There was a comment in another thread that they are farming out cams, I hate hearing that, & worse I was planning on getting another custom grind for this Olds 455 from them. The previous one has been in & running for almost 14yrs now w/o a single issue, broken in on the outers, wanted to add a bit more dur & tighten the lobe centers up the same, now I'm debating to leave it or find another grinder....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Comp cam warranty

- Thread starter plymouth1937

- Start date

-

Most likely the lifters, not the cam. Lifters made out of crap-anium.

Keep saying it on this forum & others: if you don't want your FT lifters to fail, find some used stock lifters [ or 25+ yr aftermarket lifters ] & have them re-faced.

Keep saying it on this forum & others: if you don't want your FT lifters to fail, find some used stock lifters [ or 25+ yr aftermarket lifters ] & have them re-faced.

plymouth1937

Well-Known Member

Ok took a another look at the dicaster today and i agree whid you this lifters are not up for the task considering what lean springs i run and absolutly no binding im gona post a picture later today then you all can take a look the lifter looks like a sop bole whid a hole in the middleMost likely the lifters, not the cam. Lifters made out of crap-anium.

Keep saying it on this forum & others: if you don't want your FT lifters to fail, find some used stock lifters [ or 25+ yr aftermarket lifters ] & have them re-faced.

plymouth1937

Well-Known Member

Here it is

plymouth1937

Well-Known Member

Thay look ok just one broken lifter gona jank the cam tomorow and messure the lobe if its ok or not probably not okWhat do the rest look like?

Unfortunately I'd say chances are between 100 & 100% it's toast..Thay look ok just one broken lifter gona jank the cam tomorow and messure the lobe if its ok or not probably not ok

plymouth1937

Well-Known Member

YuppUnfortunately I'd say chances are between 100 & 100% it's toast..

plymouth1937

Well-Known Member

Yupp looking at a total rebuild anybody have any sugestions on cam choise if i dont get a new cam and lifters on warranty i Will not buy any cam related stuff from comp cams from here on looking for a cam like the 268hNot to mention the metal flakes down in the pan and/or maybe oil filter......

plymouth1937

Well-Known Member

Ok thanks il look in on thatI've always had good luck with Isky cams in the past, but, I haven't had to buy one lately, so, I can't speak for their current stuff. Mine have all been solid cams though.

PRH

Well-Known Member

I’m shocked at how thin the bottom of that lifter is.

That’s not worn nearly enough to end up with a hole in the bottom imo.

Be interesting to compare the thickness of an old OE lifter vs what you can buy now.

Edit......

I have some Crane BB hyd lifters from about 30 years ago here, and some solids that might be a few years newer.

I took them apart, and there is a small counterbore at the bottom of each.

The area at the bottom of that counterbore is only about .125” thick on the hyd lifter, and maybe .015” or so thicker on the solid.

That’s only for a small circular area right in the center....... where the hole is in the OP’s pic.

The area outside of the counterbore is about .040-.050” thicker.

I don’t have any “new” lifters here to compare.

That’s not worn nearly enough to end up with a hole in the bottom imo.

Be interesting to compare the thickness of an old OE lifter vs what you can buy now.

Edit......

I have some Crane BB hyd lifters from about 30 years ago here, and some solids that might be a few years newer.

I took them apart, and there is a small counterbore at the bottom of each.

The area at the bottom of that counterbore is only about .125” thick on the hyd lifter, and maybe .015” or so thicker on the solid.

That’s only for a small circular area right in the center....... where the hole is in the OP’s pic.

The area outside of the counterbore is about .040-.050” thicker.

I don’t have any “new” lifters here to compare.

Last edited:

PRH

Well-Known Member

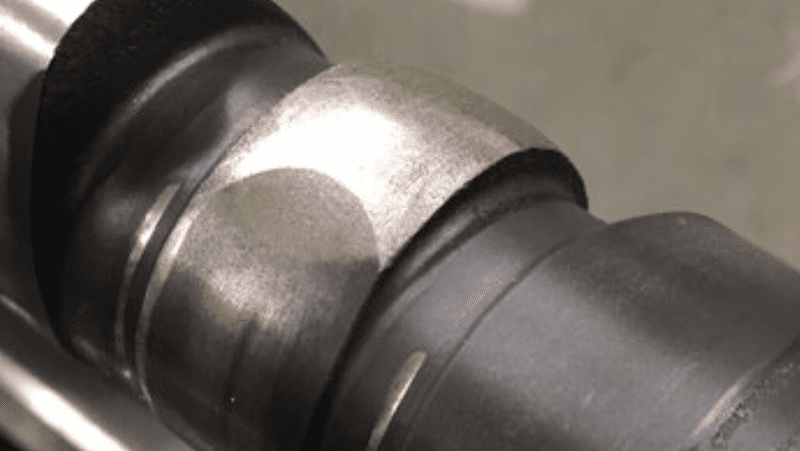

Here is one from a couple of years ago.

Aggressive solid and the springs were set up wrong, along with being run with oil that wasn’t high zinc.

I measured a couple of the other lifters that were companions to this one, it was also .135” thick in the center of the counterbore.

The wear on this one measures .100” deep.

Matching lobe:

It was discovered after the end of the season.

Cam was replaced with something a little smoother, spring set-up issue was corrected, strict diet of high zinc oil....... no problems in a couple seasons of use.

Aggressive solid and the springs were set up wrong, along with being run with oil that wasn’t high zinc.

I measured a couple of the other lifters that were companions to this one, it was also .135” thick in the center of the counterbore.

