Please Help identifying underhood components

H'm I see that link to the '76 wiring pdf is now dead. I tried to attach the pdf to this post. Sorry that failed.

Gages cost money - even cheap ones. Technology now allowed a fairly cheap remote shunt gage which maybe saved some heavy wiring. The percentage of American drivers who were familiar with and had learned to use gages was less and less. Ammeters can be confusing to those who are not familar with them. There isn't just one correct position for the needle. The driver needs to understand that the normal position depends on the situation.

Another reason may have been that more and more electtrical stuff was being added to both the engine and for the passengers. Electric assisted chokes, warning buzzers, rear window defrost, A/C etc.

Fusible links are not in themselves a good or bad thing. Mostly they were used to protect the downsteam wires and components from a battery short to ground.

When cars needed hardly any electrical power to run the engine and accessories, having just one link between the battery and everything else made sense.

In this arrangement, the alternator output could flow direct to the main splice without going through the potential source of resistance of a fusible link.

Lets say the car was just started, so the battery needs a recharge and the driver turns on the headlights, wiper, and heater fan.

Since the car was just started, the engine will be spinning around 1700 rpm. At that rpm its probably capable of 40 amps at 14.2 Volts.

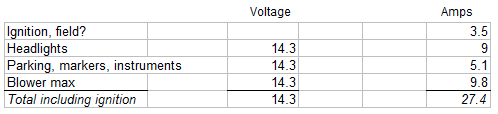

Here's my measurements of current flowing to these items on my '85 Grand Wagoneer

That's without the brake lights on. So lets add 2.5 amps for brake lights and 10 amps for recharging the battery.

Total alternator output then is 40 amps at 14.3 Volts.

On the standard pre-76 wiring, that 40 amps flows directly to the main splice through either 12 gage or 10 ga wire.

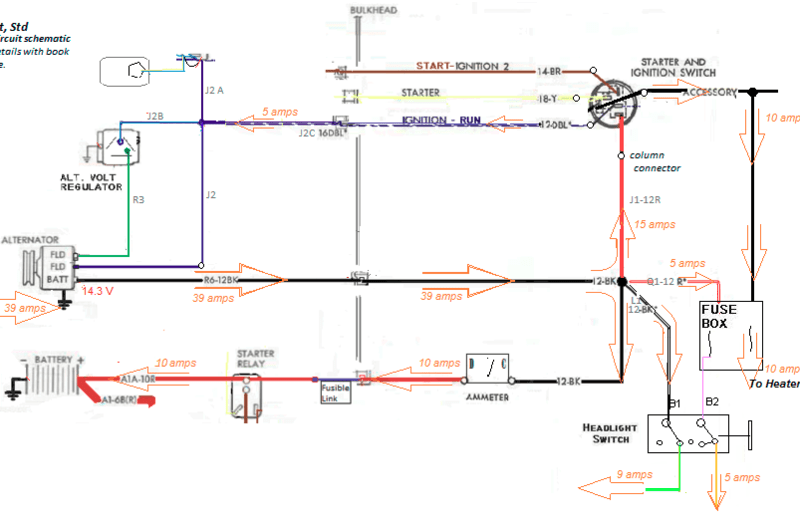

On a diagram current flow would look like this

The major source of resistance to that much flow will be the connectors. Its really pushing the limits of the pushon (Packard 56/58 type) terminals. But imagine if there was also a section of 16 gage wire in that R6 line!

Another moral of the story is let the battery recharge for a minute before turning all the other stuff on.

However the connections could also be addressed as a design weakness. One solution was to use better connections. Another solution is to split the flow path before the connections.

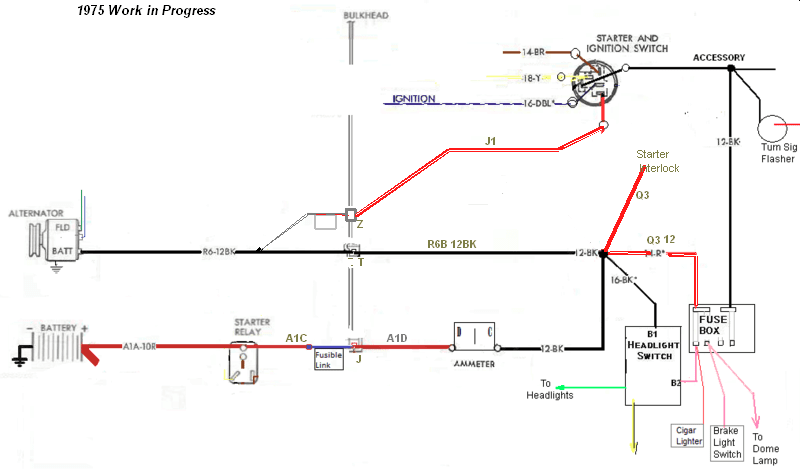

We can see this in at least some 1975 models.

