknown thickness area like that I go real slow with my burr. I can actually hear changes in sound and I think I’m getting thin, to thin. I have the exhaust to do and a job on my black duster. If I get a chance I’m going to probe around with a pick. If it’s thin I’ll run a bead of weld on it. I’m trying to find a safe number for you guys before I touch the common wall. For sure I will be hitting the roof some too as it runs downhill to the pinch. I want to be able to flow both the intake and exhaust at the same time and hopefully I will only have to flow the exhaust once.

cookietruck

Well-Known Member

Got some Indy X-heads from my brother so, I was looking up IMM builds and flow numbers for the Indy X-heads he was prepping and came across the IMM instagram account.

Pretty sure I saw some small block LA Trick Flow heads he did some porting on. maybe @ou812 could chime in a bit here.

EDIT: oh nvm, i see he is already in this thread..

Pretty sure I saw some small block LA Trick Flow heads he did some porting on. maybe @ou812 could chime in a bit here.

EDIT: oh nvm, i see he is already in this thread..

Ironracer

Gearhead

Damn... Amazing talent there!

Ok guys finally spent a little more time on this head tonight’s. I’m going to say I spent 10 minutes on the exhaust port. I held a stock Mr Gasket header gasket on the head and the lower part of the gasket cam to that line you can see on the exhaust port. I took about 1/2 that distance and you can see in the side by side. I removed the cnc cutter marks smoothing the port with a carbide burr. I knocked that lip off the valve seat and slightly shaped the short side widening it some. Airflow at .500 with a tube ( 2 inch) went from 221 to 239. At .550 went from 261 to 248cfm with the tube.

Exhaust flow numbers

————stock————ported

.100—-43—————-43

.200—105—————106

.300—154—————158

.400—181—————193

.500—191—————207

.600—195—————213

.700—198—————217

Port airspeed is quiet, calm, and much faster. .500 lift speed went from 255fps to 330fps.

————stock————ported

.100—-43—————-43

.200—105—————106

.300—154—————158

.400—181—————193

.500—191—————207

.600—195—————213

.700—198—————217

Port airspeed is quiet, calm, and much faster. .500 lift speed went from 255fps to 330fps.

Intake flow numbers. Now remember I worked the pushrod part of the pinch and never touched the common wall, roof, or floor. (I will be) speed at the pinch was slower but as I knew it would be still high. I will try to give better details on that tomorrow. Ohhh I did remove that slight ridge I talked about earlier in this post. Cnc always leaves a slight lip.

intake flow numbers

————stock (my bench). Pinch work

.100———-67—————74

.200———132————-133

.300———195————-199

.400———245————-248

.500———280————-283

.600———298————-298

.700———300————-307

.800———300————-309

at .850 lift this port finally went turbulent BUT and this is odd when I backed it off to .800 lift again it immediately calmed down. I find you usually have to drop the depression to calm it. As you can see these were small gains but now we go for it. I forgot to add the exhaust port pictures to see the small mods on the exit so I will add them here this will be dressed up more before it’s done

intake flow numbers

————stock (my bench). Pinch work

.100———-67—————74

.200———132————-133

.300———195————-199

.400———245————-248

.500———280————-283

.600———298————-298

.700———300————-307

.800———300————-309

at .850 lift this port finally went turbulent BUT and this is odd when I backed it off to .800 lift again it immediately calmed down. I find you usually have to drop the depression to calm it. As you can see these were small gains but now we go for it. I forgot to add the exhaust port pictures to see the small mods on the exit so I will add them here this will be dressed up more before it’s done

Hi from Australia, i have a 3388lb VG Valiant Hardtop(68 Dart), 408 cubes flat tops, trickflow 190 óut of box, supervictor, 840cfm prosystems E85, 254/260 hyd roller .627 lift,108lsa, 1.65 rockers, 1 3/4 tri y pipes, 727 9 1/2 convertor, 8.75 rear 3.91 gears 28 tire.

et 10.53 126.98mph.

ATTACH=full]1715805358[/ATTACH]

et 10.53 126.98mph.

ATTACH=full]1715805358[/ATTACH]

Last edited:

stixx

Well-Known Member

That should be considered fast enough for OOTB trickflows...

360duster

Well-Known Member

yes, pretty fast (and quick) ;-)

what´s the Cams LSA?

Michael

what´s the Cams LSA?

Michael

360duster

Well-Known Member

oh, sorry John.....don´t want to derail your thread of course.....keep going!

ChargedDart75

Well-Known Member

That's great work man! This has definitely been a better read than your Walmart threads.

Very very nice. This should be reposted in the racers forum up top where the stickies are with a little more detail to help everyone with there search on “How to” get it done. Welcome aboard!

Hi from Australia, i have a 3388lb VG Valiant Hardtop(68 Dart), 408 cubes flat tops, trickflow 190 óut of box, supervictor, 840cfm prosystems E85, 254/260 hyd roller .627 lift 1.65 rockers, 1 3/4 tri y pipes, 727 9 1/2 convertor, 8.75 rear 3.91 gears 28 tire.

et 10.53 126.98mph.

ATTACH=full]1715805358[/ATTACH]

View attachment 1715805359

Thank you Sir for you information.Hi from Australia, i have a 3388lb VG Valiant Hardtop(68 Dart), 408 cubes flat tops, trickflow 190 óut of box, supervictor, 840cfm prosystems E85, 254/260 hyd roller .627 lift 1.65 rockers, 1 3/4 tri y pipes, 727 9 1/2 convertor, 8.75 rear 3.91 gears 28 tire.

et 10.53 126.98mph.

ATTACH=full]1715805358[/ATTACH]

View attachment 1715805359

Well Done!

oh, sorry John.....don´t want to derail your thread of course.....keep going!

I would like to read about more builds like that. For some reason some guys seem afraid to start their own post and share their build with us. We haven’t heard enough good stories about these heads and have discussed many of those reasons (.525 lift cams and 3500 stall converters). I would love to see a post about his build with lots of pictures of his car. I know you guys would too.

You don’t see them because, IMO it’s the arm chair quarterbacks. The “I would have” “You should have” and my favorite, “That cam sucks, you fucked up, I bet that’s a slug out of the hole until *** rpm.”

Oh! And coupled with the “Mathematician” know it all’s that insult in a way without being direct. The other half of the bunch don’t even realize what they’re saying and they’re telling you how stupid you are. That also applies for every other part of the engine & car build.

No one really wants to hear someone else’s opinion and **** when it’s not asked for.

Oh! And coupled with the “Mathematician” know it all’s that insult in a way without being direct. The other half of the bunch don’t even realize what they’re saying and they’re telling you how stupid you are. That also applies for every other part of the engine & car build.

No one really wants to hear someone else’s opinion and **** when it’s not asked for.

You don’t see them because, IMO it’s the arm chair quarterbacks. The “I would have” “You should have” and my favorite, “That cam sucks, you fucked up, I bet that’s a slug out of the hole until *** rpm.”

Oh! And coupled with the “Mathematician” know it all’s that insult in a way without being direct. The other half of the bunch don’t even realize what they’re saying and they’re telling you how stupid you are. That also applies for every other part of the engine & car build.

No one really wants to hear someone else’s opinion and **** when it’s not asked for.

I hear you but you can’t be a cupcake about it either. There is a lot of knowledge on this site with most willing to share info. If someone tells you you won’t see a difference in performance if you trade off your ported Edelbrock heads for a set of TrickFlow heads and you are running a 550 lift cam don’t get upset. I have a fault with my communication skills as I can be abrasive. Arrogance and my work environment for 33 years in the mill made you learn to defend your ground.

-