This is correctJust to clarify, Oil pump is NOT part of the frt cover. Pump and regulator are one piece with a wiring harness clipped in through a hole in back of block.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3.6 Pentastar oil pressure sender woes.....

- Thread starter pishta

- Start date

-

goldduster318

Overzealous Car Modifier

Those oil filter housings/coolers have a lot of problems, my friend's wife has a 2011 Grand Caravan and we changed that this fall. You can complain all you want but that's an easy intake to pull and replace the gaskets. If that oil filter housing/cooler hasn't been replaced, its only a matter of time until it needs one.

In our case, the seals were bad on the bottom and it was seeping oil and coolant. The intake gaskets were also totally flat. This van had about 125k.

In our case, the seals were bad on the bottom and it was seeping oil and coolant. The intake gaskets were also totally flat. This van had about 125k.

pishta

I know I'm right....

Success? Not a drop of oil on the ground, no sign of the pesky CEL light with the new 5W-30 oil. Is this thing that sensitive that it can tell the difference in viscosity? Time will tell, so far so good 40 miles with only new (proper) oil! 130K...So weird......

pishta

I know I'm right....

P0520---NO red oil light.

New 5W-30 oil, new filter, new sensor. No CEL yet.

New 5W-30 oil, new filter, new sensor. No CEL yet.

So the P0520 code is a Koeo test that runs after the engine has been off long enough for the oil pressure to bleed down to 0. It checks to see if the oil sensor is less than .29 volts or more than .71 volts. I don't think the oil is gonna be the problem. See what happens.

pishta

I know I'm right....

So the ECU sends a signal to the sensor after the motor is shut off or possible prior to it being started to see if it returns the correct voltage? could the oil filter cap be the (pressure) problem? Its not cracked, new O-ring...says 25NM torque spec on the little 15/16 hex cap but getting a torque wrench on that is near impossible unless its a crows foot (dont have) or you take the intake plenum hose off. I just tightened it until it bottomed and gave it a little snug but it didnt move after that. Being plastic I didnt use much force on it but I can see its bottomed on the body and there are no signs of leaks at that point. Motor is very clean, never had a leak of anything on this.

So what I’m hearing, is I might want to replace those sensors while I’m in there replacing the filter adapter/housing in our 200?

The computer checks the oil sensor for 0 at key on. If the cap is not leaking it is fine. You did it exactly the way I have done them. Just tighten it till it bottoms out. The oring provides a lot of drag it will not loosen up.

Loggato

Well-Known Member

yeah those intake manifolds are REALLY easy to remove... A little trickier on the RWD applications, but once you know how to fenagle the intake around it's not bad. However it looks like the OP's method worked well too.

The adapter/housing I’m getting doesn’t come with sensors.Both sensors will come in the new adapter/housing

MopaR&D

Nerd Member

Dang wish I saw that when I had to replace the assembly in my mom's 2014 300, aluminum would be much better than plastic. Yes you should replace the sensors and try your best to go OE brand, anything else is a crapshoot.

It was quite a bit easier than I expected to replace the filter/cooler assembly but that car has a pretty big engine bay and it's RWD/AWD with plenty of space to work. I could see the SUVs or transverse-mounted FWD ones being more tricky. Stupid thing to have to fix but at least they made it reasonably serviceable. And boy those plastic intake manifolds are nice, so much lighter, heat-insulating... if someone made plastic intakes for our old carbed V8s I'd try one. I bet the plastic doesn't work well being constantly exposed to gasoline though and the internal surface is smooth which doesn't help keep the atomized fuel in suspension.

pishta

I know I'm right....

My sensor was an Amazon special...(had same results with the old oil) I should have saved the old one! If you could install a 4" male to female standoff tube (in the same NPT thread pitch) into that cooler, you could bring the sensor out from underneath the intake and have it out in the open for the next service. Oil temp not so much as its angles upward. Is the wire They can make plastic any texture internally as long as they can E-weld the 2 halves together (cant do a hollow casting) and plastic is very stable with gasoline. Edelbrock makes a performance intake out of plastic for the Ford Coyote IIRC. Remember MPFI intakes can be smooth as a babies butt internally because the fuel is administered at the end of the runner. It can also be in the shape of Mickey Mouse and still work as its only directing lightweight air, not heavy fuel/air mix that doesnt like turning corners.

pishta

I know I'm right....

Is the plug leads a direct shot to the ECU? I can trace those out. I think the ECU is right on the transmission under the battery, unless its hidden under the glovebox.

Dorman just came out with them recently I believe. We have no intention of selling the car anytime soon, so figured may as well spend more once and get the aluminum one, and hopefully never have to mess with it again.Dang wish I saw that when I had to replace the assembly in my mom's 2014 300, aluminum would be much better than plastic. Yes you should replace the sensors and try your best to go OE brand, anything else is a crapshoot.

It was quite a bit easier than I expected to replace the filter/cooler assembly but that car has a pretty big engine bay and it's RWD/AWD with plenty of space to work. I could see the SUVs or transverse-mounted FWD ones being more tricky. Stupid thing to have to fix but at least they made it reasonably serviceable. And boy those plastic intake manifolds are nice, so much lighter, heat-insulating... if someone made plastic intakes for our old carbed V8s I'd try one. I bet the plastic doesn't work well being constantly exposed to gasoline though and the internal surface is smooth which doesn't help keep the atomized fuel in suspension.

Last edited:

pishta

I know I'm right....