The wear on this one measures .100” deep.

Matching lobe:

It was discovered after the end of the season.

Cam was replaced with something a little smoother, spring set-up issue was corrected, strict diet of high zinc oil....... no problems in a couple seasons of use.

Last edited:

aaronk785

Well-Known Member

I’ve lost 2 cams in my life. Both where comp cam and lifters. Just saying. If the engine is going to set for a time before initial start up. Don’t use the supplied cam lube. Use a moly paste. Like isky rev lube or similar.

PRH

Well-Known Member

One of my regular customers, who uses quite a few SFT cams was checking for lifter rotation on a 505 he’s putting together.

One lifter wasn’t turning at all.

Swapped lifters with one that was turning, no difference.

So...... it’s either the cam or the block.

Pulled the cam out, measured the lobe taper...... same as the others.

The choices at that point are....... bush the block, or roller cam.

Had it not been checked for lifter rotation...... it would have failed.

I usually check for lifter rotation very early in the cam installation process........ but I check the lobe taper before even sliding the cam into the block.

One lifter wasn’t turning at all.

Swapped lifters with one that was turning, no difference.

So...... it’s either the cam or the block.

Pulled the cam out, measured the lobe taper...... same as the others.

The choices at that point are....... bush the block, or roller cam.

Had it not been checked for lifter rotation...... it would have failed.

I usually check for lifter rotation very early in the cam installation process........ but I check the lobe taper before even sliding the cam into the block.

Bobzilla

Well-Known Member

I wonder if that was an EDM lifter, so the hole is not really telling us the thickness of the face on that luifter.I’m shocked at how thin the bottom of that lifter is.

That’s not worn nearly enough to end up with a hole in the bottom imo.

Be interesting to compare the thickness of an old OE lifter vs what you can buy now.

Edit......

I have some Crane BB hyd lifters from about 30 years ago here, and some solids that might be a few years newer.

I took them apart, and there is a small counterbore at the bottom of each.

The area at the bottom of that counterbore is only about .125” thick on the hyd lifter, and maybe .015” or so thicker on the solid.

That’s only for a small circular area right in the center....... where the hole is in the OP’s pic.

The area outside of the counterbore is about .040-.050” thicker.

I don’t have any “new” lifters here to compare.

Bobzilla

Well-Known Member

One of my regular customers, who uses quite a few SFT cams was checking for lifter rotation on a 505 he’s putting together.

One lifter wasn’t turning at all.

Swapped lifters with one that was turning, no difference.

So...... it’s either the cam or the block.

Pulled the cam out, measured the lobe taper...... same as the others.

The choices at that point are....... bush the block, or roller cam.

Had it not been checked for lifter rotation...... it would have failed.

I usually check for lifter rotation very early in the cam installation process........ but I check the lobe taper before even sliding the cam into the block.

Lifter not turning is my guess as well.

In the post I linked early, there was an inspection that found the camshaft "grind" was not as wide as the casting, which caused basically a sharp edge that could easily "eat" a lifter if not addressed. I never thought of checking that in the past, but I definitely will check it on my next flat tappet camshaft. I definitely learned something reading that one.

PRH

Well-Known Member

The worn lifter I posted the pic of is an EDM lifter.

They’re still the same normal thickness as the non-EDM pieces.

.135” in the very center in those examples.

Also, there aren’t EDM hyd lifters.

It’s hard to pump up a lifter with a hole in the bottom of the pressure chamber.

I’d be very curious about just how thick the bottoms of his lifters are.

Although it’s probably a moot point.

That lobe and lifter were toast long before the hole appeared.

They’re still the same normal thickness as the non-EDM pieces.

.135” in the very center in those examples.

Also, there aren’t EDM hyd lifters.

It’s hard to pump up a lifter with a hole in the bottom of the pressure chamber.

I’d be very curious about just how thick the bottoms of his lifters are.

Although it’s probably a moot point.

That lobe and lifter were toast long before the hole appeared.

Bobzilla

Well-Known Member

Oh yeah, 268H. The H is for hydraulic isn't it. Good call PRH.The worn lifter I posted the pic of is an EDM lifter.

They’re still the same normal thickness as the non-EDM pieces.

.135” in the very center in those examples.

Also, there aren’t EDM hyd lifters.

It’s hard to pump up a lifter with a hole in the bottom of the pressure chamber.

I’d be very curious about just how thick the bottoms of his lifters are.

Although it’s probably a moot point.

That lobe and lifter were toast long before the hole appeared.

cookietruck

Well-Known Member

also, notice the size of the hole in the first failed lifter posted vs the size of the hole in the lifter PRH posted. the EDM holes are tiny, you can barely see it in PRH's photo.

that huge hole in the other lifter is not an EDM hole...

that huge hole in the other lifter is not an EDM hole...

plymouth1937

Well-Known Member

Dont knowe what an edm is but i chekt that the lifters was turning when i esebled the top end talked to my supplier today and as i knowe no refund comp cams can go f....k them self il newer bay another part from them ever againalso, notice the size of the hole in the first failed lifter posted vs the size of the hole in the lifter PRH posted. the EDM holes are tiny, you can barely see it in PRH's photo.

that huge hole in the other lifter is not an EDM hole...

PRH

Well-Known Member

Here’s a good read on a cam problem......

Solid cam damage diagnosis help

And, as is often the case........ no follow up with how things turned out in the end.

Solid cam damage diagnosis help

And, as is often the case........ no follow up with how things turned out in the end.

Last edited:

-