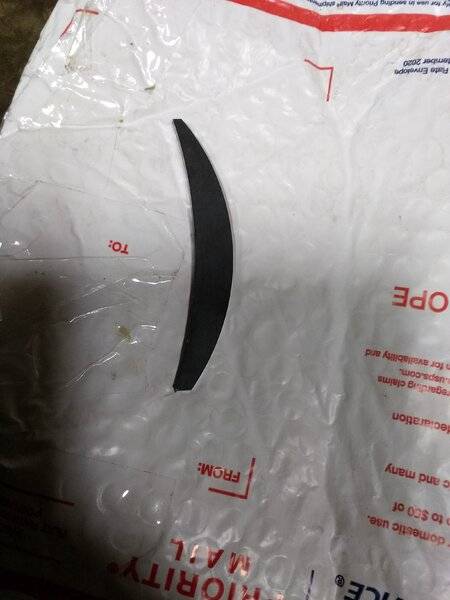

I purchased a firm feel reinforcement kit. It comes with no instructions. I believe I figured out where all the pieces go except for this little one. Does anyone have a clue? I'm guessing it goes to the rear of the steering box mount

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Firm feel k frame reinforcement

- Thread starter PWdart

- Start date

-

There aren’t any instructions. That piece does go between the steering box mount and the K frame, it’s mostly shaped like the area it fits into. When I did the two K’s I’ve done I left that piece out. It didn’t fit either one particularly well and would have required some reshaping. On the K’s I did a double row weld filled the gap quite well, and was faster than making that piece fit.

I’ll see if I can dig up a picture of the area in question.

I’ll see if I can dig up a picture of the area in question.

There aren’t any instructions. That piece does go between the steering box mount and the K frame, it’s mostly shaped like the area it fits into. When I did the two K’s I’ve done I left that piece out. It didn’t fit either one particularly well and would have required some reshaping. On the K’s I did a double row weld filled the gap quite well, and was faster than making that piece fit.

I’ll see if I can dig up a picture of the area in question.

Jim Lusk

Well-Known Member

I put their kit on one k-member. Didn't seem to be worth the money, in my opinion. Pieces didn't fit well. Others I have just made the pieces myself. I weld the pin tubes from the inside with an access hole cut in the bottom.

The Firm Feel kit is probably a little expensive for what it is. It does save a decent amount of time though compared to making all the pieces yourself, so it really just comes down to what you’d rather do.

I bought the Firm Feel kit I used for the first K I did second hand. When I did the second K I just made my own pieces. I think the end result is about the same. I probably wouldn’t buy another kit myself, but if you’re only doing one and don’t want to buy a bunch of metal and make the patterns for all the pieces it’s not a bad idea.

I bought the Firm Feel kit I used for the first K I did second hand. When I did the second K I just made my own pieces. I think the end result is about the same. I probably wouldn’t buy another kit myself, but if you’re only doing one and don’t want to buy a bunch of metal and make the patterns for all the pieces it’s not a bad idea.

my68barracuda

Well-Known Member

I think that Firm Feel has some good products, but they really cheap out on the K frame kit. Agree no instructions. I called their tech line. Eventually got a person on the phone to kind of walk me through where the pieces go. How hard would it be for them to provide a single page with photos and basic instructions.I purchased a firm feel reinforcement kit. It comes with no instructions. I believe I figured out where all the pieces go except for this little one. Does anyone have a clue? I'm guessing it goes to the rear of the steering box mountView attachment 1715822801

Once I saw exactly what I had and how poor the pieces actually fit when placed in their proper positions, I felt I should have saved my $$ and just made my own.

Jim, do you have one of your youtube videos showing where you reinforce the K frames? Thanks.I put their kit on one k-member. Didn't seem to be worth the money, in my opinion. Pieces didn't fit well. Others I have just made the pieces myself. I weld the pin tubes from the inside with an access hole cut in the bottom.

Please make sure to reply to this, or send me a message so I'll know. Thanks.

