Help with front end alignment

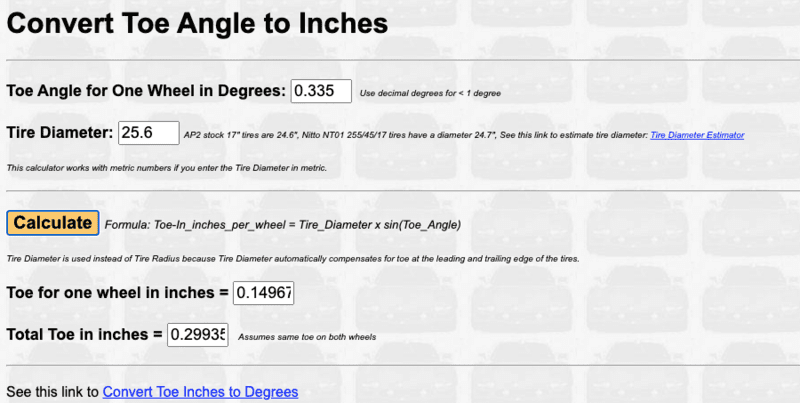

Yeah but he doesn't have .25° of toe. He has .35° on one side, .32° on the other, and a total toe of .67°. So if you put in .335° (this calculator splits it per wheel)

You get .299" of toe, which is a little less than 5/16". This is the toe setting now, not what it was when it wore the inside of the tires. I bring attention to it because that alignment it totally screwed up, and that's the "fixed" version. This shop is in over it's head.

The toe setting is the only thing that will wear radials that fast without being ridiculously obvious. Even a camber in the 3° range wouldn't wear tires that fast, and it would look like this...

Torsion bar hex goes into a socket on the LCA. But otherwise, yes. The tubular LCA's, because of their narrow profile, can hang down further on the pin than a factory LCA. So if you follow the factory instructions on LCA installation and let the LCA hang down, the factory LCA hits the K frame. The QA1 LCA can hang literally straight down. What that does is it makes more than one hex flat available for the LCA position. So you can mis-clock the LCA on the torsion bar. It's almost impossible to do with the stock LCA's, but it's actually pretty easy to do with the QA1's. I've done it. That could explain why the torsion bar adjusters are so different, one of the LCA's is installed a hex flat off from the other one.

But that DOESN'T explain any of your other issues, as you've described them. Do you have a picture of where the torsion bar is hitting the frame?

The loss of alignment could have been from the original eccentric bolts and washers. There were aftermarket eccentrics that weren't threaded far enough down the bolt, so, they tightened up before they actually clamped the UCA in place. They eccentrics could then move, and you'd lose your alignment. It could be what you had, your tech then overtorqued the bolts trying to lock it down and stripped the eccentric washers. Or maybe the tech just completely hammered the eccentrics first and that's why it moved.

Either way they sent you on your way with a completely unacceptable alignment. You could do better yourself just eyeballing it and using a tape measure.

Yeah but he doesn't have .25° of toe. He has .35° on one side, .32° on the other, and a total toe of .67°. So if you put in .335° (this calculator splits it per wheel)

You get .299" of toe, which is a little less than 5/16". This is the toe setting now, not what it was when it wore the inside of the tires. I bring attention to it because that alignment it totally screwed up, and that's the "fixed" version. This shop is in over it's head.

The toe setting is the only thing that will wear radials that fast without being ridiculously obvious. Even a camber in the 3° range wouldn't wear tires that fast, and it would look like this...

Torsion bar hex goes into a socket on the LCA. But otherwise, yes. The tubular LCA's, because of their narrow profile, can hang down further on the pin than a factory LCA. So if you follow the factory instructions on LCA installation and let the LCA hang down, the factory LCA hits the K frame. The QA1 LCA can hang literally straight down. What that does is it makes more than one hex flat available for the LCA position. So you can mis-clock the LCA on the torsion bar. It's almost impossible to do with the stock LCA's, but it's actually pretty easy to do with the QA1's. I've done it. That could explain why the torsion bar adjusters are so different, one of the LCA's is installed a hex flat off from the other one.

But that DOESN'T explain any of your other issues, as you've described them. Do you have a picture of where the torsion bar is hitting the frame?

The loss of alignment could have been from the original eccentric bolts and washers. There were aftermarket eccentrics that weren't threaded far enough down the bolt, so, they tightened up before they actually clamped the UCA in place. They eccentrics could then move, and you'd lose your alignment. It could be what you had, your tech then overtorqued the bolts trying to lock it down and stripped the eccentric washers. Or maybe the tech just completely hammered the eccentrics first and that's why it moved.

Either way they sent you on your way with a completely unacceptable alignment. You could do better yourself just eyeballing it and using a tape measure.