Door Hinge Repair

The op has found out that the "rebuild kit" doesn't work without drilling out the lower hinge. Because it was never designed to use a bushing. Too weak. The lower hinge carries te weight of the door, the upper hinge only holds the top of the door in alignment.

Just drill it out like someone said and now the hinge cannot be "rebuilt" properly as you have now hogged out the pivot pin hole.

Those kits use GM pivot pins and the upper bushings from the Mopar 67 76 A-body upper hinge.

Besides drilling the hole out and you don't want to drill out both side of the hinges, there is nowhere for the bushing shoulder to go, like the upper. You will also have to file/grind one side of the hinge to make room for the bushing shoulder.

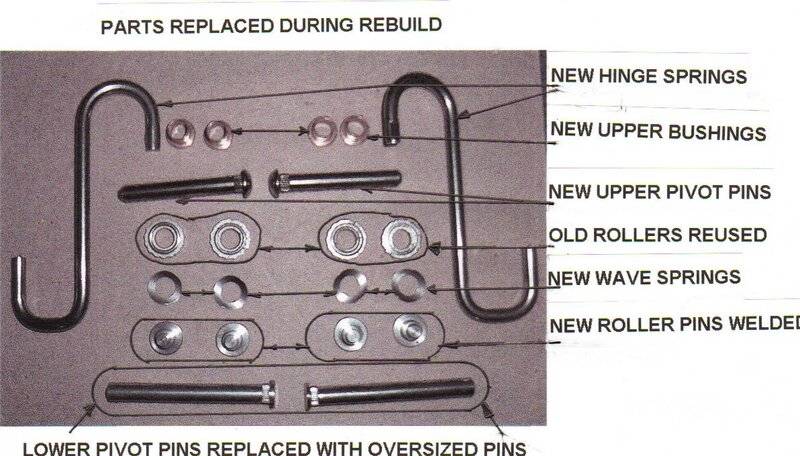

We drill the pivot hole to the smallest oversize that will make the hole round and then ream the hole to fit a custom sized pin.

Like boring a cylinder to the smallest oversize not .060 because pistons only come in that size... I will post some picture for you to see. One shows a hinge that was rebuilt with "bushings". The other shows how thin the hinge area is after drilling it out. Too weak now.And a common problem with A & B-body hinges that have cracks in the spring area.

If you want information on a professionally, rebuilt to factory specs, contact me.We also replace the roller/door check pins and springs that are commonly seized causing the main spring to fail as part of a complete rebuild. No pin,hack job.

Wonder why these "pin kits " have no instructions ?? Because they are just parts put in a bag. Mother Mopar never intended the lower to have bushings. So they won't fit without modifying the hinges.

This something you don't see until the eighties and beyond.

Leo

Member pricing.

Check my past customers here and on the other Mopar sites. Over 25 years and 1000's done.

The op has found out that the "rebuild kit" doesn't work without drilling out the lower hinge. Because it was never designed to use a bushing. Too weak. The lower hinge carries te weight of the door, the upper hinge only holds the top of the door in alignment.

Just drill it out like someone said and now the hinge cannot be "rebuilt" properly as you have now hogged out the pivot pin hole.

Those kits use GM pivot pins and the upper bushings from the Mopar 67 76 A-body upper hinge.

Besides drilling the hole out and you don't want to drill out both side of the hinges, there is nowhere for the bushing shoulder to go, like the upper. You will also have to file/grind one side of the hinge to make room for the bushing shoulder.

We drill the pivot hole to the smallest oversize that will make the hole round and then ream the hole to fit a custom sized pin.

Like boring a cylinder to the smallest oversize not .060 because pistons only come in that size... I will post some picture for you to see. One shows a hinge that was rebuilt with "bushings". The other shows how thin the hinge area is after drilling it out. Too weak now.And a common problem with A & B-body hinges that have cracks in the spring area.

If you want information on a professionally, rebuilt to factory specs, contact me.We also replace the roller/door check pins and springs that are commonly seized causing the main spring to fail as part of a complete rebuild. No pin,hack job.

Wonder why these "pin kits " have no instructions ?? Because they are just parts put in a bag. Mother Mopar never intended the lower to have bushings. So they won't fit without modifying the hinges.

This something you don't see until the eighties and beyond.

Leo

Member pricing.

Check my past customers here and on the other Mopar sites. Over 25 years and 1000's done.