Well it's shiny but is the **** runnin yet? I mean seriously. lol

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

174/177 supercharged small block, where to start?

- Thread starter mopardude318

- Start date

-

mopardude318

Well-Known Member

From your picture it looked like you had studs, I was going to ask for part number. Would be cool to find some. Thanks

Alright, more fartin around and not much progress, but I found a stud that will work for the first 3. It is this one here:

https://eastcoastspeed.com/item/5759864-716-14-stud-6950-oal-broached

I ordered 3 and got them installed used an ARP 12 point nut & washer.

Original stud on the left, Allen in the middle and the ARP on the right. Hope that helps.

And Rusty, I’ll be working on the fuel system this weekend. I got my Aeromotive in tank fuel pump I have to install and run some 1/2” feed & return lines.

DARTGAME

SuPeRcHaRgEd

Thanks man! Found them ARP AP6.950-1LGB - 7/16-14 Stud 6.950 OAL Broached-ARPAP6.95 for $8.95 each using ARP part number.

Alright, more fartin around and not much progress, but I found a stud that will work for the first 3. It is this one here:

https://eastcoastspeed.com/item/5759864-716-14-stud-6950-oal-broached

I ordered 3 and got them installed used an ARP 12 point nut & washer.

Original stud on the left, Allen in the middle and the ARP on the right. Hope that helps.

And Rusty, I’ll be working on the fuel system this weekend. I got my Aeromotive in tank fuel pump I have to install and run some 1/2” feed & return lines.

View attachment 1715822819

View attachment 1715822821

Just crank it up already. lol Seriously, lookin good, man.

DARTGAME

SuPeRcHaRgEd

James what carb you using? Is it supercharger specific? Happy thanksgiving!

mopardude318

Well-Known Member

Yes it is a Holley 750 Supercharger carb.James what carb you using? Is it supercharger specific? Happy thanksgiving!

Holley 0-80573S Holley 4150 Supercharger Carburetors | Summit Racing

DARTGAME

SuPeRcHaRgEd

Want to get a new carb, was curious what you had. I have a vac secondary with the choke horn milled off, it’s not boost referenced.

Picked up a 1190 belt today to run the smaller pulley, what a world of difference it made, however I'll need sort out the thermostat housing and rad hose better as it blew the hose off on a hard run and made one helluva mess.

mopardude318

Well-Known Member

Post pics of your setup if ya can. Odd thing about your radiator hose blowing off, what’s that about? I couldn’t find an 1190 belt so I made what I had work. What’s the PN?Picked up a 1190 belt today to run the smaller pulley, what a world of difference it made, however I'll need sort out the thermostat housing and rad hose better as it blew the hose off on a hard run and made one helluva mess.

Short clip with the bigger pulley.

The belt is a Gates 6pk1190 i couldn't get the heavy duty or rpm blower belt in that size so it's just a standard belt.

The thermostat housing has only got a very small lip almost nonexistent and doesn't go around the full 360 degree, ill take a few pics today for you.

mopardude318

Well-Known Member

Short clip with the bigger pulley.

The belt is a Gates 6pk1190 i couldn't get the heavy duty or rpm blower belt in that size so it's just a standard belt.

The thermostat housing has only got a very small lip almost nonexistent and doesn't go around the full 360 degree, ill take a few pics today for you.

WOW!! Very Nice! Excellent work you did! Sounds good.

Last edited:

mopardude318

Well-Known Member

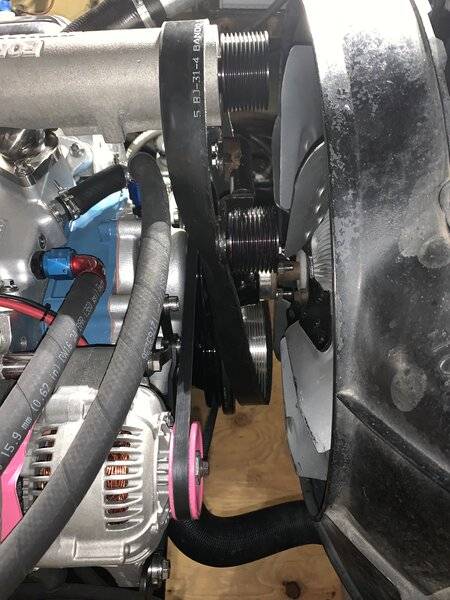

A little more fartin around. I had to space my clutch fan out a 1/2” to clear the 10 rib drive belt. I didn’t like the generic fan spacers available so my brother made one on a lathe at work for me.

