Header Fabrication

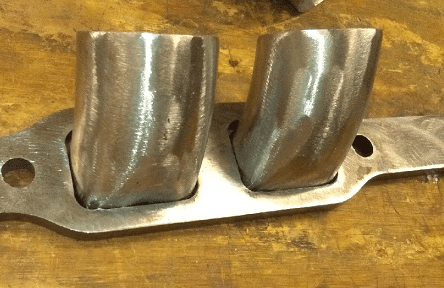

These are great tips! Your headers look awesome!!! For these logs, I just ended up using my bench vise to squeeze the tube one way, and a big pair of vise grip clamps to square it up the other way. Then a big punch and hammer to make adjustments. It turned out working pretty well.

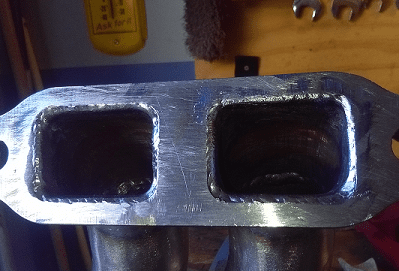

Since I wasn't sure whether to weld the inside or the outside, I did both just to be safe., then ran a flat file over it to ensure the flange was perfectly flat. I just wish I had a good friend who was a good tig welder. Hopefully everything seals.

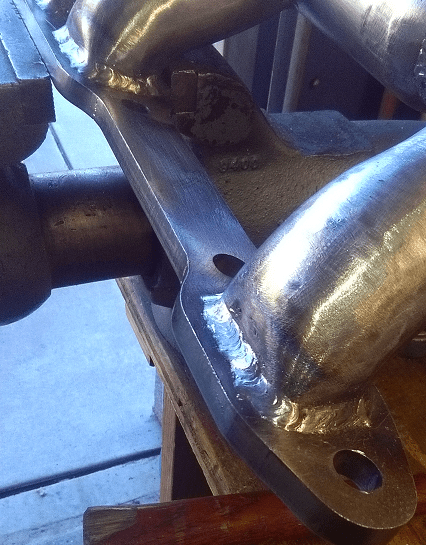

Lastly - don't ever buy j-bends from Hooker. I couldn't believe how rusty these were on the inside.

These are great tips! Your headers look awesome!!! For these logs, I just ended up using my bench vise to squeeze the tube one way, and a big pair of vise grip clamps to square it up the other way. Then a big punch and hammer to make adjustments. It turned out working pretty well.

Since I wasn't sure whether to weld the inside or the outside, I did both just to be safe., then ran a flat file over it to ensure the flange was perfectly flat. I just wish I had a good friend who was a good tig welder. Hopefully everything seals.

Lastly - don't ever buy j-bends from Hooker. I couldn't believe how rusty these were on the inside.