I installed the cam myself. It's certainly possible a lobe slightly drug on a bearing surface but I can assure no pressure required or sticking. Machine shop thinks it may have been installed poorly.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Super bummed. New motor. Bad bearings?

- Thread starter Mean416

- Start date

-

This whole thing is looking to me like they assembled the engine with engine oil, (not the thick assembly lube like STP).

Then they forgot to prime the engine oil system before first firing it up.

Looks like inadequate oil supply by the looks of those bearings, especially that cam bearing.

Looks like the bearing material is just starting to transfer to the crank journals, another sign of inadequate oiling.

Crank will clean up fine and will remove any of that transfer material with a polish.

Lucky the bearings are soft and they take the first hit.

Then they forgot to prime the engine oil system before first firing it up.

Looks like inadequate oil supply by the looks of those bearings, especially that cam bearing.

Looks like the bearing material is just starting to transfer to the crank journals, another sign of inadequate oiling.

Crank will clean up fine and will remove any of that transfer material with a polish.

Lucky the bearings are soft and they take the first hit.

Last edited:

This whole thing is looking to me like they assembled the engine with engine oil, (not the thick assembly lube like STP).

Then they forgot to prime the engine oil system before first firing it up.

Looks like inadequate oil supply by the looks of those bearings, especially that cam bearing.

Looks like the bearing material is just staring to transfer to the crank journals, another sign of inadequate oiling.

Crank will clean up fine and will remove any of that transfer material with a polish.

Lucky the bearings are soft and they take the first hit.

Thanks. The engine had break in oil and was amply pre oiled. It's hard to say for sure what happened other than I think there was some level of contamination left from whatever hot tank was used. Also I suspect the oil clearances we're tight. That's TBD. Engine is in the machine shop right now. They'll clean up the crank journals as well.

The reason I ask about the crank bearings and cam bearings being assembled with engine oil only.

Is that if they had been assembled with Lucas assembly lube (like STP) it is much thicker and goes down first and then the bearings assembled.

This thicker lube gives a better oil film and allows debris to float on past the parts without imbedding in the fresh soft bearings.

Would be interesting to hear how exactly it was assembled and what lube ?

Did the machine shop install the crank and bearings, then you installed the cam yourself?

Now you have 2 different people building on the same engine, things can go wrong.

Is that if they had been assembled with Lucas assembly lube (like STP) it is much thicker and goes down first and then the bearings assembled.

This thicker lube gives a better oil film and allows debris to float on past the parts without imbedding in the fresh soft bearings.

Would be interesting to hear how exactly it was assembled and what lube ?

Did the machine shop install the crank and bearings, then you installed the cam yourself?

Now you have 2 different people building on the same engine, things can go wrong.

When things go bad with crankshaft bearings:

A bent cam would've had drag turning it, & would've whooped the bearings 360deg, not just one side....How did the cam spin by hand when it was installed? I’ve seen bent cams come straight out of the box. Usually dropped during shipping.

TT5.9mag

Two atmospheres are better than one

A bent cam would've had drag turning it, & would've whooped the bearings 360deg, not just one side....

That’s why I asked how it spun when installed. And not necessarily, usually if caught early the signs of a bent cam will show worn on half or less of the upper of one shell and the lower of another.

Krooser

Building Chinese Free Engines since 1959...

Am I seeing std. bearings on rods made for narrow bearings? Look at the bearing overhang on the rods... does not look correct.

I don't know about post #81's situation, but mine were correct. They were supplied with the recip assy by Scat.Am I seeing std. bearings on rods made for narrow bearings? Look at the bearing overhang on the rods... does not look correct.

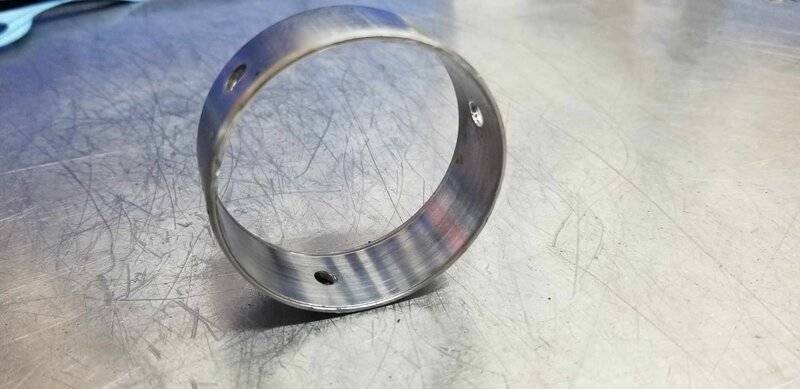

Ok so a bit of news. The #4 cam bearing was most likely clocked wrong starving that journal. So it looks like I at least found the source of the metal flakes. Plus now I know for sure I did the right thing tearing it down.

Now the plot thickens, unfortunately. The shop checked out the cylinders and they are saying they're all over the place and some out of spec. So now I gotta overbore. Super crappy but I gotta deal with it. I have a few questions for the experts here now.

1. Looking at new pistons, I'm going to go with flat tops. It'll bring me to around 11:1 compression. Question I have is, are the icon forged Pistons any good? That's what I had in the engine before but just curious how these stack up. Are there any options that are far better and why?