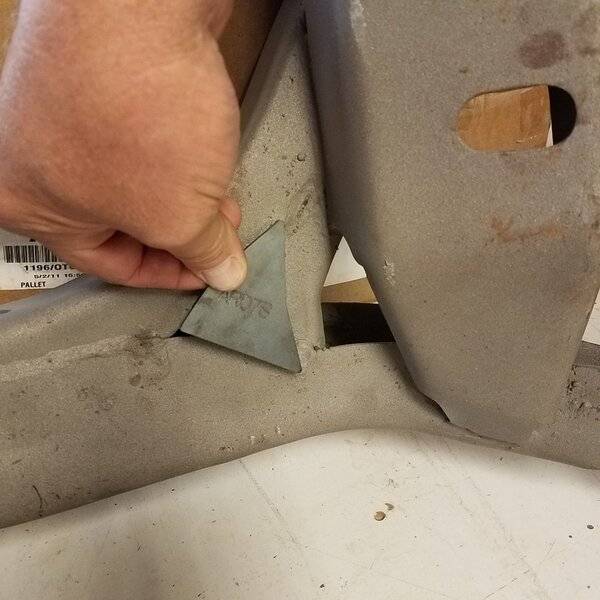

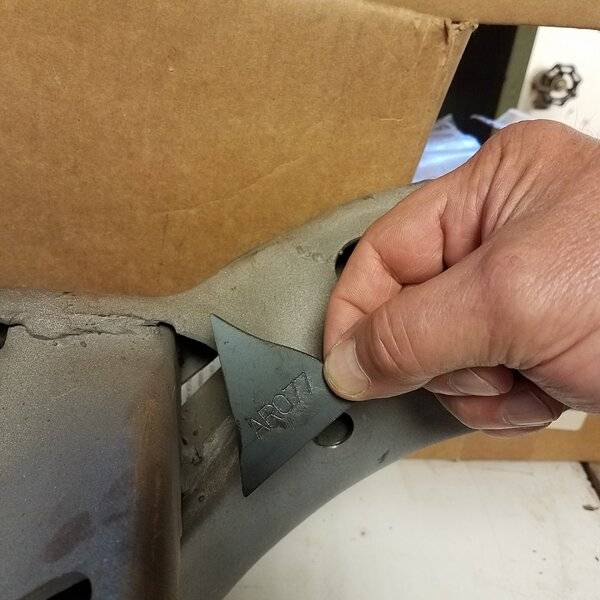

I'm local to firm feel. Back when you could just stop by to buy stuff, I got this reinforcement kit and had them show me where everything went on a spare K-frame they had lying around. Here are the photos, in case they can help someone. I don't have any more details than this, the kit is still sitting on a shelf awaiting installation.

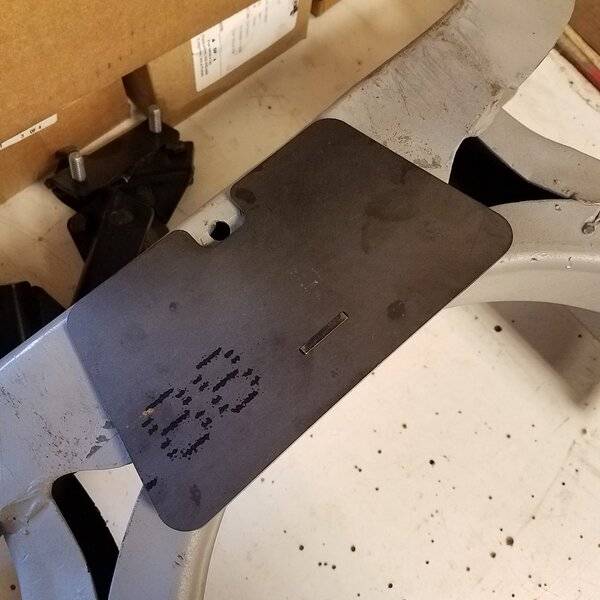

And here are the last couple of pics. The flat plate has a small ridge that goes facing the K-frame.

Thanks for the great reply with pictures. That’s the place I thought it would go. Seems to be a natural fitI'm local to firm feel. Back when you could just stop by to buy stuff, I got this reinforcement kit and had them show me where everything went on a spare K-frame they had lying around. Here are the photos, in case they can help someone. I don't have any more details than this, the kit is still sitting on a shelf awaiting installation.

View attachment 1715823110

View attachment 1715823111

View attachment 1715823112

View attachment 1715823113

View attachment 1715823114

View attachment 1715823115

View attachment 1715823116

View attachment 1715823117

View attachment 1715823118

Jim Lusk

Well-Known Member

Jim, do you have one of your youtube videos showing where you reinforce the K frames? Thanks.

Please make sure to reply to this, or send me a message so I'll know. Thanks.

Nope, no videos, but I may have some pics. I'll have to go digging for them.

Would the k frame reinforcement kit be for a racing application? The reason I ask is that I will be swapping out my engine this winter from under chassis and was planning to do some k frame strengthening for my street only application. Was going to weld up the seams and add washer at the strut mounts. Any advice is appreciated.

my68barracuda

Well-Known Member

The best advice that I can give is, to get good solid welds the K frame needs to be cleaned inside and out. Remember that chunk of iron has spent decades under the car under the engine. I took mine to a local shop that has a strip tank big enough to submerge stock car and sprint car chassis. The better race teams take the cars down completely in the off season, strip the frames to check the welds for cracks. Short of that, a cleaning in an engine shop hot tank would be a good start, remember you need to get the outside and inside super clean.Would the k frame reinforcement kit be for a racing application? The reason I ask is that I will be swapping out my engine this winter from under chassis and was planning to do some k frame strengthening for my street only application. Was going to weld up the seams and add washer at the strut mounts. Any advice is appreciated.

The strut mounts can use some reinforcement and nothing wrong with welding up the seams, but probably the weakest joint on the K frame is the steering box mount area. As newer-grippier-wider tires are substituted in, getting the steering box area more rigid becomes more important.

Good advice. I have 18's, frame connectors, large sway bars and hd torsion bars so I'm sure there's added stresses with aggressive driving.

jos51700

Green Bearing thread connoisseur

Back in '07, I just sent them my k frame and it came back straighter, stronger, and hornier than w when it left. It's very masculine. Maybe even studly. It weighed 10 pounds more on the return manifest.

It's trick, and made a big difference. My steering box doesn't walk around any more.

They made my k frame swole.

It's trick, and made a big difference. My steering box doesn't walk around any more.

They made my k frame swole.

jos51700

Green Bearing thread connoisseur

Good advice. I have 18's, frame connectors, large sway bars and hd torsion bars so I'm sure there's added stresses with aggressive driving.

The factory k frame was slack even in skinny bias ply applications

Question to all who have reinforced a factory K-member: What is your opinion on the strength of a reinforced factory K-member compared to an aftermarket tubular K-member?

Which would you prefer to use for street use with torsion bar suspension?

I do not have either welding skills or equipment so would have to farm out my factory K-member for reinforcement.

Thanks in advance for your input and info.

Which would you prefer to use for street use with torsion bar suspension?

I do not have either welding skills or equipment so would have to farm out my factory K-member for reinforcement.

Thanks in advance for your input and info.

my68barracuda

Well-Known Member

It’s all only time and money.Question to all who have reinforced a factory K-member: What is your opinion on the strength of a reinforced factory K-member compared to an aftermarket tubular K-member?

Which would you prefer to use for street use with torsion bar suspension?

I do not have either welding skills or equipment so would have to farm out my factory K-member for reinforcement.

Thanks in advance for your input and info.

It is likely that a modern tubular K frame would be stronger and lighter.

However, for what you spend for a modern tube K frame, you could spend that same money on a nice MiG welder and a few hours at a vocational school that teaches welding. And for about the same amount of money spent, you could have: your K frame reinforced, a MIG welder and the skill to know how to use it.

Saying that as a K frame is a great first welding project. Plenty thick so burn through issues will be minimal, and there’s no worry about pretty welds. You do want the weld job to be structurally sound, that is why I recommended some professional instruction.

oi81b4uu812b4

Well-Known Member

And here are the last couple of pics. The flat plate has a small ridge that goes facing the K-frame.

View attachment 1715823120

View attachment 1715823121

View attachment 1715823122

View attachment 1715823122

Looks like Firm Feel needs to use your pictures to make instructions.

Well for sure they could be better done and more clear. I can take a shot at that when I do mine.Looks like Firm Feel needs to use your pictures to make instructions.

Well hopefully you guys can help on a couple of these pieces. Some I think are fairly straight forward. Couple of them, I have no idea. My welding is hit and miss, don't judge me too harshly.

Here's where I'm at,

These ones, I'm not sure how they are oriented and haven't been able to find any references.

"Steering box mount bottom rear"

"Steering box mount front"

I'll be sure to post the picture when it's all said and done for future reference.

Thanks.

Here's where I'm at,

These ones, I'm not sure how they are oriented and haven't been able to find any references.

"Steering box mount bottom rear"

"Steering box mount front"

I'll be sure to post the picture when it's all said and done for future reference.

Thanks.

Well hopefully you guys can help on a couple of these pieces. Some I think are fairly straight forward. Couple of them, I have no idea. My welding is hit and miss, don't judge me too harshly.

Here's where I'm at,

View attachment 1715967836 View attachment 1715967835

View attachment 1715967837

View attachment 1715967838

View attachment 1715967839

These ones, I'm not sure how they are oriented and haven't been able to find any references.

"Steering box mount bottom rear"

View attachment 1715967841

"Steering box mount front"

View attachment 1715967840

I'll be sure to post the picture when it's all said and done for future reference.

Thanks.

You've got the first ones right, the ones you have questions about look like this-

The one that goes below the steering mount looks like this, it may need some trimming and you will need to bend it up at the end that meets the steering box mount. It also matters which corner goes into the K frame so if it fits really poorly trying turning it so a different point goes into the K.

The other steering box mount gets folded corner to corner so the part with the curved edge fits into that curved section of steering mount, then the rest goes down into the corner. Again, with all of these pieces some trimming might be necessary to get them to fit tightly enough. Also, with this one you want to get it tucked in nice and tight, because if it sticks up or sticks back too much it can hit the steering box.

You've got the first ones right, the ones you have questions about look like this-

The one that goes below the steering mount looks like this, it may need some trimming and you will need to bend it up at the end that meets the steering box mount. It also matters which corner goes into the K frame so if it fits really poorly trying turning it so a different point goes into the K.

View attachment 1715967843

The other steering box mount gets folded corner to corner so the part with the curved edge fits into that curved section of steering mount, then the rest goes down into the corner. Again, with all of these pieces some trimming might be necessary to get them to fit tightly enough. Also, with this one you want to get it tucked in nice and tight, because if it sticks up or sticks back too much it can hit the steering box.

View attachment 1715967844

That's making sense. Thank you very much!

-