pishta

I know I'm right....

I told him to check the flange orientation back in post #2. all 273 early A manifolds point back...

67s started to point down

340's point slightly forward and have larger ports.

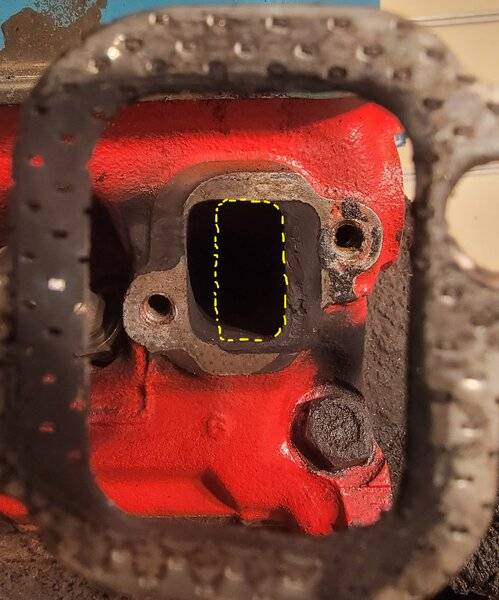

You may end up getting away with just a clean up and a proper gasket orientation. It looks like you got plenty of surface there. Your post 9 pic and my post 4 pic look about the same. By opening up your port, your going to exceed the gasket profile and that will not help. Just try the (new) gasket the correct position and it should seal right up.

67s started to point down

340's point slightly forward and have larger ports.

You may end up getting away with just a clean up and a proper gasket orientation. It looks like you got plenty of surface there. Your post 9 pic and my post 4 pic look about the same. By opening up your port, your going to exceed the gasket profile and that will not help. Just try the (new) gasket the correct position and it should seal right up.