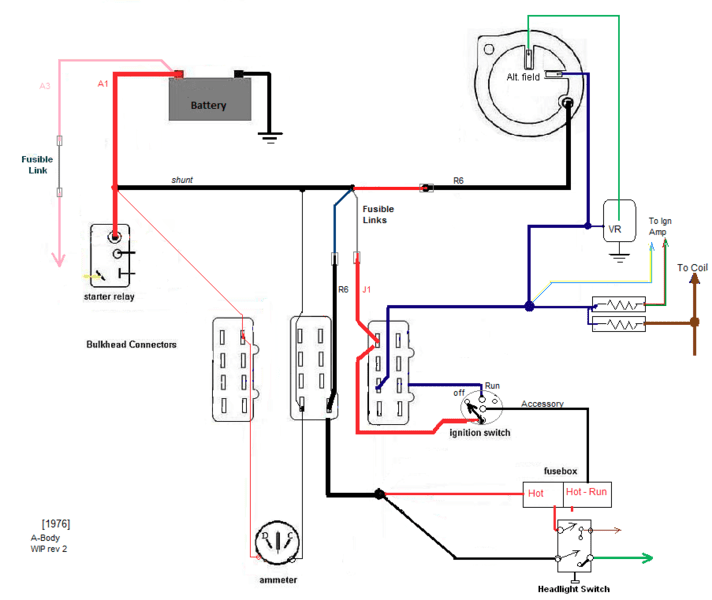

And carried further in 1976.

However be aware that the '76 links are spliced in, so they are harder to replace.

Also, that the currents going to ignition switch and fuse box will be constantly be going through those links. Those links are the smallest wires in the main circuits so we don't want to exceed their capacity. Since youyr not adding anything you should be OK. Still its best to let the battery recharge a bit before turning on heater fan a/c etc. Its also still a good idea to watch the ammeter during recharging if the battery has been really run down. If its pegging (at 40 amps), that's too much current.

H'm I see that link to the '76 wiring pdf is now dead. I tried to attach the pdf to this post. Sorry that failed.

I can only take guesses here. There may be an explanation in the Master Technicians Conference, and if mymopar has fixed their server issues we can look through there.

Gages cost money - even cheap ones. Technology now allowed a fairly cheap remote shunt gage which maybe saved some heavy wiring. The percentage of American drivers who were familiar with and had learned to use gages was less and less. Ammeters can be confusing to those who are not familar with them. There isn't just one correct position for the needle. The driver needs to understand that the normal position depends on the situation.

Another reason may have been that more and more electtrical stuff was being added to both the engine and for the passengers. Electric assisted chokes, warning buzzers, rear window defrost, A/C etc.

If you have a factory 50 amp that is great.

Fusible links are not in themselves a good or bad thing. Mostly they were used to protect the downsteam wires and components from a battery short to ground.

When cars needed hardly any electrical power to run the engine and accessories, having just one link between the battery and everything else made sense.

In this arrangement, the alternator output could flow direct to the main splice without going through the potential source of resistance of a fusible link.

Lets say the car was just started, so the battery needs a recharge and the driver turns on the headlights, wiper, and heater fan.

Since the car was just started, the engine will be spinning around 1700 rpm. At that rpm its probably capable of 40 amps at 14.2 Volts.

Here's my measurements of current flowing to these items on my '85 Grand Wagoneer

That's without the brake lights on. So lets add 2.5 amps for brake lights and 10 amps for recharging the battery.

Total alternator output then is 40 amps at 14.3 Volts.

On the standard pre-76 wiring, that 40 amps flows directly to the main splice through either 12 gage or 10 ga wire.

On a diagram current flow would look like this

The major source of resistance to that much flow will be the connectors. Its really pushing the limits of the pushon (Packard 56/58 type) terminals. But imagine if there was also a section of 16 gage wire in that R6 line!

Another moral of the story is let the battery recharge for a minute before turning all the other stuff on.

However the connections could also be addressed as a design weakness. One solution was to use better connections. Another solution is to split the flow path before the connections.

We can see this in at least some 1975 models.

And carried further in 1976.

However be aware that the '76 links are spliced in, so they are harder to replace.

Also, that the currents going to ignition switch and fuse box will be constantly be going through those links. Those links are the smallest wires in the main circuits so we don't want to exceed their capacity. Since youyr not adding anything you should be OK. Still its best to let the battery recharge a bit before turning on heater fan a/c etc. Its also still a good idea to watch the ammeter during recharging if the battery has been really run down. If its pegging (at 40 amps), that's too much current.

Probably. Its still a long route with many connections from the alternator to the headlights and the '76 diagram still shows only 18 ga wire to the lamps. So connecting directly to the alternator takes some load off the wiring.