mopardude318

Well-Known Member

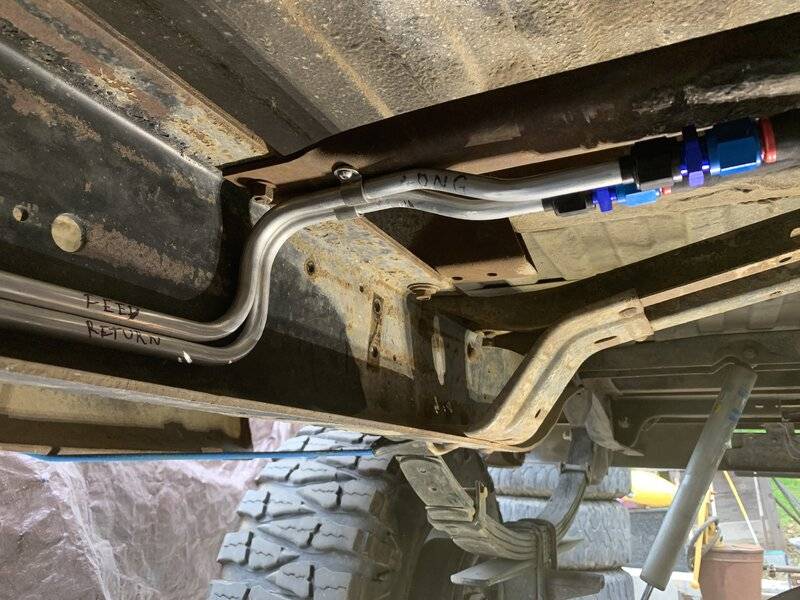

Im using an Aeromotive in tank pump and a universal floatless sending unit. Got some of the fuel lines made. Half way there. I wanted to install the motor this Sunday but we got rain for a week. Would have liked to be driving by Christmas…need to order more fittings. Not the greatest at forming line but this will do, just want it done. Good enough.

mopardude318

Well-Known Member

Sick as a dog and laid up in bed for a week but I had to do SOMETHING! Took me the better part of the afternoon.

MiradaMegaCab

Well-Known Member

LOL Nice work on the fuel lines, but what was so bad about them that compelled you to write on them? LMAO

DARTGAME

SuPeRcHaRgEd

Dig the smug pot heater! Diesel fuel? Looking good.

mopardude318

Well-Known Member

Yes it is diesel! I love it works great!Dig the smug pot heater! Diesel fuel? Looking good.

mopardude318

Well-Known Member

Well after a few late night runs working on it till 1am on the weekends I finally got it running for a quick video.

turbodart68

Well-Known Member

Well after a few late night runs working on it till 1am on the weekends I finally got it running for a quick video.

Wow this turned out so good!

DARTGAME

SuPeRcHaRgEd

Nice! Sounds good. It’s ready for spring fling!

Well after a few late night runs working on it till 1am on the weekends I finally got it running for a quick video.

mopardude318

Well-Known Member

Okay! Runs and drives excellent! Pretty damn good power! Revs quick! LOL.

I’m having blower belt issues… the damn thing comes undone. Blows it right off of there. Need to come up with some better belt tensioner or something. I think it’s running out of tension under high RPM. 6,000 seems to do it. I can’t be driving around like a grandma.

Not sure how to remedy this yet.

@MiradaMegaCab

I’m having blower belt issues… the damn thing comes undone. Blows it right off of there. Need to come up with some better belt tensioner or something. I think it’s running out of tension under high RPM. 6,000 seems to do it. I can’t be driving around like a grandma.

Not sure how to remedy this yet.

@MiradaMegaCab

MiradaMegaCab

Well-Known Member

Then unbolt the “tensioner” from the “tensioner bracket” (part on the right in the pic) and then reassemble with the tensioner as tight as you can manage using the “multiple adjusting/positioning holes. I sort of get the tensioner on a 45* angle (8:00 position) at first, installing only one of the Allen Head Screws (the one on the right (DS) first.

Then pull the tensioner up (the single bolt will give you some leverage) forcing pressure on the belt. Install the second Allen Head Screw. Tighten both up.

Loosen the “spring tension nut”, backing that all the way out. Double nut it at the end or (if your threaded shaft has a hole in it, install a cotter pin and back the nut out, until it rests right up against the cotter pin).

This should give you maximum spring pressure against the belt. Let her run for a bit and check to see that there should be at least 1/4” of “free play” on the tensioner (kinda contradicts the above instructions) but if the belt is new, it’ll stretch out a little bit at first.

You can take apart the tensioner and add a few washers to increase the spring tension too.

I’m assuming your pulleys are running true and wobble free.

Rat Bastid

Dunamis Metron

Im using an Aeromotive in tank pump and a universal floatless sending unit. Got some of the fuel lines made. Half way there. I wanted to install the motor this Sunday but we got rain for a week. Would have liked to be driving by Christmas…need to order more fittings. Not the greatest at forming line but this will do, just want it done. Good enough.

View attachment 1715835697

View attachment 1715835698

View attachment 1715835699

View attachment 1715835700

View attachment 1715835701

View attachment 1715835702

View attachment 1715835703

View attachment 1715835704

View attachment 1715835705

View attachment 1715835706

@PNWsasquatch

-