2. I'm seriously considering opening up the oil clearances using +.001 main bearings. Problem I'm having is I can't seem to find any. Can y'all point me in the right direction?

Now the plot thickens, unfortunately. The shop checked out the cylinders and they are saying they're all over the place and some out of spec. So now I gotta overbore. Super crappy but I gotta deal with it. I have a few questions for the experts here now.

1. Looking at new pistons, I'm going to go with flat tops. It'll bring me to around 11:1 compression. Question I have is, are the icon forged Pistons any good? That's what I had in the engine before but just curious how these stack up. Are there any options that are far better and why?

2. I'm seriously considering opening up the oil clearances using +.001 main bearings. Problem I'm having is I can't seem to find any. Can y'all point me in the right direction?

Rat Bastid

Dunamis Metron

Ok so a bit of news. The #4 cam bearing was most likely clocked wrong starving that journal. So it looks like I at least found the source of the metal flakes. Plus now I know for sure I did the right thing tearing it down.

View attachment 1715821627

Now the plot thickens, unfortunately. The shop checked out the cylinders and they are saying they're all over the place and some out of spec. So now I gotta overbore. Super crappy but I gotta deal with it. I have a few questions for the experts here now.

1. Looking at new pistons, I'm going to go with flat tops. It'll bring me to around 11:1 compression. Question I have is, are the icon forged Pistons any good? That's what I had in the engine before but just curious how these stack up. Are there any options that are far better and why?

2. I'm seriously considering opening up the oil clearances using +.001 main bearings. Problem I'm having is I can't seem to find any. Can y'all point me in the right direction?

Hone the bores back to straight and round and have the pistons coated by Line2Line coatings. That’s way cheaper than boring the cylinders and buying new pistons.

Unless you have .0015 main clearance another .001 bigger is a huge move. Too much clearance isn’t good, although the old saw that says everyone will know if it’s too tight but only you will know if it’s too loose is just that. An old myth from bygone days.

Unless there are scratches on the cyl walls, I'm having trouble with the bores being "all over the place" on a fresh engine, really? Wtf? I agree with Rat, no reason for excess brg clearances. Unless You are boosted & generating a ton of bearing load at low rpm, or extended hi rpm/load that requires extra oil flow to cool them, You're just going to throw extra oil everwhere...glad You've ID'd the culprit, & taught a valuable lesson to many, if it looks, feels, or sounds wrong.....it probably is.

Unless there are scratches on the cyl walls, I'm having trouble with the bores being "all over the place" on a fresh engine, really? Wtf? I agree with Rat, no reason for excess brg clearances. Unless You are boosted & generating a ton of bearing load at low rpm, or extended hi rpm/load that requires extra oil flow to cool them, You're just going to throw extra oil everwhere...glad You've ID'd the culprit, & taught a valuable lesson to many, if it looks, feels, or sounds wrong.....it probably is.

The machine shop measured the bores and noted some were out of spec some were in spec. A lot of variance in diameter. I think the shop I sent it to originally was not competent.

Keep thorough documentation, ask new shop to do the same, go to court. Get Your $$$$ back. I re-did a head gasket for a neighbor of My Folks long ago, had a "pro" somewhere else do it after having suffered a stroke, lasted maybe 2 mos. FWD Iron Duke in a Buick, looked like they gunned the head down from one end to the other, w/a visable diff in compression. Took the gasket with Him, walked out of the Magistrate's with His money back, incl. Court costs.The machine shop measured the bores and noted some were out of spec some were in spec. A lot of variance in diameter. I think the shop I sent it to originally was not competent.

I would take this route but it's been way too long. Close to 10 years.Keep thorough documentation, ask new shop to do the same, go to court. Get Your $$$$ back. I re-did a head gasket for a neighbor of My Folks long ago, had a "pro" somewhere else do it after having suffered a stroke, lasted maybe 2 mos. FWD Iron Duke in a Buick, looked like they gunned the head down from one end to the other, w/a visable diff in compression. Took the gasket with Him, walked out of the Magistrate's with His money back, incl. Court costs.

Rings, quick bead hone. New rods, mains, and cam bearings. Clean up your crank and cam. Same pistons, put her together and get 'er done.

Watch your pennies and the dollars will take care of themselves.

Watch your pennies and the dollars will take care of themselves.

I wish I could just do the hone job but the way I am I will always worry about poor ring seating and lost power with out of spec cylinders. I'd rather spend a few bucks and be confident it's in good shape.

On another note I have a set of icon forged Pistons for sale. 4.070 bore. 1 hour run time so basically brand new PM me if interested.

On another note I have a set of icon forged Pistons for sale. 4.070 bore. 1 hour run time so basically brand new PM me if interested.

I wish I could just do the hone job but the way I am I will always worry about poor ring seating and lost power with out of spec cylinders. I'd rather spend a few bucks and be confident it's in good shape.

On another note I have a set of icon forged Pistons for sale. 4.070 bore. 1 hour run time so basically brand new PM me if interested.

Was the block originally honed with deck plates, and if so, did the new shop measure the bores with deck plates bolted on?

Supposedly so, yes.Was the block originally honed with deck plates, and if so, did the new shop measure the bores with deck plates bolted on?

The new shop did use them.

-