WTF....CEL is still on with same code. Pulled the intake (not that hard, thanks for the heads up) and found 3 inches of pink sludge in the intake valley. Must have been 3 bottles of stop leak in there. Bought new cooler gaskets (5 o rings) and found there is a plate under the OEM housing that holds 2 of the O-rings. It seems like its loose? Both clips are still clipped but you can wiggle it slightly as if there is another O-ring under this plate. It goes up to the metal plate cooler. Anyway, all O-rings are replaced and probing the sensor wiring with KOEO , I get 2.67 volts!!! WTF. I thought it was supposed to be under .67. I took an allen wrench and gently pushed the diaphragm in on the pressure sensor while it was getting 5 volts in the harness and the 2.67 volts did not change (I thought it would change with a little pressure on the diaphragm?) I put it all back together and the code actually cleared for the next 3 start ups and runs and then it tripped again with same 520 code and 520PD (pending?) I think I got a bad sensor. Anyone agree with me? full 4.97 volts to sensor on power wire.

pishta

I know I'm right....

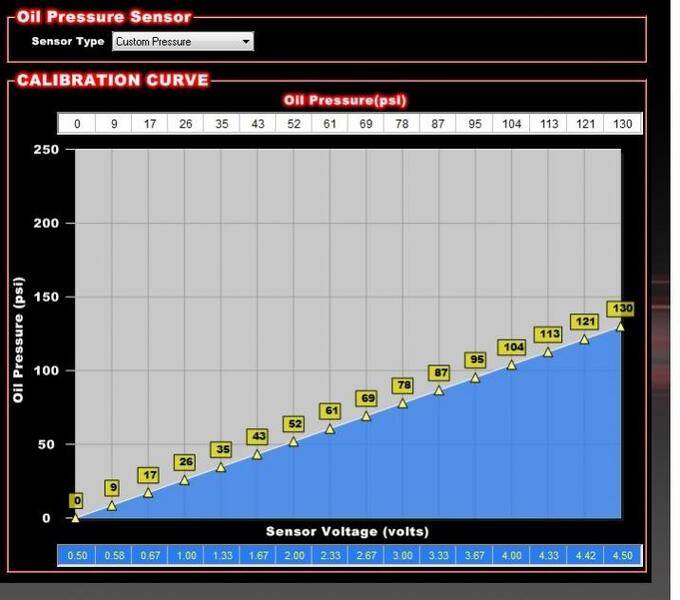

GM LS oil pressure graph for reference. Same output for a Mopar sourced sensor?

pishta

I know I'm right....

What are the 2 plugs in the valley that seem to go straight down into the block on a 3.6? The one on the left had a broken plug retainer. I had to zip tie it so it would stay on to its male end....What are they to?

<< found them.....knock sensors! >>>

Mine had so much crap in that valley I didnt even see these until I vacuumed out all stop leak grit, oil and coolant that came out the cooler when I lifted it.

<< found them.....knock sensors! >>>

Mine had so much crap in that valley I didnt even see these until I vacuumed out all stop leak grit, oil and coolant that came out the cooler when I lifted it.

Last edited:

pishta

I know I'm right....

Victory! I went to the boneyard and grabbed a crusty one off a wrecked '06 Commander (right in front on block), plugged it in and got more or less correct voltages in circuit, ie .26 or something KOEO. Drove it a few miles...no codes. So the OEM stuff off a junker is better than the new aftermarket stuff....again!

Maybe a word of advice: When you buy a new car or truck, maybe the first thing you should do to the motor is unplug every weather-tight sensor one at a time and put some silicone grease in each one so they actually come off when you need them to instead of snapping the plug retention or breaking the F'n lock tabs! Some of these are near impossible to unplug without a pair of pliers.

Maybe a word of advice: When you buy a new car or truck, maybe the first thing you should do to the motor is unplug every weather-tight sensor one at a time and put some silicone grease in each one so they actually come off when you need them to instead of snapping the plug retention or breaking the F'n lock tabs! Some of these are near impossible to unplug without a pair of pliers.

MopaR&D

Nerd Member

Victory! I went to the boneyard and grabbed a crusty one off a wrecked '06 Commander (right in front on block), plugged it in and got more or less correct voltages in circuit, ie .26 or something KOEO. Drove it a few miles...no codes. So the OEM stuff off a junker is better than the new aftermarket stuff....again!

Maybe a word of advice: When you buy a new car or truck, maybe the first thing you should do to the motor is unplug every weather-tight sensor one at a time and put some silicone grease in each one so they actually come off when you need them to instead of snapping the plug retention or breaking the F'n lock tabs! Some of these are near impossible to unplug without a pair of pliers.

I find myself going to the junkyard more for bigger replacement parts like alternators, starters, P/S pumps, brake boosters/master cylinders... The OE factory parts with 100k+ miles on them are almost always better quality and just plain work better than the parts-store garbage even when "new". Dorman makes good stuff I suppose but the rest is a total crapshoot, usually breaks conveniently just after the end of the warranty period.

Also I feel your pain about the electrical connectors, I think there is a special pair of pliers you can get specifically for disconnecting those; makes it much easier to save the lock tabs from breaking. I broke one or two then was just super delicate and careful with the rest. This modern car plastic stuff is bullshit lol.

Hellrats

Just another dumbass

Sorry, a little late to the party. I have been working 12 hours a day six days a week. Money is damn good but getting tired. Yes, the valley will get filled with everything and it is deep. Anything that leaks in the middle ends up there. They are still a good engine but they do not like dirty oil. These new engines have a lot more going than the old stuff did. Glad you got it sorted out.

-