A bit of Wiring 101

It seems like the official FABO winter project for 2021 is rewiring your car. A lot of folks have been asking wiring questions over the past couple weeks so I thought I'd try a bit of a how-to.

I'm rewiring my 64 Dart wagon after it decided to melt most of the underhood wires into a big mess. I've rewired about a dozen cars over the years, most of them while working at a BMW restoration shop.

Let's start with crimps. A good crimp is the basis of a solid wiring job, and a bad crimp will have you chasing gremlins and tearing out what's left of your hair.

Here's my basic tool kit for crimping Packard 56 style connectors:

From left to right; ratcheting and non-ratcheting crimpers; small, sharp cutters (yep, I call 'em dikes too) and a decent stripper.

And for reference, here are the terminals we're dealing with:

The Packard 56 or double-crimp terminal. The bottom crimp holds the insulated part of the wire, while the top crimp grabs the bare copper.

I'll start by making a crimp with the non-ratcheting pliers. Mine are Mac Tools, they cost about $45 when I bought them sometime in the late 90's. They work on 12 gauge up to about 20 gauge wire, and as you can see in the picture they are designed so the jaws stay parallel when they open and close.

Step 1 is to strip the wire. You only want to remove about 1/8 inch of insulation, like this:

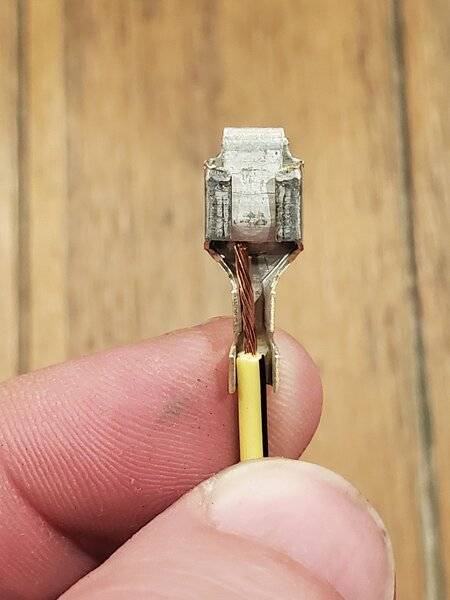

Notice that the insulated part of the wire stops just before the top crimp,, and the exposed copper is just the length of the top crimp.. You don't want a ton of wire hanging out of the top of the crimp like this:

It looks ugly and your boss will yell at you.

And you definitely don't set up the crimp like this:

The advantage to this type of terminal is the bottom crimp into the insulation provides all the strength, allowing the top crimp to just make the electrical connection.

Oh yeah, if your strippers cut the copper strands like this:

Get better strippers. In 18 gauge wire, each one of those strands carries about 15% of the total capacity of the wire.

Anyway, I like to grab the terminal in the crimper first and then insert the wire.

If you look closely you can see the "buttocks" side of the crimper on the left. The open side of the terminal goes toward that side. The buttocks roll the ends of the terminal around and in, grabbing the wire like this:

I chose the 'B' size to make the initial crimp. And to form the crimp onto the bare wire, go with the next size down.

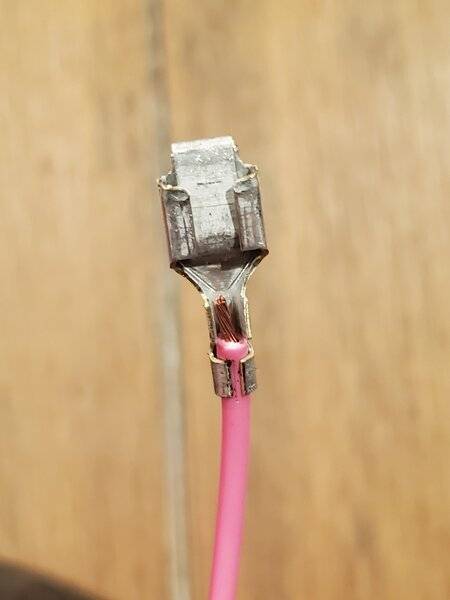

The biggest problem with these pliers is that you have to guess which size will work best for the crimp you are about to make, so you often have to redo the crimp with a smaller size. But eventually, we end up with a good crimp:

It seems like the official FABO winter project for 2021 is rewiring your car. A lot of folks have been asking wiring questions over the past couple weeks so I thought I'd try a bit of a how-to.

I'm rewiring my 64 Dart wagon after it decided to melt most of the underhood wires into a big mess. I've rewired about a dozen cars over the years, most of them while working at a BMW restoration shop.

Let's start with crimps. A good crimp is the basis of a solid wiring job, and a bad crimp will have you chasing gremlins and tearing out what's left of your hair.

Here's my basic tool kit for crimping Packard 56 style connectors:

From left to right; ratcheting and non-ratcheting crimpers; small, sharp cutters (yep, I call 'em dikes too) and a decent stripper.

And for reference, here are the terminals we're dealing with:

The Packard 56 or double-crimp terminal. The bottom crimp holds the insulated part of the wire, while the top crimp grabs the bare copper.

I'll start by making a crimp with the non-ratcheting pliers. Mine are Mac Tools, they cost about $45 when I bought them sometime in the late 90's. They work on 12 gauge up to about 20 gauge wire, and as you can see in the picture they are designed so the jaws stay parallel when they open and close.

Step 1 is to strip the wire. You only want to remove about 1/8 inch of insulation, like this:

Notice that the insulated part of the wire stops just before the top crimp,, and the exposed copper is just the length of the top crimp.. You don't want a ton of wire hanging out of the top of the crimp like this:

It looks ugly and your boss will yell at you.

And you definitely don't set up the crimp like this:

The advantage to this type of terminal is the bottom crimp into the insulation provides all the strength, allowing the top crimp to just make the electrical connection.

Oh yeah, if your strippers cut the copper strands like this:

Get better strippers. In 18 gauge wire, each one of those strands carries about 15% of the total capacity of the wire.

Anyway, I like to grab the terminal in the crimper first and then insert the wire.

If you look closely you can see the "buttocks" side of the crimper on the left. The open side of the terminal goes toward that side. The buttocks roll the ends of the terminal around and in, grabbing the wire like this:

I chose the 'B' size to make the initial crimp. And to form the crimp onto the bare wire, go with the next size down.

The biggest problem with these pliers is that you have to guess which size will work best for the crimp you are about to make, so you often have to redo the crimp with a smaller size. But eventually, we end up with a good crimp: