I sold a lot of those Fireball cams back in the 70's. $49.95 was cheap performance.I have been out of the Loop for some time. In 87' I bought a Purple Direct Connection cam from them with the 68' manual specs to go into my 69' 4-speed Dart Swinger that I still have (see photo). I also have a DC cam (auto specs) in my Van. Both run well. Hard to compare, due to the apps. Just last year I tossed a good Crain cam "Fireball" cam that I had sitting around 35 years. My Bad!!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Replacement 68 340 four speed cams

- Thread starter FWDLK Frank

- Start date

-

Dartswinger70

Well-Known Member

I would be in for an exact reproduction of that cam at the aforementioned price. I know the price is a little high but it would also be a rare and exclusive cam to have in my engine...

So my question about the repost #3 from the "How to Articles" is, where did this info come from and is this the '68 340 4 speed cam?

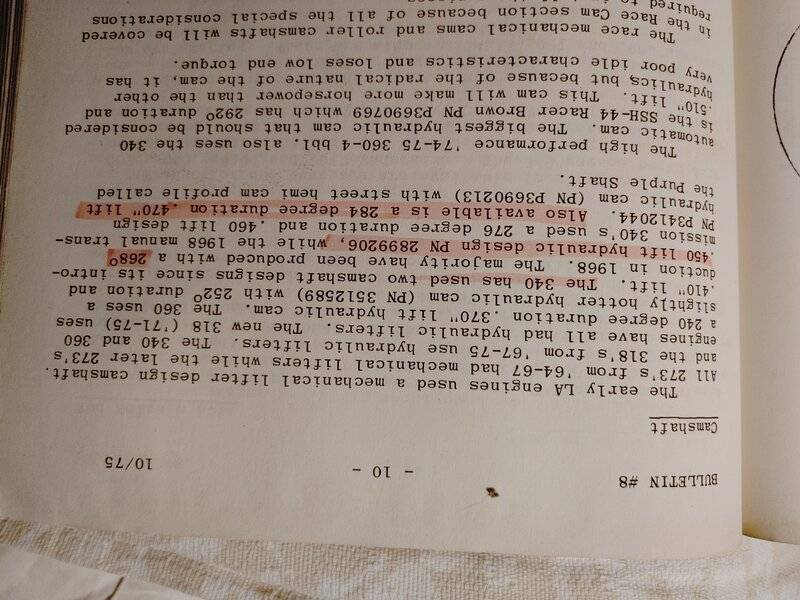

Found this and it relates to the Service manual. This also shows the '68 340 automatic cam. Yep, I'm still looking.

*68 340 only

Automatic-equipped Barracudas employ a hydraulic cam with 268/276-degrees advertised duration and .429/.444-inch lift. With the four-speed, there's 276/284-degrees duration and .444/.453-inch lift. Both cams use shaft-mounted 1.50:1 rocker arms and connect to the crank via a double-roller timing chain.

*68 340 only

Automatic-equipped Barracudas employ a hydraulic cam with 268/276-degrees advertised duration and .429/.444-inch lift. With the four-speed, there's 276/284-degrees duration and .444/.453-inch lift. Both cams use shaft-mounted 1.50:1 rocker arms and connect to the crank via a double-roller timing chain.

Last edited:

scatpackbee

Well-Known Member

I would be interested in a ‘68 340 4 speed cam.

Any updates on this project?

Any updates on this project?

Last edited:

Krooser

Building Chinese Free Engines since 1959...

All this discussing has me waxing nostalgic about my time working at Mopar dealers from '68-'72. I was surprised how easy a fast 1-2 shift on a 340 Baccaruda/Dart can break a u joint on a test drive!

That's what this thread was about, the 68 4 speed cam. That's what Ken at Oregon has on file. I think it's 2 degrees off.

I am more interested for one please make one for me.

Swinger 340

Well-Known Member

Does anyone know why the 68' manual 340 cam only came in that year and not any other in the 4-speeds. I did install a 68' 340 manual cam in my 69' Dart when I rebuilt it in 87'. It runs great as my other 340 (70') with an automatic cam. I think, possible being a non - slip clutch (manual) it could run a little higher RPM engaged.

Don't know the answer to that, but I'm more inclined to wonder why they stopped using it.Does anyone know why the 68' manual 340 cam only came in that year and not any other in the 4-speeds. I did install a 68' 340 manual cam in my 69' Dart when I rebuilt it in 87'. It runs great as my other 340 (70') with an automatic cam. I think, possible being a non - slip clutch (manual) it could run a little higher RPM engaged.

PRH

Well-Known Member

My guess would be so they only had to produce one version of the engine....... and use it in either stick or auto.

Economics.

Economics.

Would've been nice if they opted to keep the "radical" cam for both auto. and 4 speed.My guess would be so they only had to produce one version of the engine....... and use it in either stick or auto.

Economics.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,870

- Reaction score

- 12,214

These cams run best in High-Compression engines, or in clutch cars because of the loss of cylinder pressure at low rpm. Neither can hardly be called "radical". To get the numbers, they have really long clearance ramps.

For the 268s;

The wide LSA (114) allows the rpm to hang on at the top, I have seen dyno curves where the power plateau is about 1000rpm, which is huge! But it comes at the expense of absolute power.

For the 268s;

The wide LSA (114) allows the rpm to hang on at the top, I have seen dyno curves where the power plateau is about 1000rpm, which is huge! But it comes at the expense of absolute power.

Not throwing the candy on the ground, just saving it for myself/later time. When I posted a wanted ad this cam a year ago... [WANTED] - 68 340 4 speed Cam

There was quite a bit of response and then a debate of whether or not the Oregon cam was 100% correct or not to the point where a moderator had to get control of the thread and delete the commentary. So, since I didn't find what I wanted on fabo, I decided to keep looking. I happen to know a retired Chrysler engineer and when I spoke with him about it, he contacted his fellow retired engineers. It just so happened one of his friends was in small blocks and he had this cam, another engineer had the blue prints. Both of them were very humble and sold me what I now have for a reasonable price... initial investment. Jim at Racer Brown is a friend of mine and we discussed making a run of these. To do an exact copy, masters need to be made and there's a cost associated with that. If Jim knew with certainly that he'd sell 50-100 or so of these in a short time I'm sure the cost of the masters could be written off...but I'm not going to put a friend's money on the line for an uncertain venture. This is why I said I would front the money for the masters, not to mention my original investment for the cam/blueprints. All I was asking for is a list of committed buyers. If I seen the list was 50-100 strong and all of the members had good feedback/integrity, perhaps the price could be lowered, but again, I'm taking the risk. If close enough is good enough for everyone, so be it, enjoy what's close enough for the price you want. I'm not going to debate specs/knock another cam manufacturer/speak poorly of anyone's manufacturing processes, that's for the purchaser to decide. More often than not in this hobby, making replacement or reproduction parts is not worth the time unless you are a well established company with a shop full of equipment. My goal was to take care of a want that I had. I thought with my find maybe others would want the same and perhaps over time, I would possibly break even. From the responses I read, it would appear the majority is happy with what's available so this is not a venture worth my efforts. I'm also not going to put a friendship with Jim on the line if no one is interested. Jim has a well established company but you all need to understand, for the most part, he's basically a one man operation and works literally every day to keep up with orders. Since there is no interest, the cam and the blueprints will sit on a shelf in my garage...maybe someday there will be enough interest to make it worthwhile. I digress.

Like your idea of making them to factory specs (blueprint) setting up masters to do it. Then they will have the factory base circles and use the stock length mopar pushrods.

The regrind cams to the 340 4spd specs are going to have smaller base circles and will need the push rod lengths looked into.

For someone who wants a blueprinted 340 4spd cam, your price is not that bad. Was about the same price as the last of the Mopar Performance 340 cams were costing when they used to be available at the end of their production. Now no longer available.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,870

- Reaction score

- 12,214

They are not ONE of the best, they are THE best .... but only because MaMopar never installed a bigger or better cam, and as you know the 340 only ran from 68 to 73.I'm "cam"inally challenged, so to speak/slur. These were one of the "best " sb factory mopar cams correct? My 340 build will have oem 273 adjustable rockers and I would like to go solid flat tappet.

By doing this, how(if any) will this alter the cams "performance"? Will the cam specs need changing to a solid?

Thanks

By today's standards, there are lots of better grinds; especially if you plan to run headers, and even more especially if you don't have the cylinder pressure to support these wide LSAs.

As to hydro versus solid;

Hydraulic lifters present to the valve springs as very heavy, and the higher you rev then, inertially they just get heavier and heavier. Eventually the springs give up. At the other end; the ramps have to be Looooong to accelerate the heavy buggers without squeezing the oil out of them. And to set them down easy without bouncing.

So when you look at the Advertised spec, you might see 268 degrees.

But, firstly, this number is ethereal; in that some grinders measure this at .008 tappet rise while others at .006 , and others at whatever they want. There are no standards for advertised numbers.

So then, at .008 Tappet rise, the valve is still open, say .012inch with a true rocker arm ratio of 1.50.

What that means is that, your engine cannot make cylinder pressure until that .012 disappears to zero. And unless you know where zero is, this could be 10/14/18 degrees later. So then, seat to seat, of a 268* cam could be double the run-off room (say 14 x 2=28) plus the advertised 268 =296 degrees... or more.

Why do you care?

Because like said, your engine cannot start making pressure until the intake valve closes. In a short stroke engine, with a long-period cam, the EFFECTIVE Stroke computed from the closed position of the valve, can be very very short.

For a streeter this is bad because in order not to suffer a huge loss of bottom end power/torque, you have to increase the compression ratio to get the cylinder pressure up to a useful level. But to use today's gas, you can only go so far; Especially with iron heads.

Solid lifters, on the other hand are much lighter, and so ALL ramps can be faster and YOU, by setting the lash, determine EXACTLY when the intake valve actually closes, and by so doing, have exact control of the Effective Stroke.

However, because of the lash, you lose an amount of lift equal to the lash.

Furthermore, by adjusting the lash smaller or greater, you are also determining the advertised duration..... AND the 0.050 simultaneously.

This means that if you stick a 268 hydro cam into your engine and run it with solid lifters and lashed;you actually end up with a cam that is smaller than what you thought. Some say, about one size smaller.

This means, you gotta order a bigger solid cam to equal the smaller hydro cam.

The up-sides of this are;

1) Principally, that the lighter solid lifters will rev to a higher rpm with the same springs. and

2) the cam can be ground with faster acceleration rates, for more airflow potential at any given position, and

3) YOU have some control of the actual installed cam size by varying the lash.

The downsides are;

1) periodic lash adjustment, and

2) possibly a shorter cam life.

Now here is my opinion/ my experience; having run three hydraulic cams, namely; 270/276/292 intake degrees, in my Hi-compression 367;

IMO for a streeter, if you have the luxury of high cylinder pressure; just run a hydro.

But if you are stuck with a low-pressure engine, a solid lifter cam may, I say may, get you a tiny bit more all-round performance . If you go too big, you will suffer the same low-pressure/low-rpm problem, and the difference, typically,

is only one cam size.

And finally, you can get some pretty good results, by running a too-big hydro cam, and lashing it, lol. As we saw above, a 268 advertised cam might actually be 296* seat to seat. but if you lash it up, you might turn it into a true 268, seat to seat. You will lose both lift and .050 duration, but you will gain a bunch of cylinder pressure; perhaps as much as 1.5 psi per degree. If you give up 7 degrees of ramp, that calculates to 10psi, which could bring your pressure up from a mediocre 145 to say 155, hmmmmmmmmmmmm

This is of course trading away top-end power, to get bottom end power. But you can easily get that power back by resetting your valvelash to zero or less.

