mopowers

Well-Known Member

I realize a lot of the previous photos got wrapped up in the whole photobucket fiasco, but I’ve finally got some updates now that I’m able to devote some time to this project. I apologize for all of the photos.

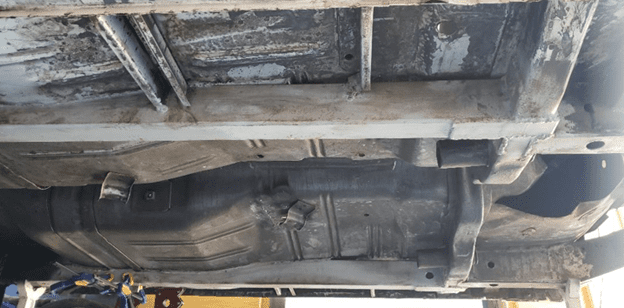

Anyhow - I spent quite a bit of time scraping undercoating and wiping the residue off with goof off and brake cleaner. When all was said and done, there was about 25 lbs of undercoating scraped off. That’s one job I hope to never do again! Bottom photo is just a random shot of the two turds at this stage.

I've been keeping sort of a journal of the build, so bear with me while I load the photos.

Anyhow - I spent quite a bit of time scraping undercoating and wiping the residue off with goof off and brake cleaner. When all was said and done, there was about 25 lbs of undercoating scraped off. That’s one job I hope to never do again! Bottom photo is just a random shot of the two turds at this stage.

I've been keeping sort of a journal of the build, so bear with me while I load the photos.