craftsman drill press run out

Check a piece of rod in the chuck.

Mount a piece of bar stock to the table and have it just touch the rod.

Rotate the chuck till you find the high spot on the rod, then rotate it till you find the liw spot and use a feeler guage to determin the amount of runout.

Not as accurite as a gauge but should get you a feel for things.

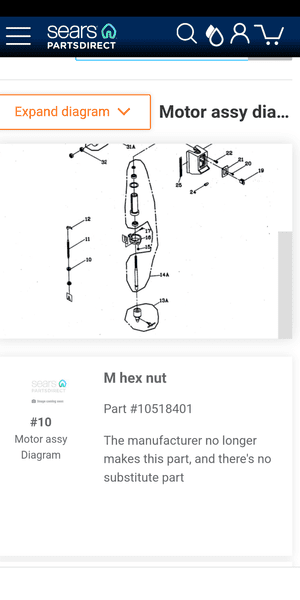

Looks like the spindle is in a sleave type bearing (not roler bearings etc)

Looks like you could remove the spindle fairly easily. If you do have excess runout, it could be the sleave, or the spindle, or the spindle is bent.

Check a piece of rod in the chuck.

Mount a piece of bar stock to the table and have it just touch the rod.

Rotate the chuck till you find the high spot on the rod, then rotate it till you find the liw spot and use a feeler guage to determin the amount of runout.

Not as accurite as a gauge but should get you a feel for things.

Looks like the spindle is in a sleave type bearing (not roler bearings etc)

Looks like you could remove the spindle fairly easily. If you do have excess runout, it could be the sleave, or the spindle, or the spindle is bent.