The downside to this is that the hydraulic lifters are now crashing into the non-existent clearance ramps, so into the acceleration ramps; and one would surmise this to shorten the life of the cam/lifters. Maybe, but I've been waiting since about 2006 for mine to give up......

Again, if you can get your cylinder pressure up to 155/160 with iron heads or 180/185 with alloy heads, in a streeter, IMO, you might as well stick with hydros. You can use your 273 gear with decent springs, to minimize the preload and thus rpm your engine to however high you dare; are you feeling lucky today? lol.

Happy NewYear !

I personally don't get the problem. Oregon HAS the 4 speed cam on file and can grind it any time. I forget, I think it's either 1 or 2 degrees off on ONE spec. @krazykuda, Karl, I forget, what is it? It's dead on unless somebody wants to be a nitpickin rivet counter. You'll never see hear or feel the difference.Like your idea of making them to factory specs (blueprint) setting up masters to do it. Then they will have the factory base circles and use the stock length mopar pushrods.

The regrind cams to the 340 4spd specs are going to have smaller base circles and will need the push rod lengths looked into.

For someone who wants a blueprinted 340 4spd cam, your price is not that bad. Was about the same price as the last of the Mopar Performance 340 cams were costing when they used to be available at the end of their production. Now no longer available.

Radical, lol It wasn't meant to be taken literally.These cams run best in High-Compression engines, or in clutch cars because of the loss of cylinder pressure at low rpm. Neither can hardly be called "radical". To get the numbers, they have really long clearance ramps.

For the 268s;

The wide LSA (114) allows the rpm to hang on at the top, I have seen dyno curves where the power plateau is about 1000rpm, which is huge! But it comes at the expense of absolute power.

Wow!! When I saw the 68 cam specs i realize my cam is close to it. It was ground by a guy who used to work for Crane.

Adv duration and lift

Int .498 exh .512

Int. 274. Exh 286

113.5 LSA

In a 360 magnum, hydraulic roller

Stock block except for the cam/Springs, locks, retainers, air gap.

Did the stock 68 cam have a nice sound to it, nice lope at idle ?? What will more lift on mine do vs the 68 ?

Sweet spot for Mine is supposed to be 2000-6000. What is it for the 68 ?

BTW, this should settle any arguement

Adv duration and lift

Int .498 exh .512

Int. 274. Exh 286

113.5 LSA

In a 360 magnum, hydraulic roller

Stock block except for the cam/Springs, locks, retainers, air gap.

Did the stock 68 cam have a nice sound to it, nice lope at idle ?? What will more lift on mine do vs the 68 ?

Sweet spot for Mine is supposed to be 2000-6000. What is it for the 68 ?

BTW, this should settle any arguement

Last edited:

The 4 speed cam has a smooth idle.

In a 340/360The 4 speed cam has a smooth idle.

scatpackbee

Well-Known Member

These were the specs Ken at Oregon Cams quoted me in an email.

221/227 @ .050", 276/309 adv, .438"/.456" lift

He also said he could grind at 112 or 114 lobe separation angle.

221/227 @ .050", 276/309 adv, .438"/.456" lift

He also said he could grind at 112 or 114 lobe separation angle.

Yes.In a 340/360

?Wow!! When I saw the 68 cam specs i realize my cam is close to it. It was ground by a guy who used to work for Crane.

Adv duration and lift

Int .498 exh .512

Int. 274. Exh 286

113.5 LSA

In a 360 magnum, hydraulic roller

Stock block except for the cam/Springs, locks, retainers, air gap.

Did the stock 68 cam have a nice sound to it, nice lope at idle ?? What will more lift on mine do vs the 68 ?

Sweet spot for Mine is supposed to be 2000-6000. What is it for the 68 ?

BTW, this should settle any arguement

View attachment 1715845984

View attachment 1715845985

Apiril 1976 DIRECT CONNECTION RACING MANUAL

-